A kind of preparation method and product of water-based polyurethane emulsion that temporarily protects stripping water-based screen printing ink

A technology of water-based polyurethane and screen printing ink, which is applied in the field of preparation of water-based polyurethane emulsion products and water-based polyurethane emulsion. It can solve the problems of affecting the aesthetics of the panel, the mold cannot be tightly combined with the transparent plastic panel, and the edge of the window is not neat, etc., so as to improve the stripping effect , excellent yellowing resistance, easy peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of the water-based polyurethane emulsion of the temporary protection strippable water-based screen printing ink provided by the present embodiment may further comprise the steps:

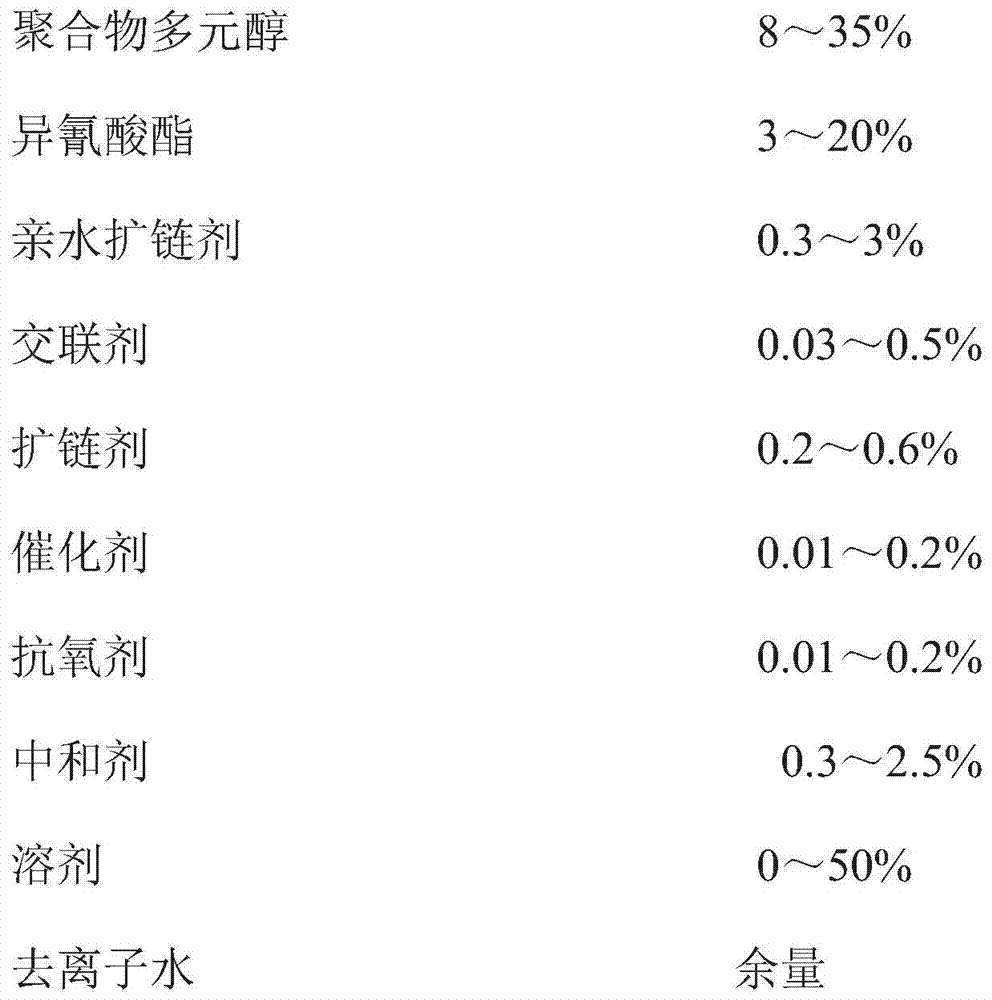

[0025] 1) Take raw materials according to the following weight percentages:

[0026]

[0027] 2) Prepare polyurethane prepolymer:

[0028] Add the accurately weighed polymer polyols and antioxidants into a reaction tank with a stirrer and a thermometer, dehydrate at 110°C-120°C and a vacuum of -0.09MPa for 2 hours, and then pass N 2 Under protection, add isocyanate and catalyst, react at 60-90°C for 1-3 hours; then add hydrophilic chain extender, cross-linking agent, solvent in the reaction tank, react at 50-70°C for 2-5 hours, Cool down to 20-50°C, add solvent to dilute to obtain polyurethane prepolymer;

[0029] 3) Prepare water-based polyurethane emulsion:

[0030] Pour all the polyurethane prepolymer obtained above into a high-speed shear disperser, add a neut...

Embodiment 2

[0036] Embodiment 2: the preparation method and water-based polyurethane emulsion provided by this embodiment are basically the same as embodiment 1, and its difference is that,

[0037] 1) Its raw material is made up of each component of following percentage by weight:

[0038]

[0039]

[0040] Described polymer polyol is polytetrahydrofuran diol;

[0041] Described isocyanate is isophorone isocyanate (IPDI);

[0042] Described hydrophilic chain extender is dimethylolpropionic acid (DMPA);

[0043] The crosslinking agent is trimethylolpropane of trifunctionality;

[0044] The chain extender is difunctional ethylenediamine;

[0045] Described catalyst is dibutyltin dilaurate;

[0046] Described antioxidant is antioxidant 1010;

[0047] Described neutralizing agent is triethylamine;

[0048] Described solvent is acetone.

[0049] 2) Prepare polyurethane prepolymer:

[0050] Add accurately weighed polymer polyols and antioxidants into a reaction tank with a stirrer ...

Embodiment 3

[0053] Embodiment 3 The preparation method and water-based polyurethane emulsion provided by the present embodiment are basically the same as those in Embodiment 1 and 2, and the difference is that

[0054] 1) Its raw material is made up of each component of following percentage by weight:

[0055]

[0056] Described polymer polyol is the polyoxypropylene glycol that molecular weight is 2000;

[0057] The isocyanate is hydrogenated MDI;

[0058] Described hydrophilic chain extender is dimethylolpropionic acid (DMPA);

[0059] The crosslinking agent is trimethylolpropane of trifunctionality;

[0060] The chain extender is difunctional ethylenediamine;

[0061] Described catalyst is stannous octoate;

[0062] Described antioxidant is antioxidant 1010;

[0063] Described neutralizing agent is triethylamine;

[0064] Described solvent is acetone.

[0065] 2) Prepare polyurethane prepolymer:

[0066] Add accurately weighed polymer polyols and antioxidants into a reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com