Electronic radiation crosslinked polymeric material for 3D printing, preparation method and product thereof

A cross-linked polymer, 3D printing technology, applied in the direction of 3D object support structure, additive processing, manufacturing tools, etc., can solve the problems of poor heat resistance and rigidity, limit the scope of application, etc., achieve chemical corrosion resistance and mechanical Increased strength, broad application prospects, and improved heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

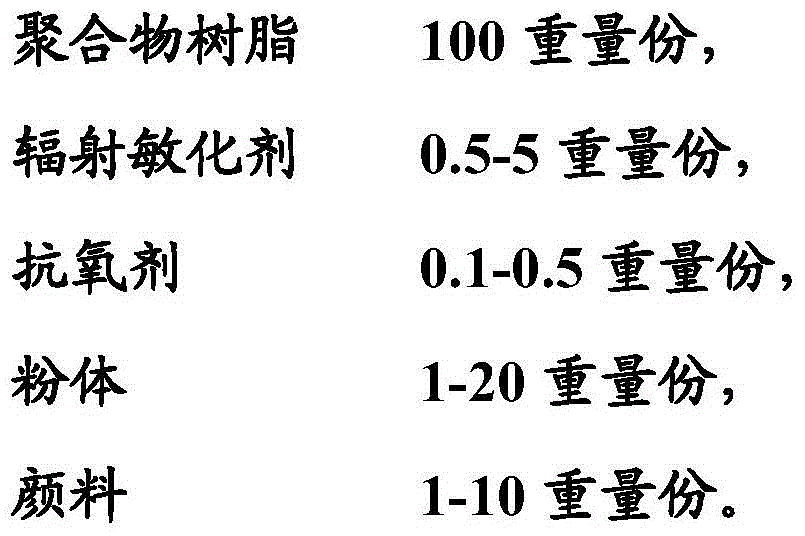

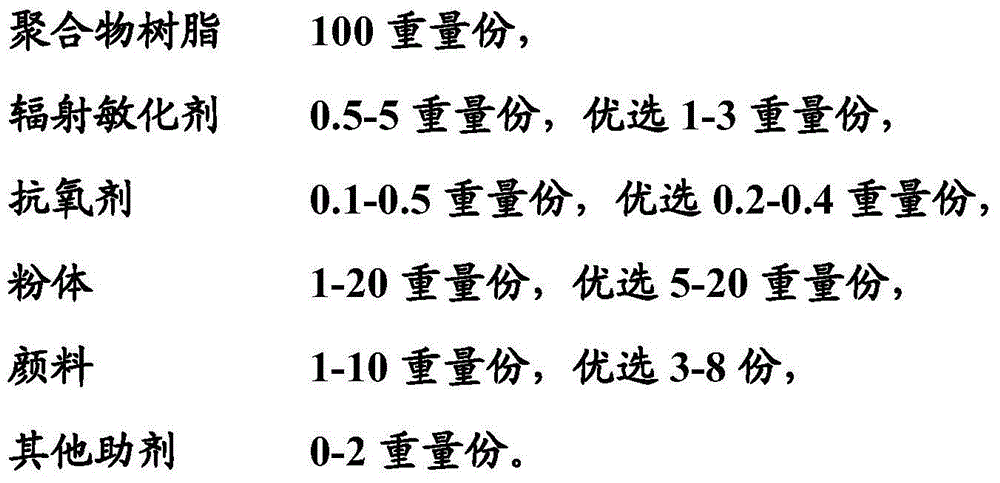

Method used

Image

Examples

Embodiment 1

[0057] 3D printed product A prepared from electron radiation crosslinked polymer composition for 3D printing and materials prepared therefrom

[0058] 1) 100 parts by weight of PE (weight average molecular weight 50,000), 0.5 part of triallyl cyanurate, 0.1 part of antioxidant 1010, 5 parts of micron calcium carbonate powder, 1 part of lead chromium Huang is mixed evenly with a single-screw extruder, extruded and processed into filaments with a diameter of 2mm, and the diameter error is within 5%. Set in sequence: 185-195°C, 190-200°C, 195-205°C, 200-210°C, 195-205°C, die head temperature 215-225°C.

[0059] 2) Feed the filament obtained in step 1) into the nozzle through the wire feeding mechanism of the UPRINT3D printer, heat and melt in the nozzle, the nozzle moves along the section profile of the part and the filling track, and at the same time extrude the molten material, using the thermal melting of the material After being extruded under computer control, it is rapidly...

Embodiment 2

[0062] 3D printed article B prepared from electron radiation crosslinked polymer composition for 3D printing and materials prepared therefrom

[0063] 1) With 100 parts by weight of PVC (weight average molecular weight 70,000), 1 part of triallyl isocyanurate, 0.2 part of antioxidant 1010, 10 parts of nano Ag powder, 2 parts of cadmium red Mix evenly with a single-screw extruder, extrude and process it into filaments with a diameter of 2mm, and the diameter error is within 5%. The settings are: 185-195°C, 190-200°C, 195-205°C, 200-210°C, 195-205°C, and the die head temperature is 215-225°C.

[0064] 2) Feed the filament obtained in step 1) into the nozzle through the wire feeding mechanism of the UPRINT3D printer, heat and melt in the nozzle, the nozzle moves along the section profile of the part and the filling track, and at the same time extrude the molten material, using the thermal melting of the material It is solidified quickly after being extruded under computer contro...

Embodiment 3

[0067] 3D printed articles prepared from electron radiation crosslinked polymer compositions for 3D printing and materials prepared therefrom

[0068] 1) with 100 parts by weight of PA (weight average molecular weight 100,000), 2 parts of trimethylolpropane trimethacrylate, 0.3 parts of antioxidant 1096, 15 parts of nano Fe 3 o 4 Powder, 3 parts of iron yellow are mixed evenly with a single-screw extruder, extruded and processed into filaments with a diameter of 2mm, the diameter error is within 5%, the screw diameter of the single-screw extruder is 70mm, and the aspect ratio is 20 : l, the temperature of the extruder is set as follows: 185-195°C, 190-200°C, 195-205°C, 200-210°C, 195-205°C, and the die head temperature is 215-225°C.

[0069] 2) Feed the filament obtained in step 1) into the nozzle through the wire feeding mechanism of the UPRINT3D printer, heat and melt in the nozzle, the nozzle moves along the section profile of the part and the filling track, and at the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com