A near-infrared long afterglow luminescent material of zinc stannate doped with trivalent chromium ions and its preparation method

A technology of ion doping and luminescent materials, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of increasing applications and staying in the luminescence band, and achieves the effects of wide selection of materials, simple preparation methods and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] According to the following composition: near-infrared long afterglow luminescent material Zn 2 SnO 4 : Cr, Zn 2 SnO 4 as the matrix, doped with Cr 3+ is the active ion, where Cr 3+ The doping amount of ions is 0.01mol%. Zinc oxide, tin oxide, and chromium oxide were weighed separately, ground and mixed, pre-fired at 800°C for 4 hours, taken out, ground again, and fired at 1350°C for 3 hours.

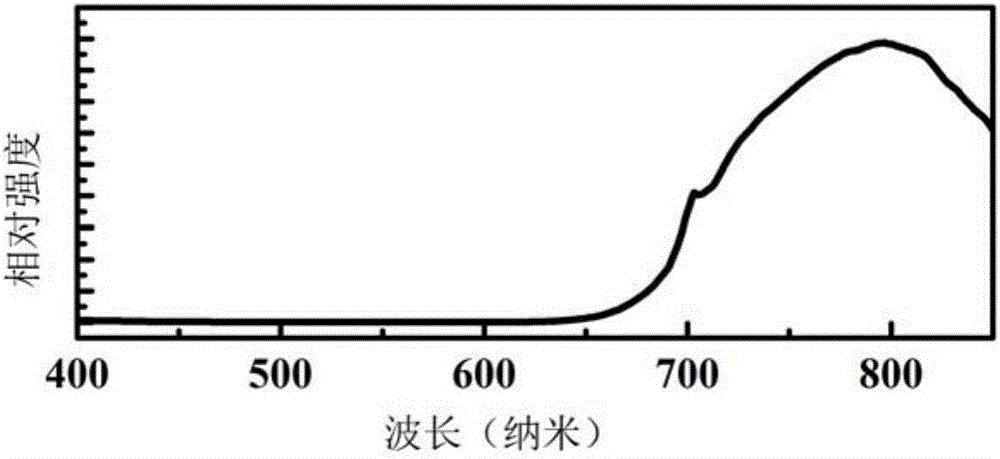

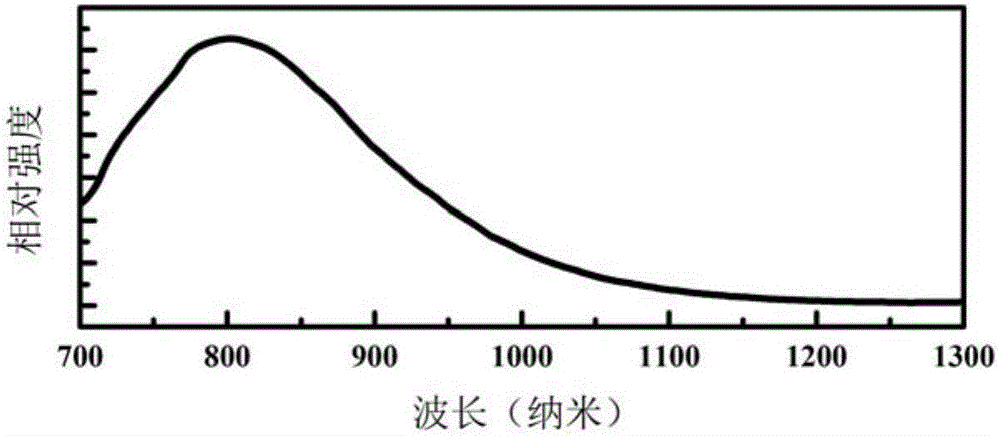

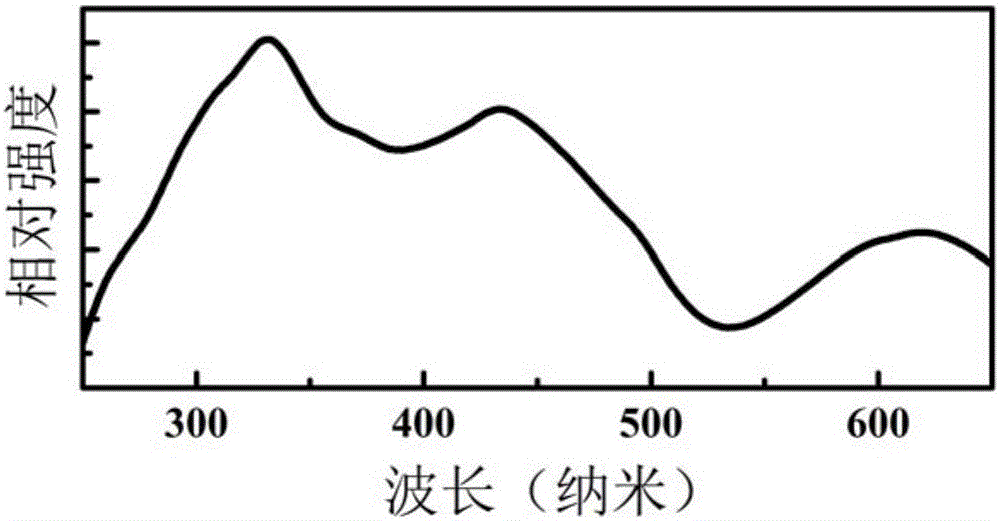

[0026] The fluorescence spectrum of the near-infrared long-lasting luminescent material prepared in this example is as follows: figure 1 with figure 2 As shown, the emission spectrum under excitation at 325nm emits fluorescence at 600nm-1200nm, and the luminescence peaks are located at 700nm and 800nm. image 3 The excitation spectra corresponding to the luminescence peaks shown in , the three excitation peaks obtained are located at 325nm, 430nm and 610nm respectively, confirming that the luminescence center is Cr ion. Figure 4 The long-lasting fluorescence spectrum of t...

Embodiment 2

[0028] According to the following composition: near-infrared long afterglow luminescent material Zn 2 SnO 4 : Cr, Zn 2 SnO 4 as the matrix, doped with Cr 3+ is the active ion, where Cr 3+ The doping amount of ions is 5mol%. Weigh zinc oxide, tin oxide, and chromium oxide respectively, grind and mix them, pre-fire at 900°C for 6 hours, take them out, grind again, and fire at 1400°C for 5 hours.

[0029] Image 6 The near-infrared long afterglow luminescent material prepared for this example was irradiated under sunlight for 10 minutes to monitor the 800nm afterglow attenuation, which showed that the material had a near-infrared long afterglow of up to 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com