Method and apparatus for separating benzaldehyde, phenylpropyl aldehyde, cinnamaldehyde, cinnamyl acetate and o-methoxycinnamaldehyde from cinnamon oil

A technology of cinnamon oil and molecular distillation, which is applied in chemical instruments and methods, fat oil/fat refining, separation/purification of carbonyl compounds, etc., can solve the problems of high cost, waste of resources, high energy consumption, etc. The effect of improving yield and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

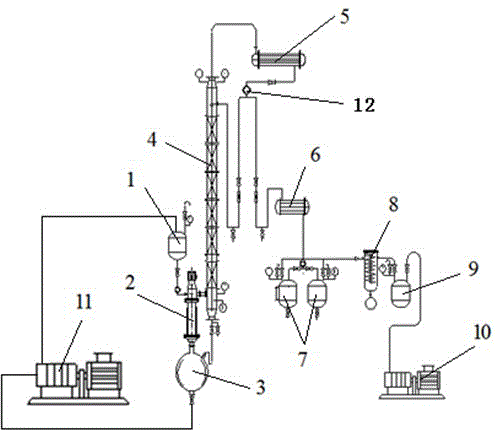

Embodiment 1

[0027] Add 500.0 g of cinnamon oil containing 1.2% benzaldehyde, 0.7% phenylpropanal, 85% cinnamaldehyde, 0.7% acetate cinnamaldehyde and 4.5% o-methoxycinnamaldehyde. Water sodium sulfate for dehydration, put the processed cinnamon oil into material tank 1, control the rectifying column temperature at 75℃, evaporation temperature at 45℃, total reflux for 30min, reflux ratio of 1.5 and vacuum degree of 200 Pa, and collect the components in this section Obtain 3.2g of benzaldehyde with a purity of 63.2%; increase the rectifying column temperature to 85°C, evaporation temperature 55°C, total reflux for 40min, reflux ratio of 2.5 and vacuum degree of 130Pa, collect the components in this section, and obtain 1.8g with a purity of 51.4 % Phenylpropanal; keep the distillation column temperature 85℃, increase and control the evaporation temperature 80℃, total reflux 40 min, reflux ratio 3 and vacuum degree 50 Pa, collect 370.0g cinnamon with 99.5% purity in this section Aldehydes; inc...

Embodiment 2

[0030] Add 500.0 g of cinnamon oil containing 1.2% benzaldehyde, 0.7% phenylpropanal, 85% cinnamaldehyde, 0.7% acetic acid cinnamaldehyde, and 4.5% o-methoxycinnamaldehyde, and add 45g Water sodium sulfate is dehydrated, the processed cinnamon oil is put into material tank 1, and the material tank 1 of the molecular distillation and rectification coupling device is added to control the temperature of the rectification column, the evaporation temperature, the reflux ratio, the degree of vacuum, and the rectification conditions. As follows: distillation column temperature 78℃, evaporation temperature 40℃, total reflux 35min, reflux ratio 2 and vacuum degree 220Pa. Collect the components in this section to obtain 3.1g of benzaldehyde with a purity of 61.7%; increase the distillation column temperature by 82 ℃, evaporation temperature 60℃, total reflux 48min, reflux ratio 3 and vacuum degree 120Pa, collect the components in this section, obtain 1.92g phenylpropanal with a purity of ...

Embodiment 3

[0033] Add 500.0g of cinnamon oil with 1.2% benzaldehyde content, 0.7% phenylpropanal content, 85% cinnamaldehyde content, 0.7% acetate cinnamaldehyde content, and 4.5% o-methoxycinnamaldehyde content. Water sodium sulfate is dehydrated, the processed cinnamon oil is put into material tank 1, and the material tank 1 of the molecular distillation and rectification coupling device is added to control the temperature of the rectification column, the evaporation temperature, the reflux ratio, the degree of vacuum, and the rectification conditions. As follows: distillation column temperature 80℃, evaporation temperature 50℃, total reflux 40 min, reflux ratio 1.5 and vacuum degree 180 Pa. Collect the components in this section to obtain 3.6g of benzaldehyde with a purity of 66.0%; raise the distillation column Temperature 88℃, evaporating temperature 68℃, total reflux 40 min, reflux ratio 3 and vacuum degree 110Pa, collect the components in this section, obtain 2.06g phenylpropanal wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com