Method for analyzing composite type sodium polysulfide in aluminum alloy alkalization milling liquid

A sodium polysulfide and composite technology, which is applied in the direction of chemical analysis by precipitation, can solve the problems of large analysis error, inaccurate analysis, large error, etc., and achieve the effect of accurate results and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

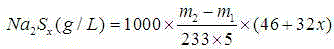

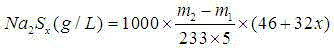

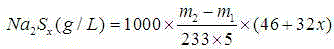

Image

Examples

Embodiment 1

[0021] The basic process formula of aluminum alloy alkaline milling fluid:

[0022] Sodium hydroxide: 160 g / L

[0023] Sodium persulfide: 25.0001g / L

[0024] Triethanolamine: 40 g / L

[0025] Additive A: 0.3 g / L

[0026] Additive B: 0.3 g / L

[0027] Aluminum ion: 10 g / L

[0028] Analysis steps:

[0029] (1) Reagent preparation: Prepare 10% analytically pure BaCl 2 Solution, filtered; mass fraction 20% analytically pure NaClO 4 solution;

[0030] (2) Sampling: Pipette 5 mL of the chemical milling solution after standing in a beaker, and then pipette 20 mL of NaClO 4 solution in a conical flask.

[0031] (3) Oxidation: Slowly pour 5 mL of chemical milling solution into the Erlenmeyer flask, shake well, and rinse the beaker 3-4 times. In order to confirm that all sodium polysulfide is converted into SO 4 2- , heat the solution to boil for 3~5 min;

[0032] (4) Precipitation: After the solution is cooled to room temperature, filter it with quantitative analysis filter ...

Embodiment 2

[0043] The basic process formula of aluminum alloy alkaline milling fluid:

[0044] Sodium hydroxide: 180 g / L

[0045] Sodium sulfide: 25.0008g / L

[0046] Triethanolamine: 45 g / L

[0047] Additive A: 0.3 g / L

[0048] Additive B: 0.3 g / L

[0049] Aluminum ion: 30 g / L

[0050] Analysis steps:

[0051] (1) Reagent preparation: Prepare 10% analytically pure BaCl 2 Solution, filtered; mass fraction 20% analytically pure NaClO 4 solution;

[0052] (2) Sampling: Pipette 5 mL of the chemical milling solution after standing in a beaker, and then pipette 20 mL of NaClO 4 solution in a conical flask.

[0053] (3) Oxidation: Slowly pour 5 mL of chemical milling solution into the Erlenmeyer flask, shake well, and rinse the beaker 3-4 times. In order to confirm that all sodium polysulfide is converted into SO 4 2- , heat the solution to boil for 3~5 min;

[0054] (4) Precipitation: After the solution is cooled to room temperature, filter it with quantitative analysis filter pap...

Embodiment 3

[0065] The basic process formula of aluminum alloy alkaline milling fluid:

[0066] Sodium hydroxide: 200 g / L

[0067] Sodium tetrasulfide: 25.0006g / L

[0068] Triethanolamine: 50 g / L

[0069] Additive A: 0.3 g / L

[0070] Additive B: 0.3 g / L

[0071] Aluminum ion: 50 g / L

[0072] Analysis steps:

[0073] (1) Reagent preparation: Prepare 10% analytically pure BaCl 2 Solution, filtered; mass fraction 20% analytically pure NaClO 4 solution;

[0074] (2) Sampling: Pipette 5 mL of the chemical milling solution after standing in a beaker, and then pipette 20 mL of NaClO 4 solution in a conical flask.

[0075] (3) Oxidation: Slowly pour 5 mL of chemical milling solution into the Erlenmeyer flask, shake well, and rinse the beaker 3-4 times. In order to confirm that all sodium polysulfide is converted into SO 4 2- , heat the solution to boil for 3~5 min;

[0076] (4) Precipitation: After the solution is cooled to room temperature, filter it with quantitative analysis filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com