Method and device for testing active coke desulfurization and denitration performance characterization

A technology for desulfurization, denitrification, and characterization testing, which is applied in measurement devices, instruments, scientific instruments, etc., can solve problems such as immature technology, low efficiency, and complex process technology routes, so as to reduce the interference of human factors, simplify operation, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

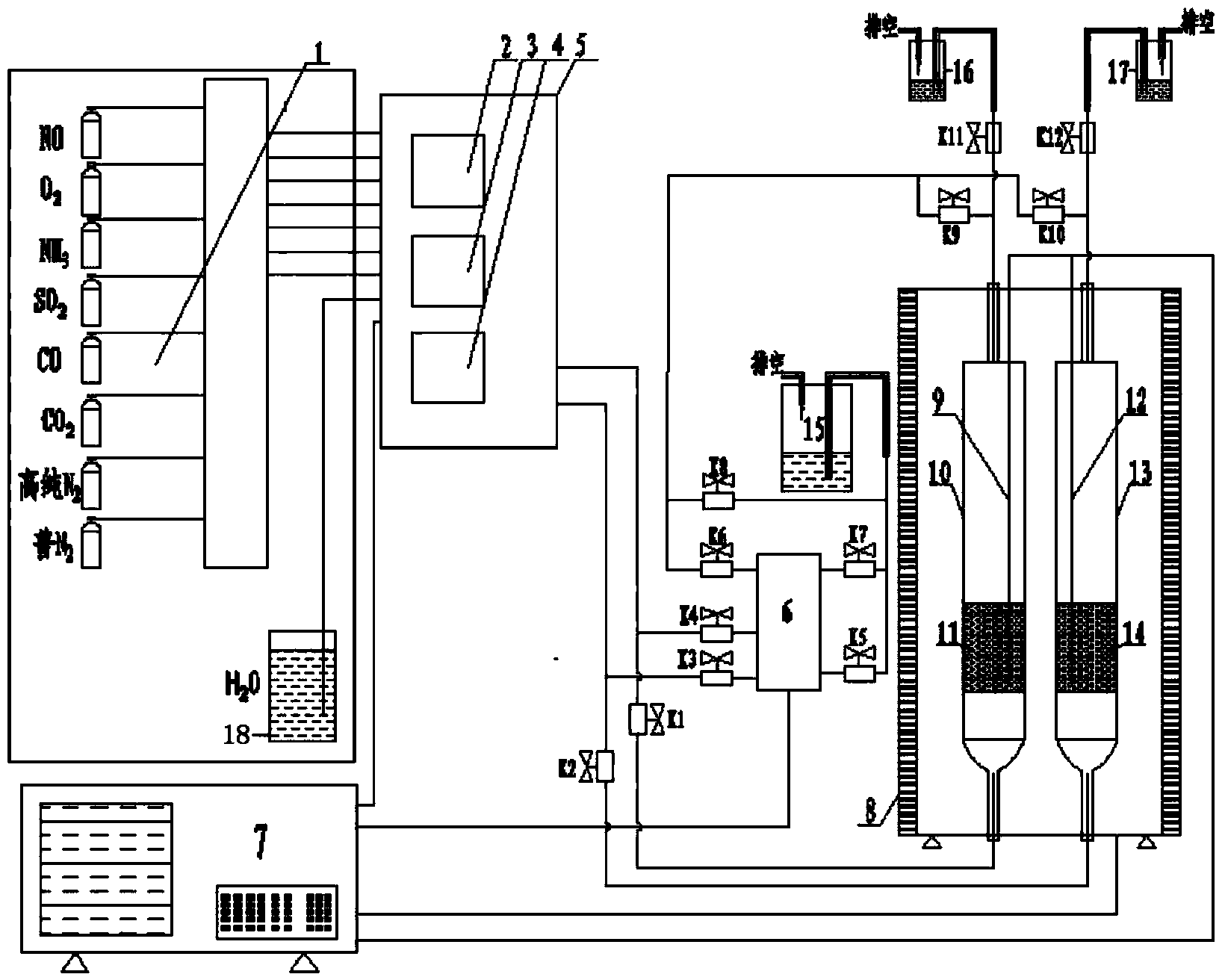

Image

Examples

Embodiment 1

[0047] Take a sample of activated coke with a diameter of 9 mm produced by an activated coke plant, and perform desulfurization performance characterization and testing: add gas to the simulated gas source system 1, and adjust the total flow of simulated flue gas in the simulated flue gas automatic gas distribution system 5 to be 0.5L / min (standard condition), in which SO 2 The volume fraction is 0.05% (dry); O 2 4% by volume (dry); CO 2 Volume fraction 1-10%; H 2 O volume fraction is 3%; the rest is N 2 . Put the weighed activated coke sample into the simulated reactor system of the heating reaction furnace for adsorption reaction, the temperature is 70°C, and the adsorption reaction time is 0.5h. The average desulfurization efficiency of the same sample tested in parallel was 94%.

Embodiment 2

[0049] Take a sample of activated coke with a diameter of 9 mm produced by an activated coke plant, and perform desulfurization performance characterization and testing: add gas to the simulated gas source system 1, and adjust the total flow of simulated flue gas in the simulated flue gas automatic gas distribution system 5 to be 50L / min (standard condition), in which SO 2 The volume fraction is 2% (dry); O 2 12% by volume (dry); CO 2 Volume fraction 1-10%; H 2 O volume fraction is 14%; the rest is N 2 . The weighed activated coke sample was put into a simulated reactor system of a heating reaction furnace for adsorption reaction at a temperature of 180°C and an adsorption reaction time of 24h. The average desulfurization efficiency of the same sample tested in parallel was 94%.

Embodiment 3

[0051] Take a sample of activated coke with a diameter of 5 mm produced by an activated coke factory, and characterize and test its denitration performance: adjust the total flow of simulated flue gas to 0.5L / min (standard condition), and the NO volume fraction is 100ppm (dry); NH3 volume fraction is 100ppm (dry), CO volume fraction is 50ppm; O 2 The volume fraction is 4% (dry), H 2 O volume fraction is 3%, the rest is N 2 . The reaction temperature was 60°C. The reaction time was 2h. The same sample was tested in parallel and its denitration efficiency was 84.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com