MEMS capacitor switch with PN junction

A technology of capacitive switch and PN junction, which is applied in the field of electronic science, can solve the problems of applying large electrostatic force, high series impedance, and the switch cannot be released, so as to improve reliability and stability, ensure close contact, and avoid bonding failure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

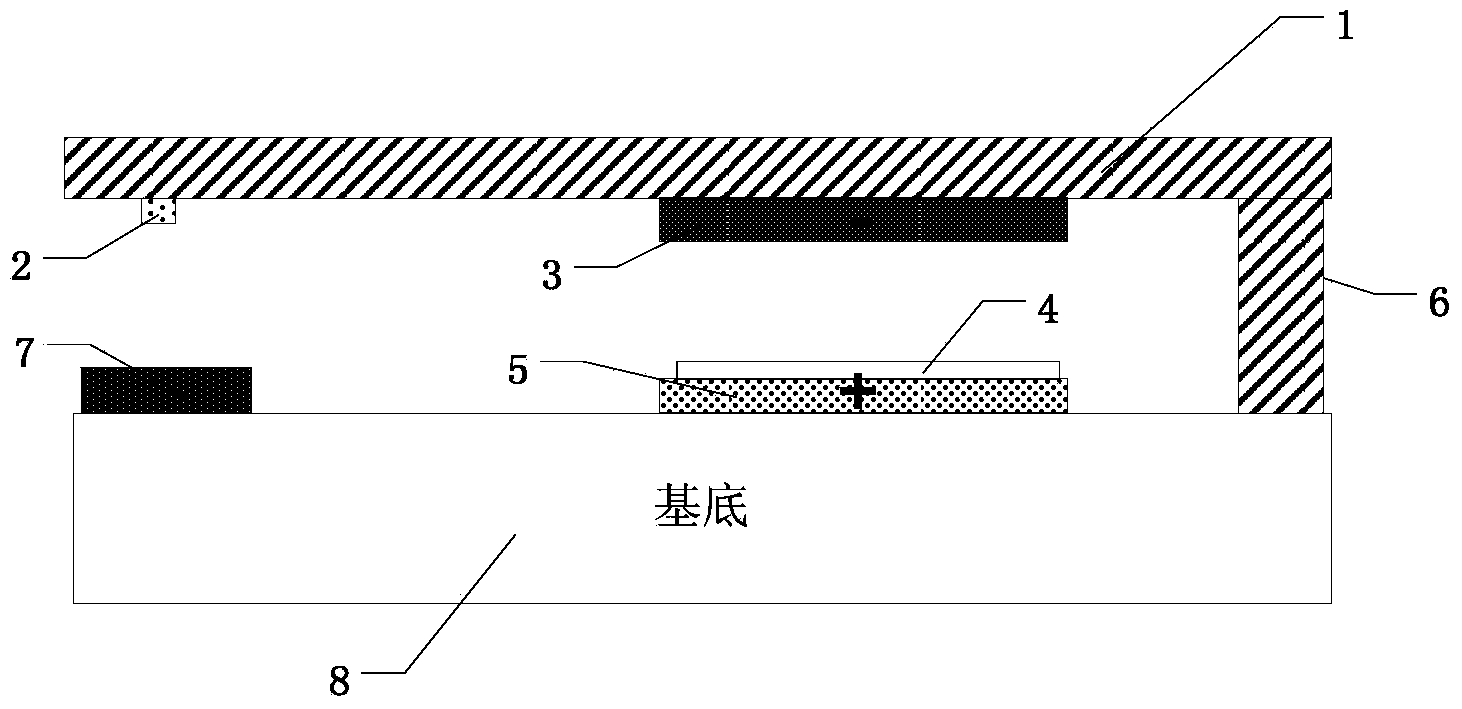

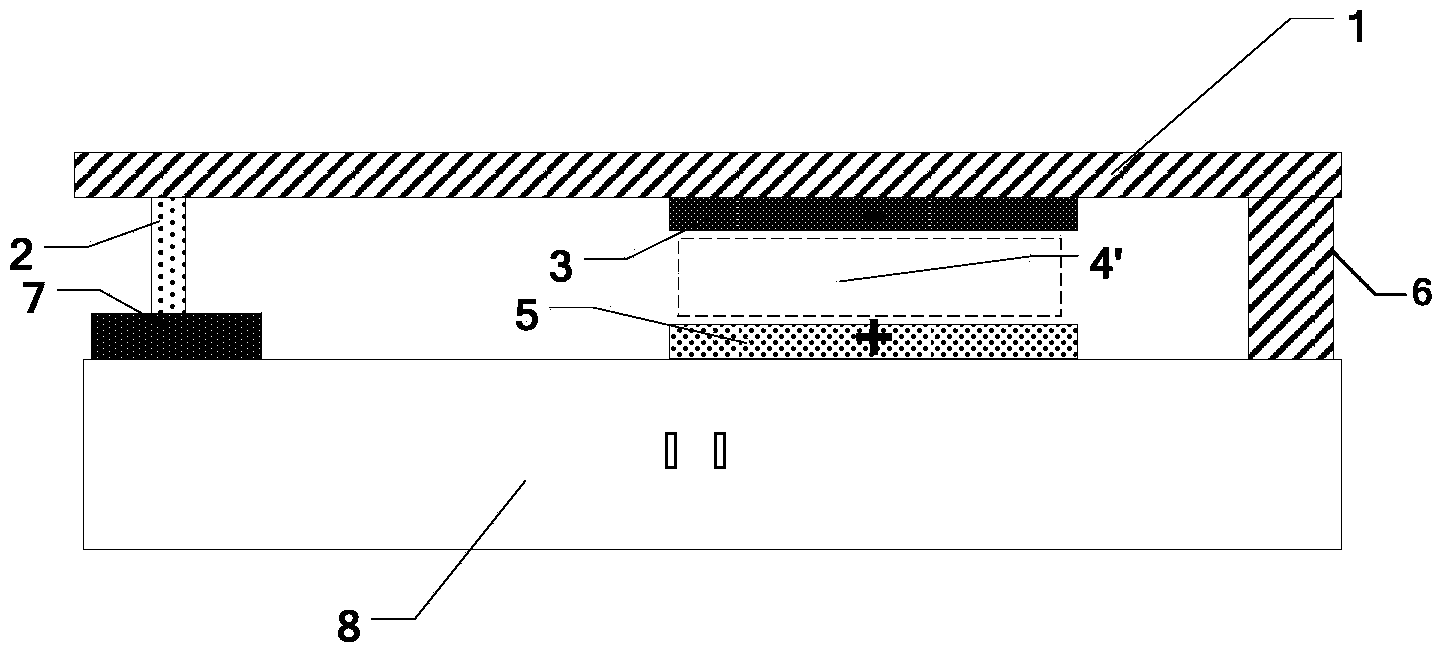

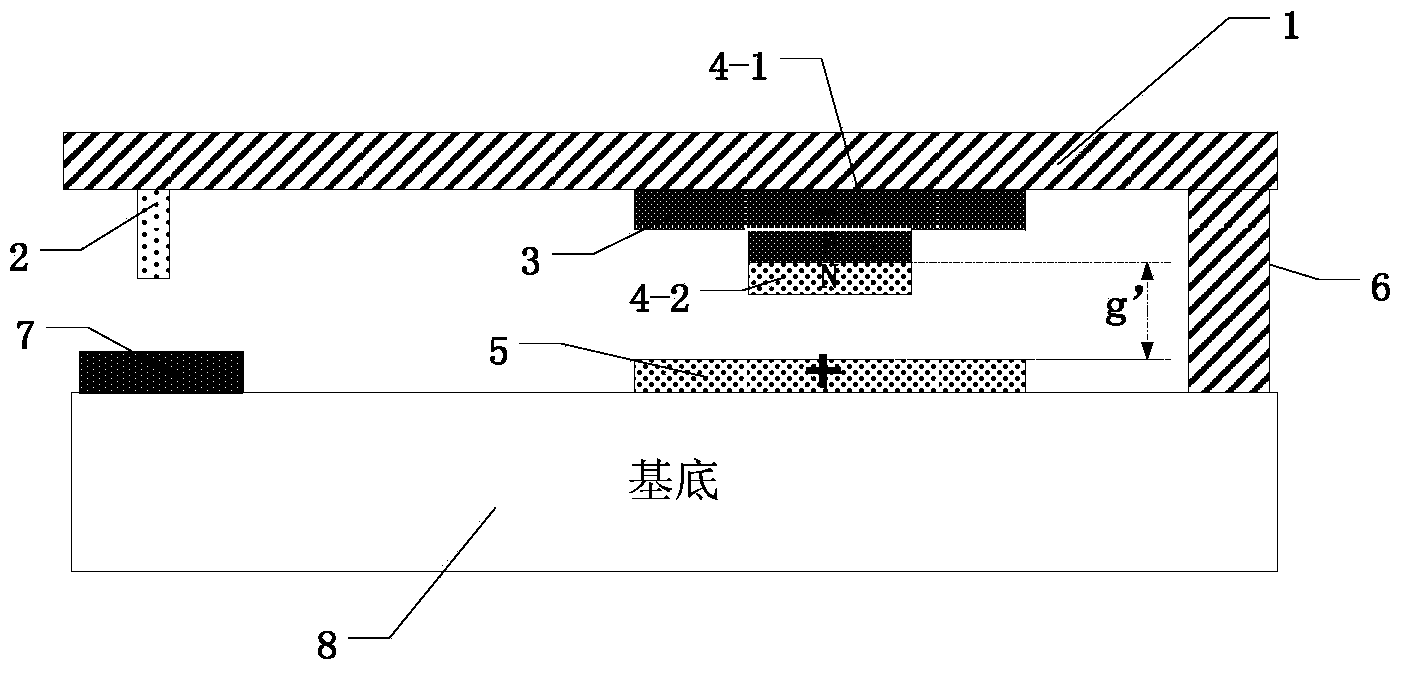

[0034] Below in conjunction with accompanying drawing, the present invention will be further described. Such as Figure 3 to Figure 5 as shown,

[0035] A MEMS capacitive switch with a PN junction, comprising a cantilever beam 1 and a signal line 7 arranged on the surface of a substrate substrate 8, one end of the cantilever beam 1 is fixed on the substrate substrate 8 by an anchor point 6, and the cantilever beam 1 The other end is provided with an electrical contact point 2 capable of connecting two sections of signal lines 7; a lower drive electrode 5 is provided on the surface area of the substrate substrate 8 between the signal line 7 and the anchor point 6, correspondingly on the cantilever beam 1 The area between the anchor point 6 and the electrical contact point 2 is provided with an upper driving electrode 3, and there is a vertical semiconductor PN junction composed of a P-type semiconductor 4-1 and an N-type semiconductor 4-2 between the upper and lower driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com