Cotton no-tillage summer direct seeding cultivation method

A cultivation method and cotton technology, applied in the fields of botanical equipment and methods, horticulture, application, etc., can solve the problems of reduction of arable land, increase of material input, reduction of labor force, etc., and achieve reasonable accumulation and distribution of nutrients and efficiency of fertilizer utilization. The effect of improving and improving the efficiency of nutrient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: (basic embodiment)

[0041] A kind of cultivation method of no-till direct seeding after cotton oil, its steps are as follows:

[0042] (1) Variety and seed selection: choose conventional cotton varieties or high-generation seeds of hybrid cotton varieties, which require high yield, high quality, disease resistance, insect resistance, and high purity; choose refined and coated seeds, which require full grain, high purity, and germination Strong potential, high germination rate;

[0043] (2) Sowing time: During May 10-31, no-tillage or hopeful sowing, that is, when the soil moisture is good or before the rainfall, artificially or mechanically sow cotton seeds on demand, 3-4 grains per hole, each 667m 2 Sowing 4000-5000 holes, one seedling per hole. Low density (4000-4300 holes / 667m) for sowing before May 20 2 ), high density (4600-5000 holes / 667m) for sowing after May 20 2 );

[0044] (3) Chemical weeding: after sowing, every 667m 2 Evenly spray 150...

Embodiment 2

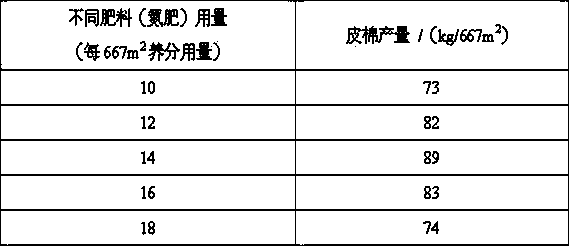

[0050] According to the basic steps of embodiment 1, the fertilizer consumption described in this embodiment is every 667m 2 Urea (46%N) 30kg (14kg pure nitrogen), superphosphate (12%P 2 o 5 ) 35kg (4.2kg P 2 o 5 ), potassium chloride (60%K 2 O) 23kg (14kg K 2 O), borax (10%B) 1kg (0.1kgB). Other implementation steps are the same as in Example 1.

Embodiment 3

[0051] Embodiment 3: (application embodiment 1)

[0052] From 2009 to 2010 in Tianmen City, Hubei Province, China, a test was carried out on the high-yield cultivation method of cotton no-tillage and direct seeding in summer, and the second-generation seeds of Huazamian H318 (a variety approved by the National Crop Variety Approval Committee, suitable for planting in the cotton area of the Yangtze River Basin) were selected. . The specific test methods for the application of herbicides, regulators, fertilizers and other products in the high-yield cultivation method of cotton no-tillage and direct seeding in summer are as follows:

[0053] (1) The previous crops were rapeseed and cotton, which were planted in compartments with a compartment width of 1.8 m and a ditch depth and width of 0.3 m;

[0054] (2) Select Huazamian H318, a high-yield and high-quality cotton variety with good disease resistance and insect resistance, concentrated boll formation, and smooth boll openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com