Preparation method of flax protein powder

A protein powder and flax technology, applied in the protein composition of vegetable seeds, plant protein processing, protein food ingredients, etc., can solve the problems of limited economic value and failure to attract enough attention, and prevent heart and cerebrovascular diseases , reduce serum cholesterol, increase the effect of nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

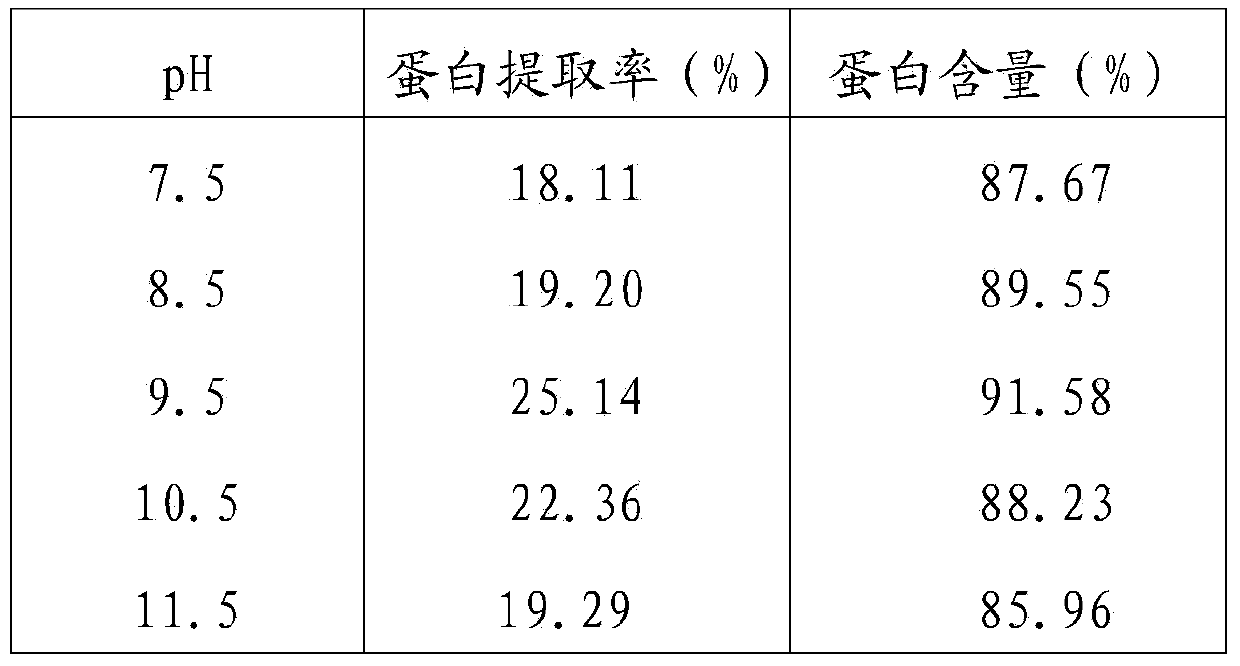

[0020] Embodiment 1: The influence of extracting liquid pH value on isolate protein extraction rate and protein content

[0021] 1. Test method

[0022] In the test, 5 treatment groups were established according to the pH value of the sodium hydroxide solution, and the pH value was respectively 7.5, 8.5, 9.5, 10.5, and 11.5. The specific steps of each group of experiments were as follows:

[0023] The defatted flax cake is crushed through a 100-180 mesh sieve, 100g of the sieve is taken, dissolved in 1000g of water, 22g of animal protein hydrolysis compound enzyme is added, shaken in a water bath at 40-60°C for 120min, filtered, and hydrogen is added to the filtrate Sodium oxide solution, the pH values are 7.5, 8.5, 9.5, 10.5, 11.5 respectively, the mass ratio of the filtrate to the sodium hydroxide solution is 1:30, leaching at 60°C for 60 minutes, centrifuging, taking the supernatant and adding hydrochloric acid aqueous solution , control the pH to 5, precipitate out, cen...

Embodiment 2

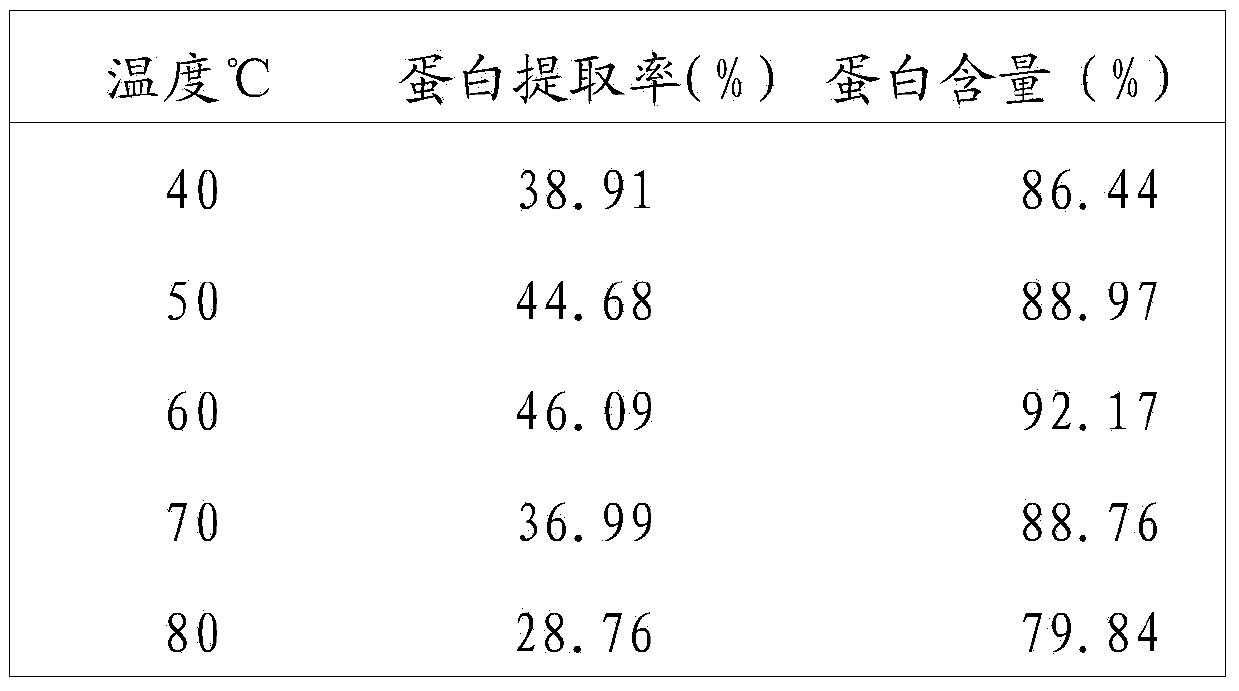

[0030] Embodiment 2: The influence of extraction temperature on protein isolate extraction rate and protein content

[0031] 1. Test method

[0032] In the experiment, 5 treatment groups were set up according to the different extraction temperatures. The extraction temperatures were 40°C, 50°C, 60°C, 70°C, and 80°C. The specific steps of each group of experiments are as follows:

[0033] The defatted flax cake is crushed through a 100-180 mesh sieve, 100g of the sieve is taken, dissolved in 1000g, added with 22g of animal proteolytic compound enzyme, shaken in a water bath at 40-60°C for 120min, filtered, and added to the filtrate Sodium hydroxide solution with a value of 9.5, the mass ratio of filtrate to sodium hydroxide solution is 1:30, the extraction temperature is 40°C, 50°C, 60°C, 70°C, 80°C, leaching for 60min, and centrifuged , taking the supernatant and adding hydrochloric acid aqueous solution, controlling the pH to 5, separating out the precipitate, centrifuging, ...

Embodiment 3

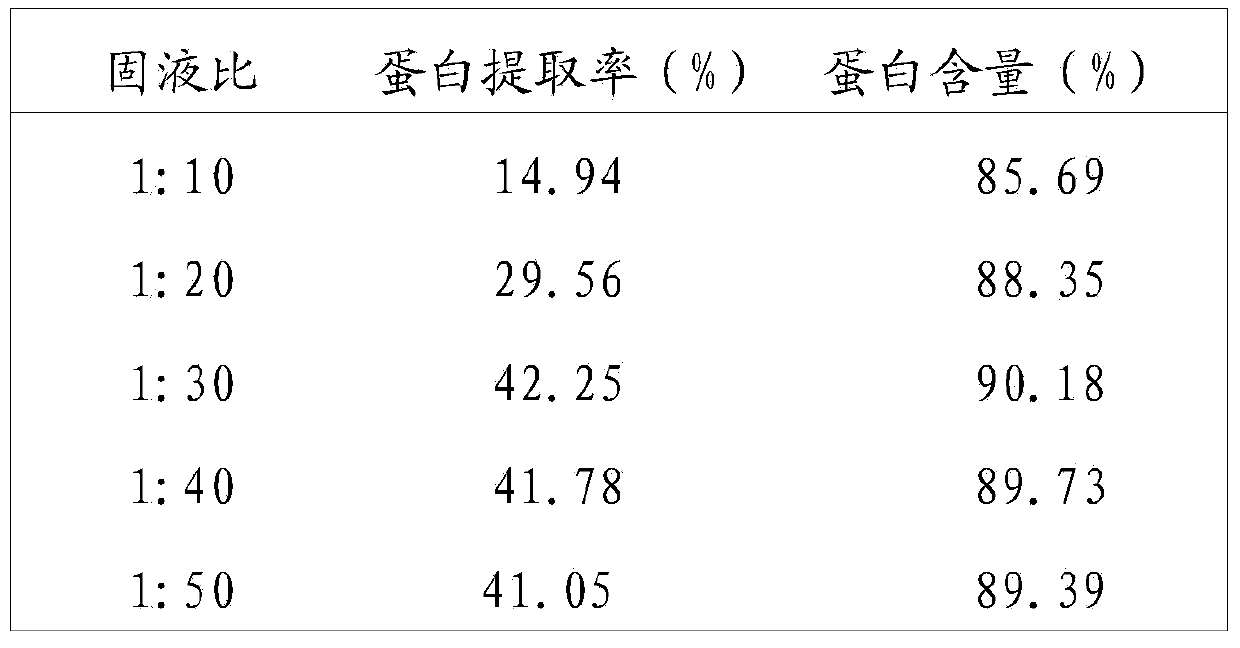

[0040] Embodiment 3: The effect of solid-liquid ratio on protein isolate extraction rate and protein content

[0041] 1. Test method

[0042] In the test, 5 treatment groups were set up according to the mass ratio of the filtrate to the sodium hydroxide solution, and the mass ratios were 1:10, 1:20, 1:30, 1:40, and 1:50. The specific steps of each group of experiments were as follows :

[0043]The defatted flax cake is crushed through a 100-180 mesh sieve, 100g of the sieve is taken, dissolved in 1000g, added with 22g of animal proteolytic compound enzyme, shaken in a water bath at 40-60°C for 120min, filtered, and added to the filtrate Sodium hydroxide solution with a value of 9.5, the mass ratio of the filtrate to the sodium hydroxide solution is 1:10, 1:20, 1:30, 1:40, 1:50, the extraction temperature is 60°C, and the extraction temperature is 60°C. After 60 minutes, centrifuge, take the supernatant and add hydrochloric acid aqueous solution, control the pH to 5, precipit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com