A non-emission finished product air-cooled blowing heat regenerative drying process

A drying process and thermal regeneration technology, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of reducing device working efficiency, compressed gas venting noise, increasing equipment and funds, etc., to achieve safe use, eliminate Effects of noise reduction and regeneration cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

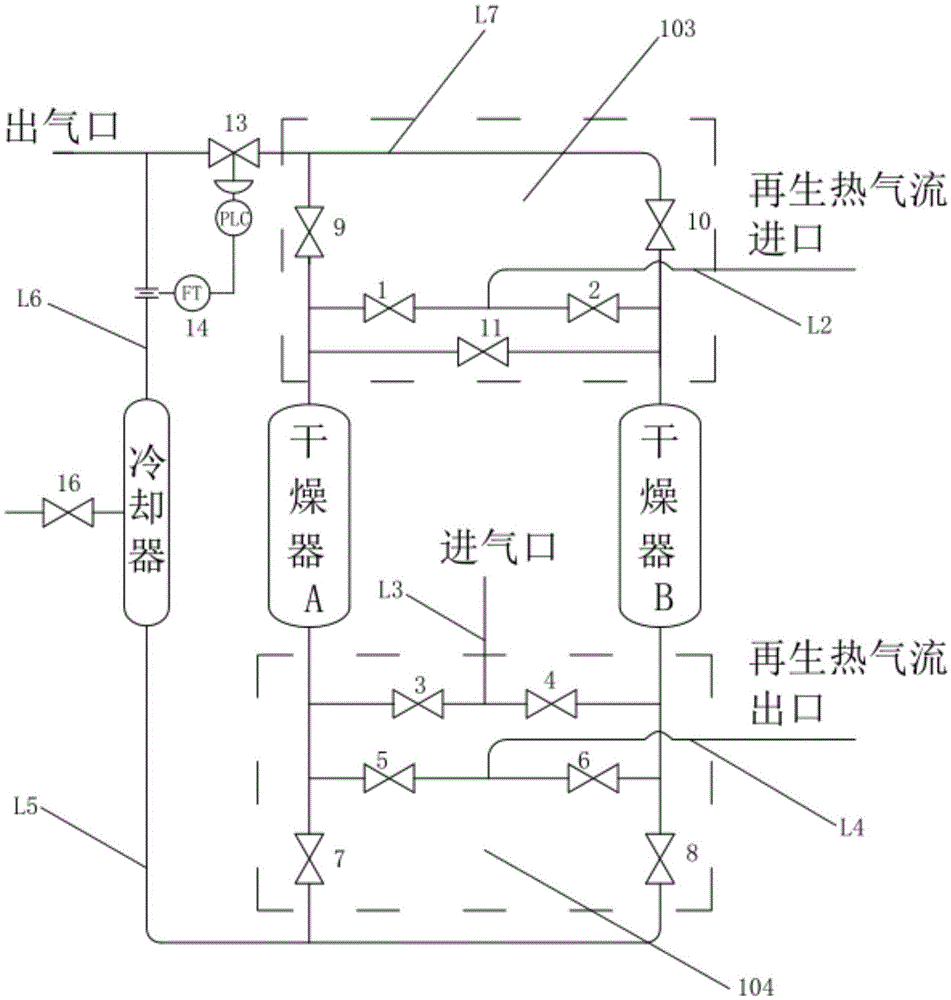

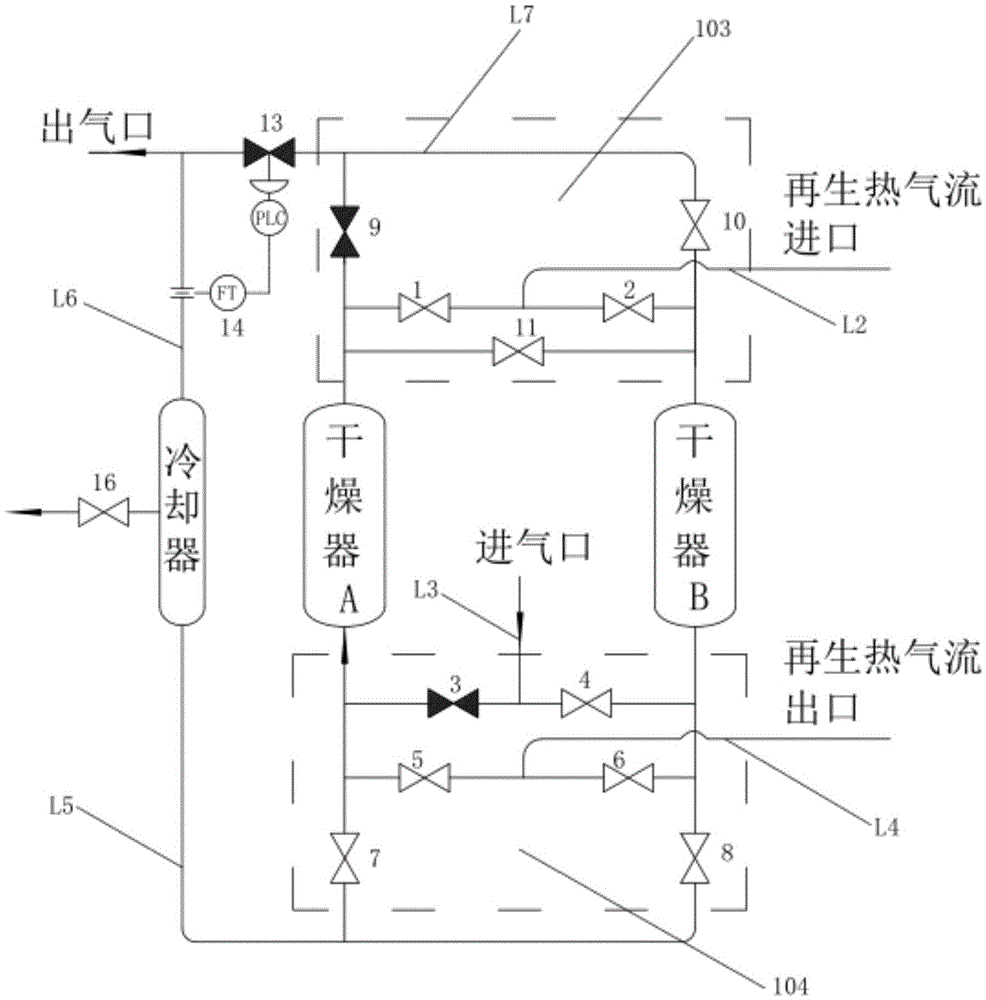

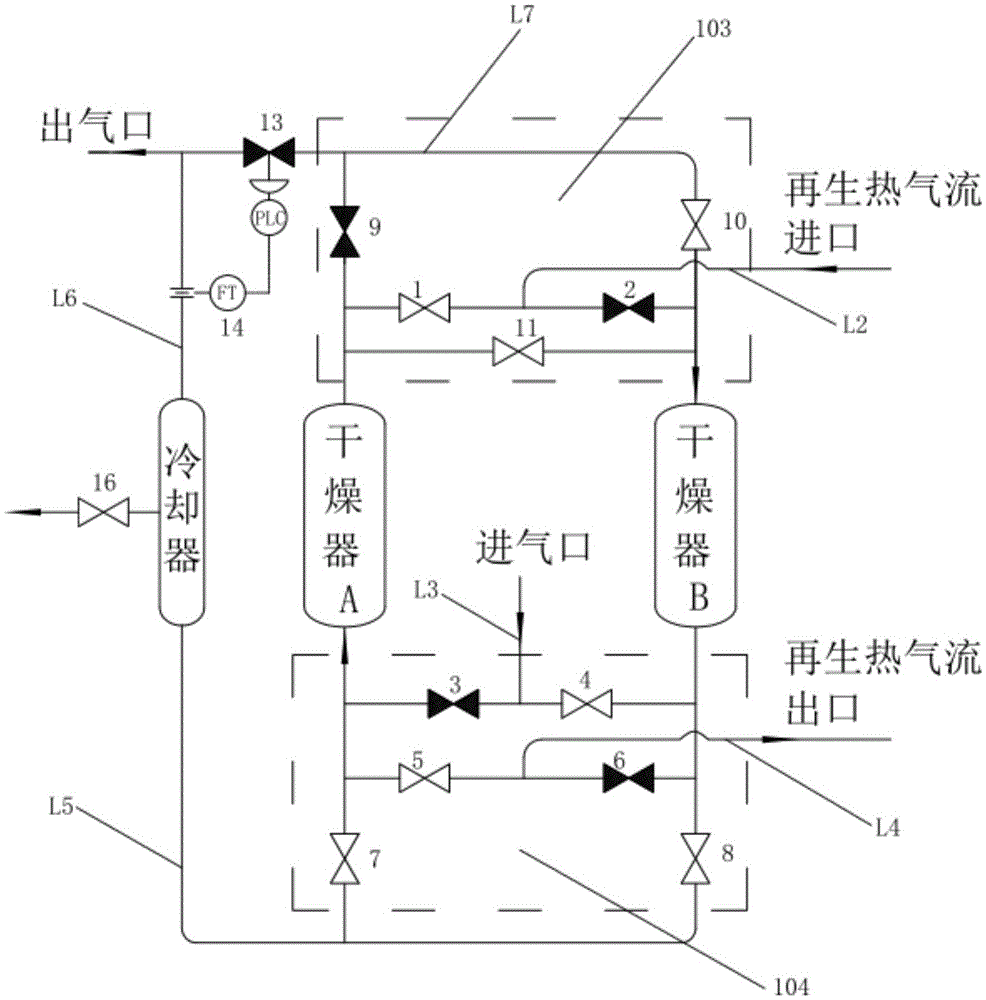

[0028] A non-emission finished product air-cooled blowing heat regeneration drying process of the present invention comprises the following steps:

[0029] (1) Adsorption: introduce the compressed gas into the adsorbent for adsorption work, absorb the dried compressed gas, and discharge it to the gas outlet as finished gas;

[0030] (2) Regeneration:

[0031] (2.1) Introduce the regenerated hot air flow into the adsorbent for regeneration, and the regenerated hot air flow heats the adsorbent to desorb and regenerate the adsorbent; the obtained wet regenerated hot air flow is discharged or refluxed after treatment;

[0032] (2.2) After heating the adsorbent for a period of time in step (2.1), introduce part of the product gas obtained in step (1) into the adsorbent for regeneration, so that the adsorbent is regenerated by cold blowing and cooled for the next half cycle use, and get hot cold blowing gas; the hot cold blowing gas is condensed, and the gas obtained is discharged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com