A kind of azo dye adsorbent and its application

An azo dye and adsorbent technology, which is applied in the field of environmental engineering to achieve the effects of large adsorption capacity, increased specific surface area and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

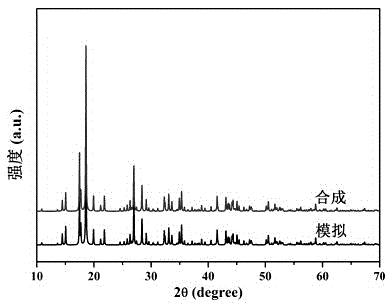

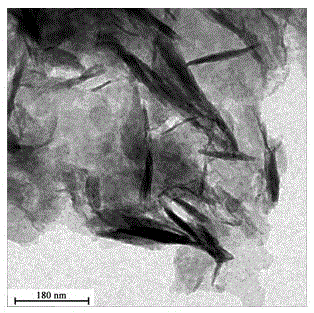

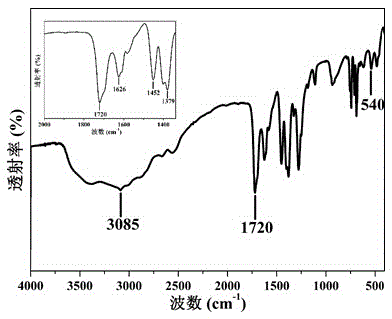

[0040] A method for synthesizing an azo dye adsorbent with strong adsorption capacity, the solvent used in the step (1) is 2.5ml of water and 2.5ml of ethanol. In step (2), 1,3,5-benzenetricarboxylic acid (solid) is 0.1050g (0.5mmol), in step 3) FeCl trichloride 3 (Solution) was 5ml (0.5mmol). TEM pictures were obtained in JEOL2010 with an accelerating voltage of 200kV. The morphology of the adsorbent determined by the electron microscope is a sheet structure with a thickness of 10-15nm. The measured specific surface area is 80g / m 2 . X-ray powder diffraction determined that the powder diffraction of the synthesized adsorbent had very high intensity at 2θ=19° and 2θ=27°. The infrared spectrum was measured by an infrared spectrometer (Nicolet5700FT-IR). Infrared spectrum at 1720cm -1 Strong absorption at , indicating that the nitrogen-containing dye adsorbent has a carboxylated surface structure.

Embodiment 2

[0042] A method for synthesizing an azo dye adsorbent with strong adsorption capacity, the solvent used in step 1) is 20ml of water and 20ml of ethanol. In step (2), 1,3,5-benzenetricarboxylic acid (solid) is 0.4200g (2mmol), in step 3) FeCl 3 (Solution) was 20ml (2mmol). TEM pictures were obtained in JEOL2010 with an accelerating voltage of 200kV. The morphology of the adsorbent determined by transmission electron microscopy is a sheet structure with a thickness of 10-15nm. The measured specific surface area is 80g / m 2 . X-ray powder diffraction determined that the powder diffraction of the synthesized adsorbent had very high intensity at 2θ=19° and 2θ=27°. The infrared spectrum was measured by an infrared spectrometer (Nicolet5700FT-IR). Infrared spectrum at 1720cm -1 Strong absorption at , indicating that the nitrogen-containing dye adsorbent has a carboxylated surface structure.

Embodiment 3

[0044] A method for synthesizing an azo dye adsorbent with strong adsorption capacity, the solvent used in step 1) is 80ml of water and 80ml of ethanol. In step (2), 1,3,5-benzenetricarboxylic acid (solid) is 0.8400g (4mmol), in step 3) FeCl 3 (Solution) was 160ml (4mmol). TEM pictures were obtained in JEOL2010 with an accelerating voltage of 200kV. The morphology of the adsorbent determined by transmission electron microscopy is a sheet structure with a thickness of 10-15nm. The measured specific surface area is 80g / m 2. The powder diffraction of the synthesized adsorbent is determined by X-ray powder diffraction at 2θ=19° and 2θ=27° with very high intensity. The infrared spectrum was measured by an infrared spectrometer (Nicolet5700FT-IR). Infrared spectrum at 1720cm -1 There is a strong absorption at , indicating that the azo dye adsorbent has a carboxylated surface structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com