Glass powder for solar cell right side silver paste

A solar cell and glass powder technology, applied in the field of glass powder, can solve the problems of low electrode adhesion and high ohmic contact resistance of cells, and achieve the effect of dense electrodes, not easy to bond, and good sintering activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

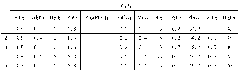

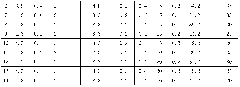

[0019] The percentage by weight of the glass frit raw material used in the present invention in the total glass composition is listed in Table 1, wherein the zinc compound and bismuth compound are also listed in the table.

[0020] Each component and consumption of table 1 embodiment 1-14 glass frit

[0021]

[0022]

[0023] The preparation steps of the glass powder adopted in the present invention are:

[0024] (1) Accurately weigh the glass frits of each component according to the requirements of the formula, mix them evenly in a mortar, and put them in a drying oven with circulating ventilation. The drying temperature is controlled at 90-150°C for 30 minutes. This process is quite It is used to pre-fire the glass frit and evaporate part of the water at the same time;

[0025] (2) Pour the glass frit to be fired into a platinum alloy crucible, melt it in a lifting furnace, heat it to a peak temperature of 900°C-1200°C, and melt it for 1-2 hours to make the melt compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com