High temperature resistant high speed wire drawing oil

A wire drawing oil and high temperature resistant technology, applied in the field of wire drawing oil, can solve the problems of difficulty in meeting the requirements of wire drawing and drawing process, unsatisfactory lubrication effect, difficulty in cleaning and chip removal, etc., and achieves excellent lubrication effect, storage resistance, Outstanding thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

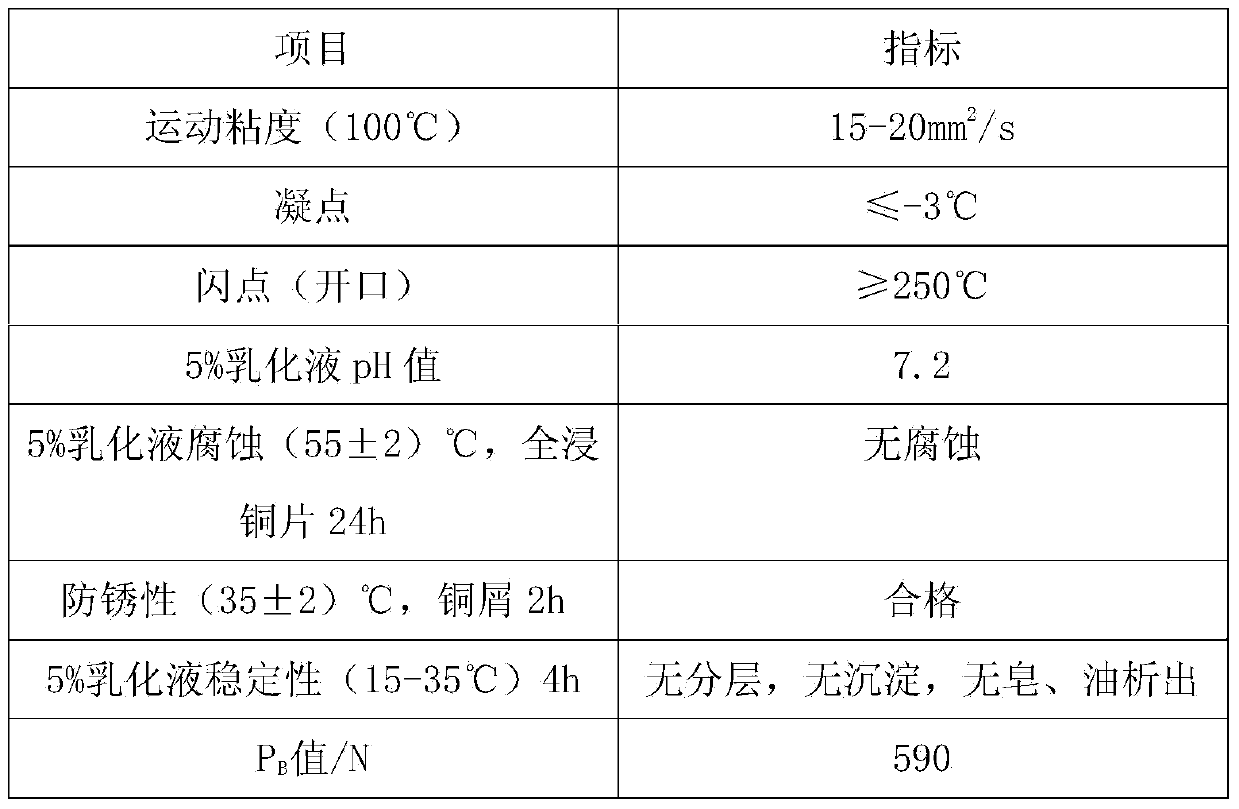

Image

Examples

Embodiment

[0010] The drawing oil in this embodiment is made from the following raw materials in parts by weight (kg): 2 stearic acid, 2-octyldodecanol 12, trimethylol propane 4, diisooctyl sebacate 80, hydrogenated poly 70 capene, 5 hydrogenated castor oil, 8 vulcanized cottonseed oil, 1 fatty acid methyl ester, 0.5 octylisothiazolinone, 1 butyl hydroxyanisole, and 3 auxiliary agents; the auxiliary agent is made of the following raw materials in parts by weight Ingredients: butyl stearate 15, graphene 1, sodium metasilicate 2, xanthan gum 10, lauryl polyoxyethylene ether 4, appropriate amount of deionized water; the preparation method is: first add butyl stearate Lauryl alcohol polyoxyethylene ether and graphene were stirred at 1500 rpm for 20 minutes to make an emulsion for later use, and then mixed xanthan gum with an appropriate amount of deionized water to prepare an aqueous solution of xanthan gum with a mass concentration of 70%. , and finally mix the aqueous solution, emulsion an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com