Method for treating cobalt nickel sulfate solution

A kind of technology of nickel cobalt sulfate and treatment method, which is applied in the metallurgical field to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

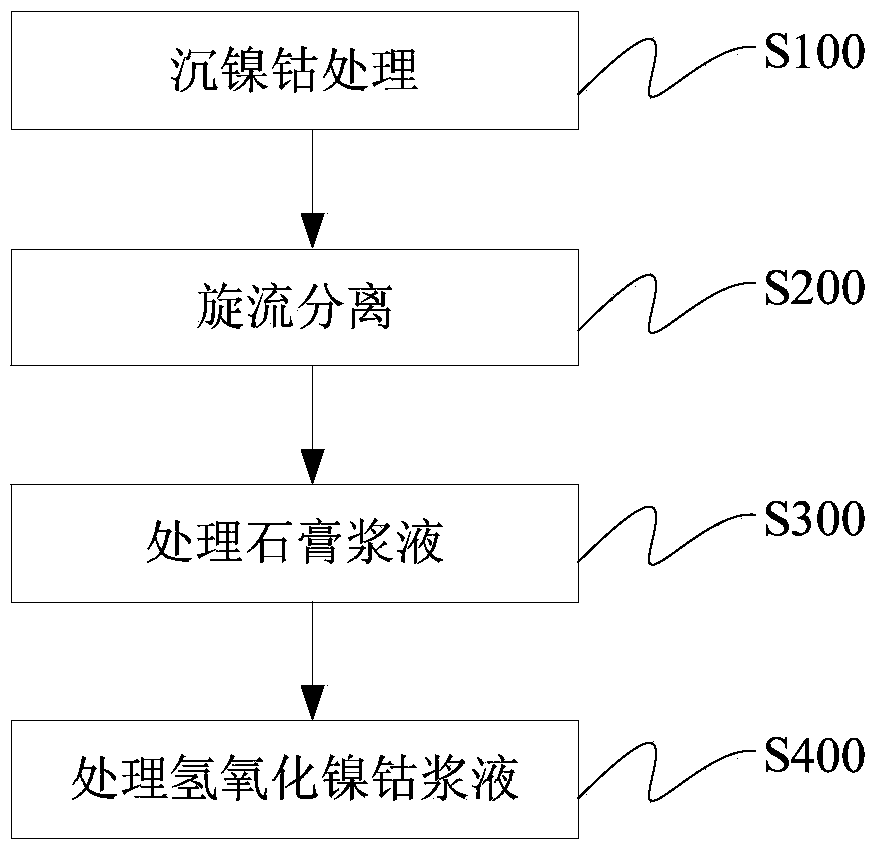

Method used

Image

Examples

Embodiment 1

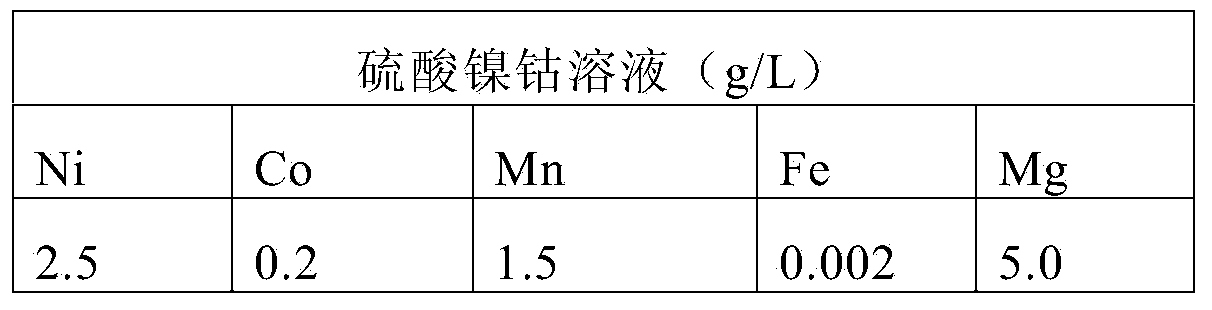

[0045] The composition of the nickel-cobalt sulfate solution to be treated is shown in Table 1;

[0046] Table 1

[0047]

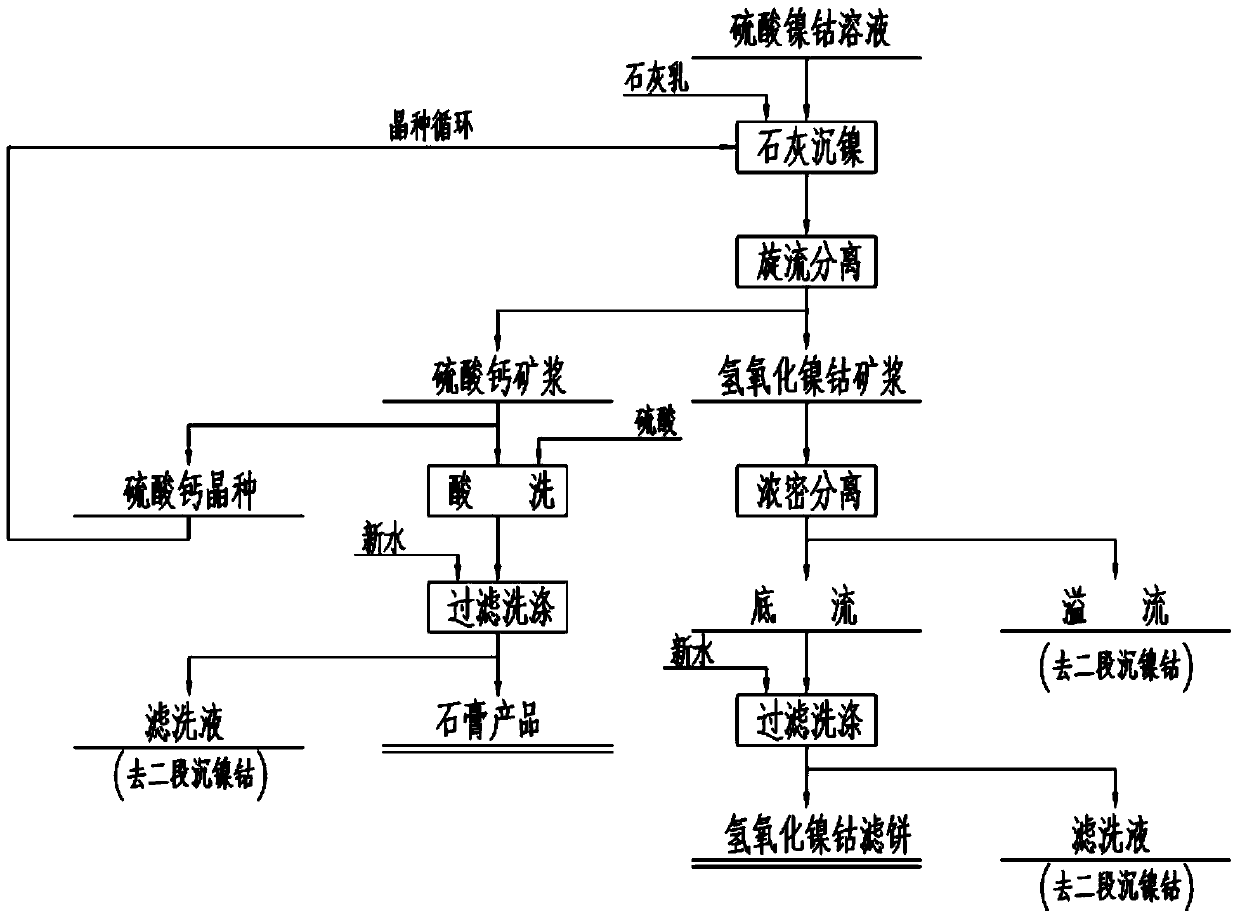

[0048] according to figure 2 Shown step, take above-mentioned nickel cobalt sulfate solution 5m 3 After being heated to 50 degrees Celsius, 340kg of milk of lime with a calcium hydroxide concentration of 5wt% was added thereto, and reacted for 1h. Separation is carried out by a cyclone. The overflow is nickel-cobalt hydroxide slurry, and the underflow is calcium sulfate slurry. Part of the calcium sulfate slurry is used as a seed crystal for precipitation. The gypsum seed crystal multiple is 8. Sulfuric acid and water with a concentration of 2wt% are used to pickle and filter the calcium sulfate slurry to obtain filtrate and gypsum products. The nickel-cobalt hydroxide slurry is densely separated to obtain an underflow slurry and an overflow slurry, and water is used to filter and wash the underflow slurry to obtain a nickel-cobalt hydroxide filter...

Embodiment 2

[0051] according to figure 2 Shown step, take above-mentioned nickel cobalt sulfate solution 5m 3 After being heated to 50 degrees Celsius, 170 kg of lime milk with a calcium hydroxide concentration of 10 wt % was added thereto, and reacted for 1 h. Separation is carried out by a cyclone, the overflow is nickel-cobalt hydroxide slurry, the underflow is calcium sulfate slurry, and a part of the calcium sulfate slurry is returned as a seed crystal for precipitation, and the gypsum seed crystal multiple is 5. Sulfuric acid and water with a concentration of 2wt% are used to pickle and filter the calcium sulfate slurry to obtain filtrate and gypsum products. The nickel-cobalt hydroxide slurry is densely separated to obtain an underflow slurry and an overflow slurry, and water is used to filter and wash the underflow slurry to obtain a nickel-cobalt hydroxide filter cake and a filtrate. Return the filtrate and overflow slurry obtained by the two-step filtration to carry out nicke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com