A kind of sealing method of aluminum alloy anodized film

An anodized film, aluminum alloy technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of limited film protection performance, film coloration, and high water quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with accompanying drawing, the present invention is to adopt the method for sealing anodic oxide film of aluminum alloy by ceramic coating, and this inventive process comprises following concrete steps:

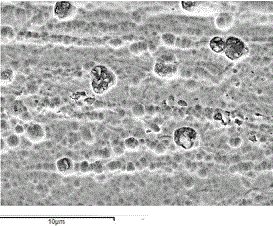

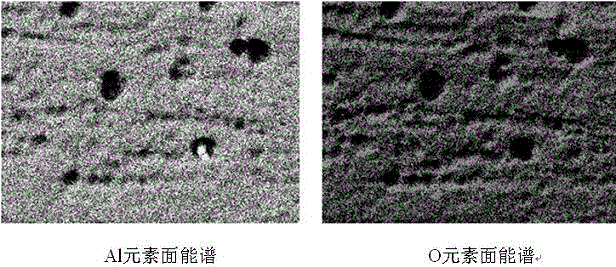

[0017] (1) Sample preparation, the 7475 alloy after anodic oxidation was selected as the sample for sealing treatment, and the sample size was 15mm×15mm×5mm; the surface morphology of the anodized film was observed by JSUPRA5 type field emission scanning electron microscope, as follows: figure 1 As shown, the energy spectrum analysis of the observation surface is as follows figure 2 shown. Depend on figure 1 , 2 It can be seen that there are obvious holes on the surface of the anodized film.

[0018] (2) Configure ceramic coating paint; 100g of Al 2 o 3 The powder is pre-mixed with 25g of sodium silicate binder, and ball milled together with 40ml of deionized water to form a coating. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com