Solar cell graphite boat and film coating method thereof

A technology of solar cells and graphite boats is applied in the field of building materials to achieve the effect of reducing the generation of chromatic aberration films, improving the uniformity of the coating and reducing the chromatic aberration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

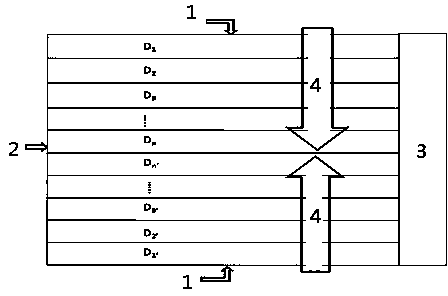

[0028] The distance between the blades of the conventional 19 graphite boats is 11mm. At this time, n=9, D1=D1'=D2=D2'=D3=D3'...=D9=D9'=11mm, and the voltage U applied between the blades At about 300V, the electric field intensity E between the boat blades is about 27.3kV / m, and the ability to excite plasma is the same. The diagram is attached figure 1 , denoted as graphite boat A.

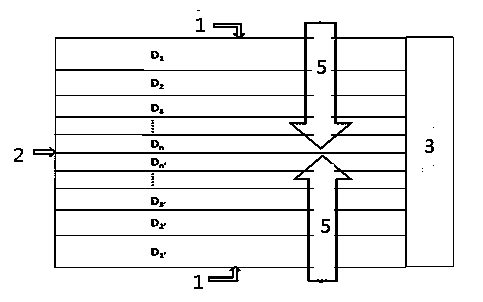

[0029] The embodiment of the present invention adopts the design of 19 graphite boats. At this time, n=9, and the distance between the boat blades from the outside of the graphite boat to the center is: D1=D1'=11.4mm, D2=D2'=11.3mm, D3=D3'= 11.2mm, D4=D4'=11.1mm, D5=D5'=11mm, D6=D6'=10.9mm, D7=D7'=10.8mm, D8=D8'=10.7mm, D9=D9'=10.6mm, At this time N=0.1mm. If the voltage U between the boat blades is kept constant at 300V, the electric field strength corresponding to the boat blade spacing is: E1=E1'=26.3kV / m, E2=E2'=26.5kV / m, E3=E3' =26.8kV / m, E4=E4'=27.0kV / m, E5=E5'=27.3kV / m, E6=E6'=27.5kV / m...

Embodiment 2

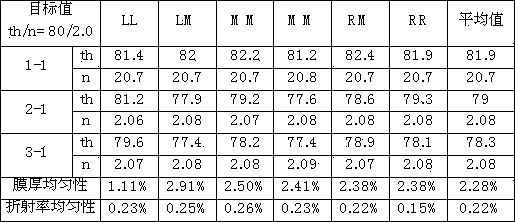

[0032] Use the same coating process to coat the graphite boat A and graphite boat B in Example 1 respectively. The single crystal silicon wafers used come from the same silicon ingot and are processed through the same conventional process: primary cleaning, diffusion and secondary Cleaning and film preparation go through the following steps: entering the boat, cleaning, purging, leak testing, pre-deposition, film deposition, purging, and exiting the boat. The process conditions of the pre-cleaning step are: temperature 450°C, nitrogen flow rate 2L / min, ammonia flow rate 6L / min, pressure 1.6Torr, radio frequency power 4.8kW, radio frequency switching time ratio Ton:Toff=4ms:48ms, duration 200s; the first pre-deposition process conditions are: temperature 450°C, nitrous oxide flow rate 6L / min, silane flow rate 0.8L / min, pressure 1.6Torr, duration 20s; the first layer thin film deposition process conditions are: temperature 450°C, nitrous oxide flow rate 6L / min, silane flow rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com