Ionic liquid catalyst and preparing method of ionic liquid catalyst

A technology of ionic liquid and catalyst, which is applied in the field of new catalytic materials and its preparation, can solve problems such as high energy consumption, and achieve the effects of simple equipment, simple preparation method and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

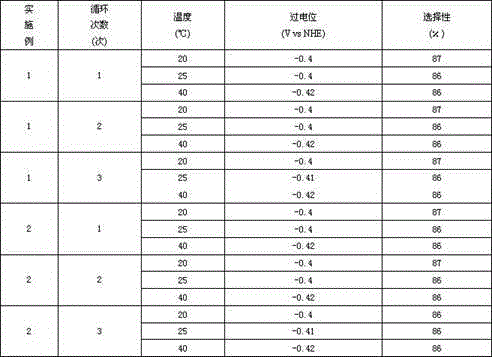

Examples

Embodiment 1

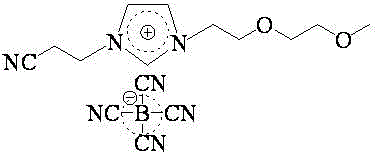

[0017] (1) Add 1.2 moles of 1-cyanoethylimidazole and 1.0 moles of 2-chlorodiethylene glycol methyl ether into the reaction kettle, stir at room temperature for 30 minutes, fully mix the raw materials, and raise the temperature to 80°C at a rate of 10°C / min , stirred and reacted at a constant temperature of 80°C for 24 hours, cooled to room temperature, extracted three times with an equal volume of cyclohexane to remove excess 1-cyanoethylimidazole and unreacted 2-chlorodiethylene glycol methyl ether, and further heated at 60°C Vacuum drying for 24 hours gave the intermediate product 1-cyanoethyl-3-(3,6-dioxoheptyl)imidazolium chloride salt;

[0018] (2) Add 1.0 moles of 1-cyanoethyl-3-(3,6-dioxoheptyl) imidazolium chloride salt, 1.5 moles of potassium tetracyanoborate and an equal volume of anhydrous acetone into the reaction kettle, and stir at 25°C React for 48 hours, stop the reaction, filter to remove potassium chloride and excess potassium tetracyanoborate, and vacuum-dr...

Embodiment 2

[0020] (1) Add 1.2 moles of 1-cyanoethylimidazole and 1.0 moles of 2-chlorodiethylene glycol methyl ether into the reaction kettle, stir at room temperature for 30 minutes, fully mix the raw materials, and raise the temperature to 80°C at a rate of 10°C / min , stirred and reacted at a constant temperature of 80°C for 36 hours, lowered to room temperature, extracted 4 times with an equal volume of cyclohexane to remove excess 1-cyanoethylimidazole and unreacted 2-chlorodiethylene glycol methyl ether, and further heated at 60°C Vacuum drying for 24 hours gave the intermediate product 1-cyanoethyl-3-(3,6-dioxoheptyl)imidazolium chloride salt;

[0021] (2) Add 1.0 moles of 1-cyanoethyl-3-(3,6-dioxoheptyl) imidazolium chloride salt, 1.5 moles of potassium tetracyanoborate and an equal volume of anhydrous acetone into the reaction kettle, and stir at 25°C React for 48 hours, stop the reaction, filter to remove potassium chloride and excess potassium tetracyanoborate, and vacuum-dry t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com