ZrC-ZrO2 composite ceramic microsphere and preparation method thereof

A technology of composite ceramics and microspheres, which is applied in the field of ZrC-ZrO2 composite ceramic microspheres and its preparation, can solve the problems of high reaction temperature, few reports on the preparation of ZrC small-sized microspheres, and few reports on the methods of composite ceramic microspheres. Achieve the effect of simplifying the production process, uniform size and good sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

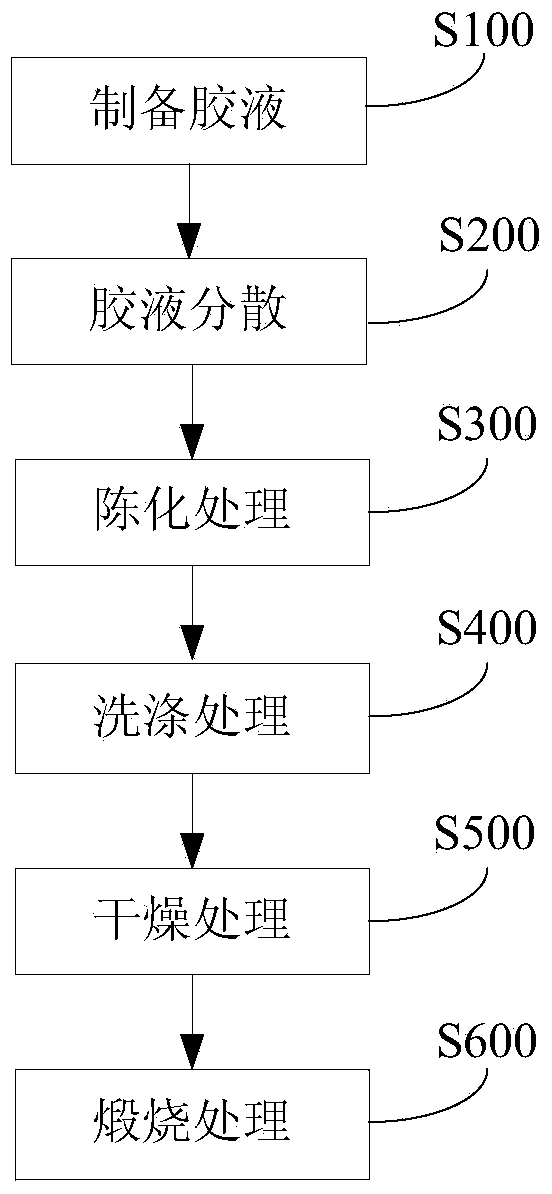

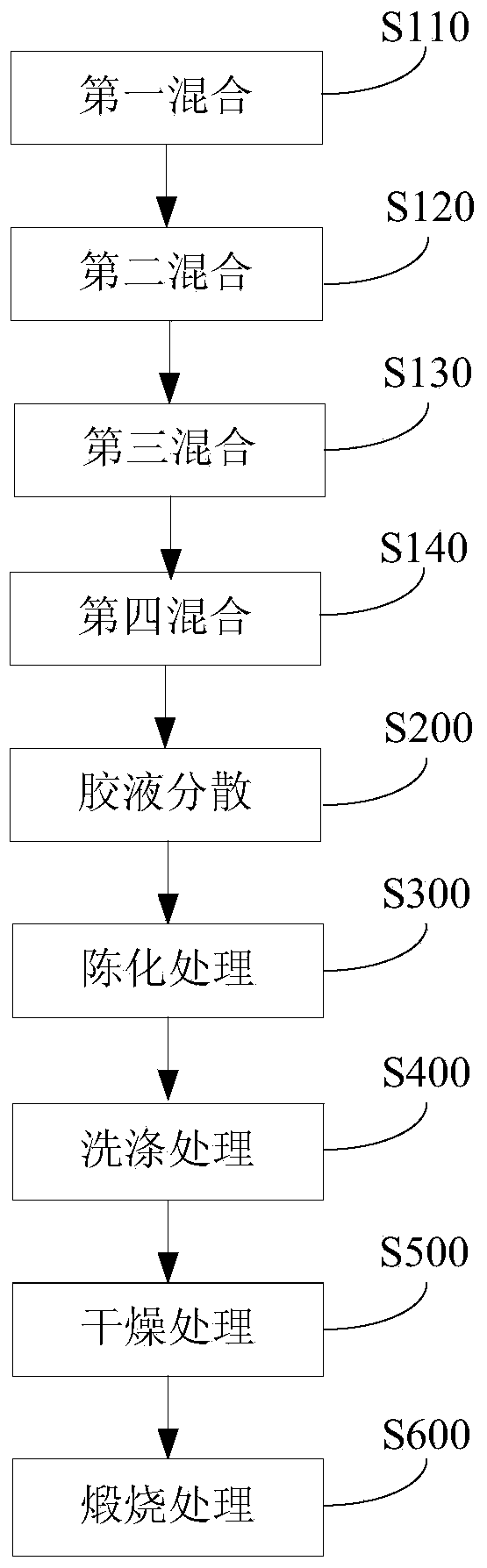

Method used

Image

Examples

preparation example Construction

[0060] According to the preparation ZrC-ZrO of the embodiment of the present invention 2 The method of composite ceramic microspheres can effectively prepare ZrC-ZrO with uniform and controllable size, good sphericity and no cracks. 2 Composite ceramic microspheres, and the resulting composite microspheres combine ZrC and ZrO 2 The advantages of both, solve the ZrO 2 The disadvantage of poor thermal conductivity broadens the ZrO 2 It provides a material for the selection of reactor inert matrix materials and other application fields. At the same time, the preparation of zirconium carbide powder and the formation of spheres are carried out in one step, which simplifies the production process. In the ball washing stage of the process, the high-temperature and high-pressure washing balls of the reactor and the propylene glycol methyl ether washing balls are used to quickly remove impurities and moisture in the balls, which greatly shortens the drying time of the balls and slows...

Embodiment

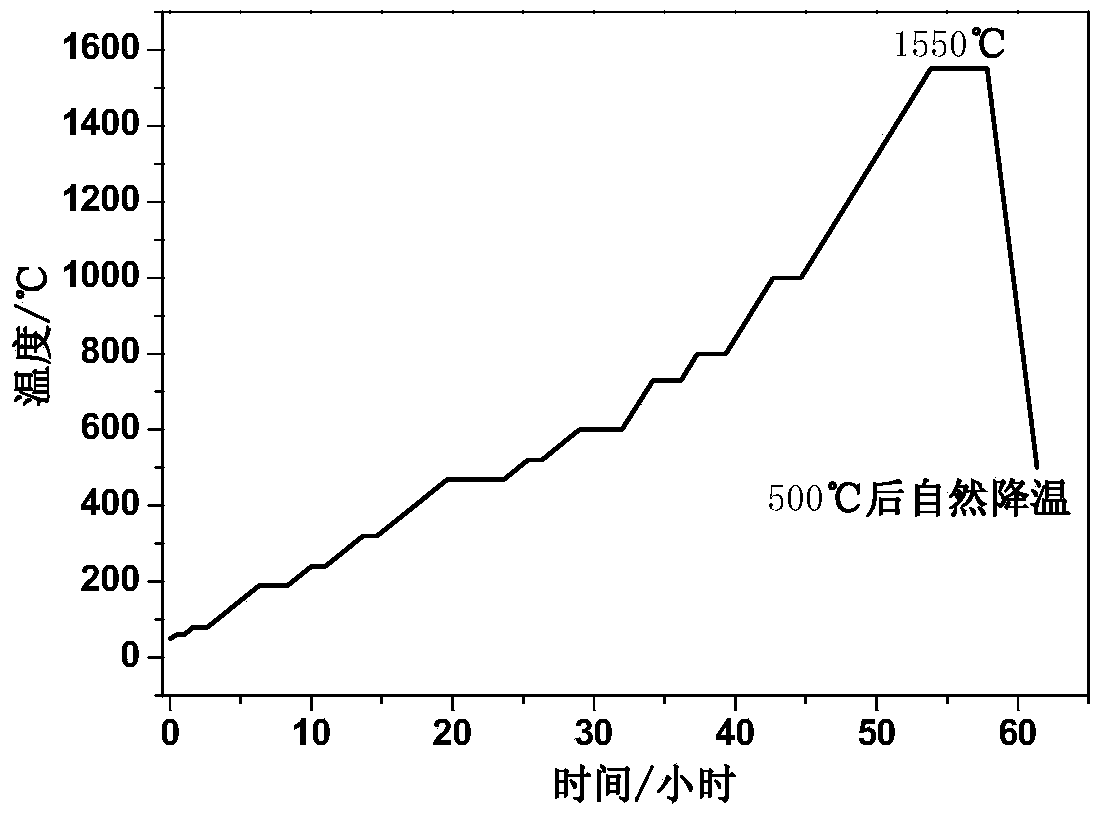

[0064] Prepare a mixed solution containing 3mol / L hexamethylenetetramine (HMTA) and 2.625mol / L urea (Urea) while cooling to 4°C, add carbon powder to the mixed solution and add Triton 100 and weight Nitrogen salts make the dispersion of carbon powder in the mixed solution uniform and stable; dissolve ZrO(NO 3 ) 2 and Y(NO 3 ) 3 , and configure ZrO(NO 3 ) 2 and 0.14mol / L of Y(NO 3 ) 3 Cool the prepared mixed solution to 4°C; let the above two solutions stand at 4°C for at least 1h, then add the HMTA / Urea solution to the Zr / Y solution, and add HNO at the same time 3 Adjust the pH value to about 1.3, and measure the pH value immediately after the glue is mixed evenly. The prepared glue is stored at 4°C for 1 hour and then used for gelation and dispersion. The concentration of metal ions in the final glue solution is about 0.8-1.1mol / L, the molar ratio of HMTA to metal ions is 1.1-1.3, the molar ratio of urea to metal ions is 0.96-1.14, and the pH value is between 1-2. Bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com