A kind of preparation method of phase change microcapsule/uhmwpe wear-resistant material

A technology of phase-change microcapsules and wear-resistant materials, which is applied in the field of composite wear-resistant materials, can solve problems such as high friction coefficient and low wear rate, and achieve the effects of improving wear resistance, maintaining continuity, and reducing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of phase change microcapsule / UHMWPE wear-resistant material, comprising the following steps:

[0025] Step 1, the preparation of microcapsule powder

[0026] (1) Mix formaldehyde solution with a molar ratio of 3.6:1 and melamine, add an appropriate amount of distilled water to form a mixed solution, and stir the mixed solution in a constant temperature water bath at 70°C until the system is transparent, wherein the mass percent concentration of the formaldehyde solution is 37 %, then add a NaOH solution with a mass percentage concentration of 10% to adjust the pH of the system to 10, and the temperature of the water bath is lowered to 40°C and continued to stir for 30 minutes to obtain a formaldehyde-melamine prepolymer;

[0027] (2) According to the weight ratio of formaldehyde-melamine prepolymer and paraffin prepared in step (1) to 1.5:1, weigh the paraffin with a phase transition temperature of 48~50°C, and add 37.6% of the weight of the weighed...

Embodiment 2

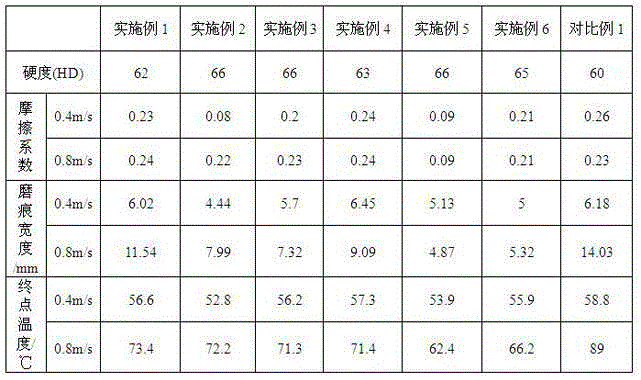

[0035] Prepare microcapsule powder according to the preparation method of step 1 in Example 1, and then weigh 80% of the UHMWPE powder and 20% of the microcapsule powder prepared in step 1 according to the weight percentage, and then carry out step 2 to step 6 in Example 1 steps, the test results are as follows figure 1 shown.

Embodiment 3

[0037] Prepare microcapsule powder according to the preparation method of step 1 in Example 1, and then weigh 70% of the UHMWPE powder and 30% of the microcapsule powder prepared in step 1 according to the weight percentage, and carry out step 2 to step 6 in Example 1 in sequence steps, the test results are as follows figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com