Power generation technology with biogas produced by mixed fermentation of excrement and straws of distributed swine breeder

A technology of mixed fermentation and biogas power generation, applied in fermentation, biological sludge treatment, waste fuel, etc., can solve the problems of insufficient use of biogas, low biogas rate, and thin manure concentration, and achieve resource utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

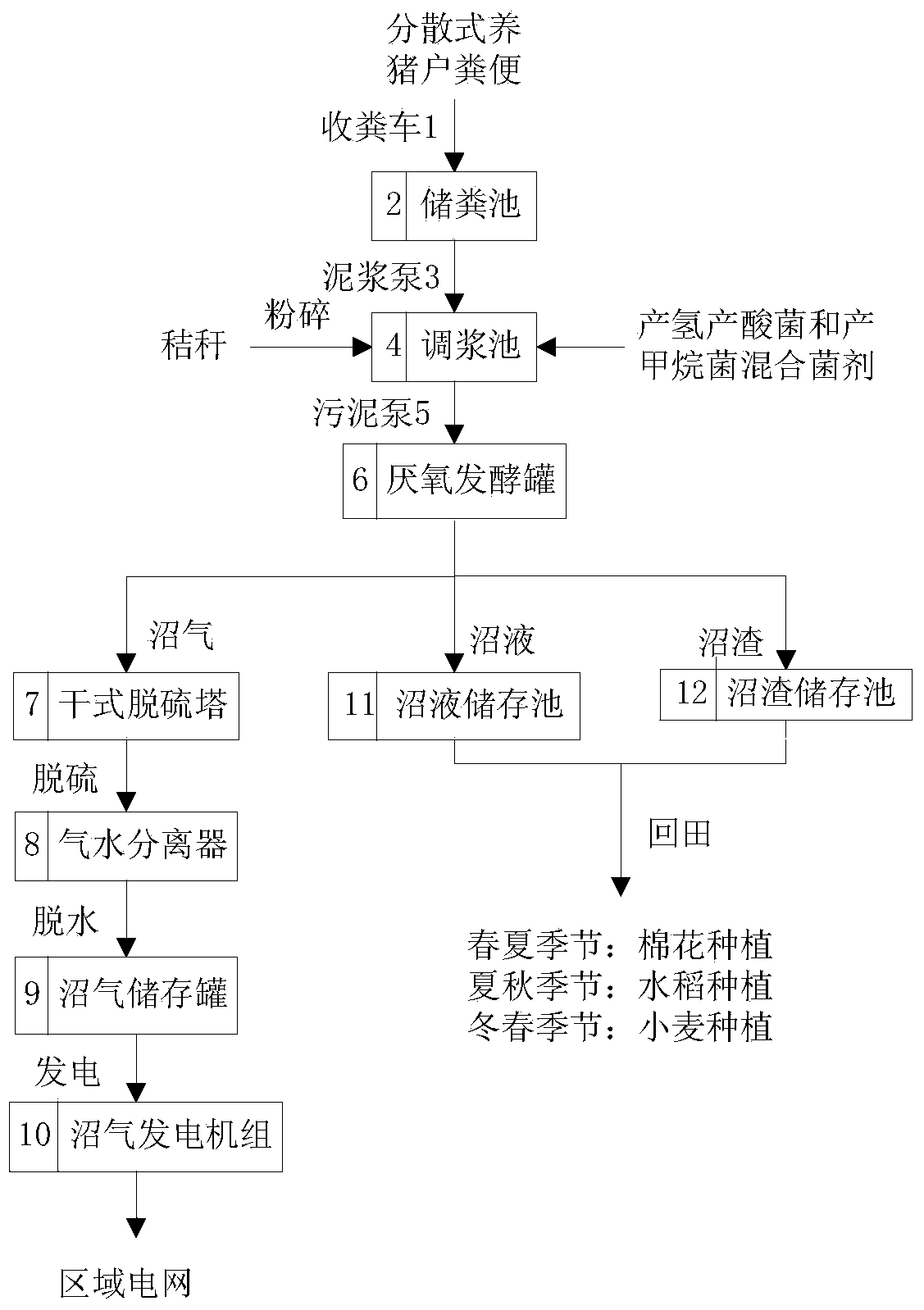

Method used

Image

Examples

Embodiment 1

[0029] The excrement of decentralized pig farmers is collected by a manure collection truck and transported to the manure storage tank. When the collected amount reaches 25t, it is pumped to the slurry mixing tank by a mud pump, and then 0.8t of rice straw is crushed and mixed with 2.5kg of commercial hydrogen production. Add the mixed bacterial agent of acid bacteria and methanogens to 25t of distributed pig farmer manure, stir it evenly with a mixer, and then use a sludge pump to pump it into an anaerobic fermentation tank for anaerobic fermentation. The effective volume of the anaerobic fermentation tank is 300m 3 , treated by microbial anaerobic fermentation, the biogas produced is treated by dry desulfurization tower and gas-water separator, and then stored in biogas storage tank, with an output of 760m 3 . The biogas can be used to generate electricity by biogas generator set, which can generate 1292KWh.

Embodiment 2-5

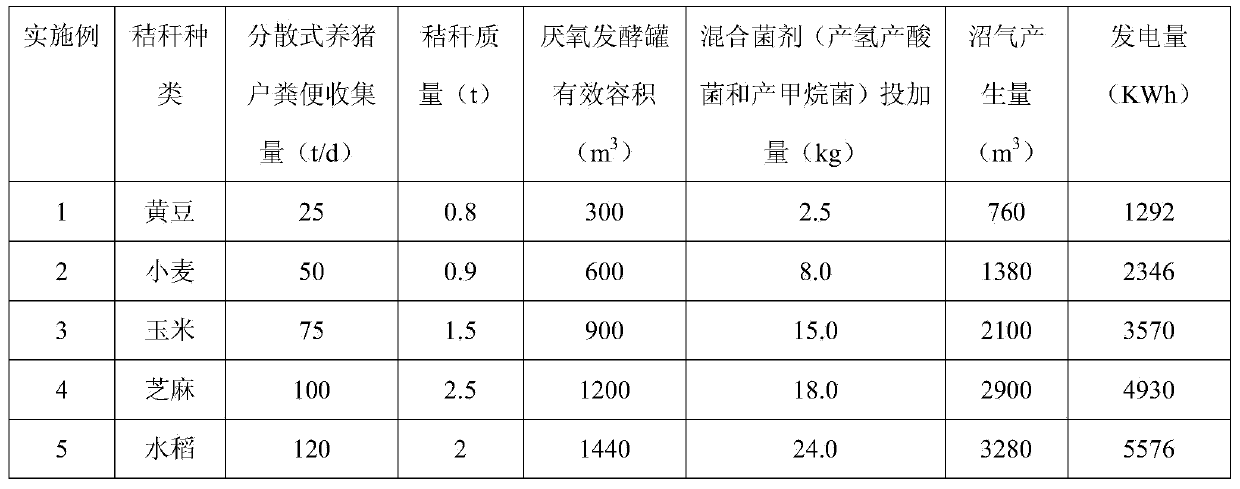

[0031] The difference between embodiment 2-5 and embodiment 1 is that the excrement collection amount of the raw material dispersed pig farmers is different, the types of crop stalks used are different (wheat, corn, sesame, rice), the effective volume of the anaerobic fermentation tank is different, and the mixed bacterial agent ( Hydrogen-producing acid-producing bacteria and methanogenic bacteria) have different dosages, and other process parameters and treatment methods are the same. Table 1 shows five examples of decentralized pig farmer manure and straw mixed fermentation biogas power generation technology.

[0032] Table 1 Example of biogas power generation technology using decentralized mixed fermentation of pig farmer manure and straw

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com