Raw material pre-wetting stirring machine with quantitative smashing function and using method of raw material pre-wetting stirring machine with quantitative smashing function

A technology of mixer and mixing mechanism, which is applied to mixers with rotating mixing devices, mixer accessories, chemical instruments and methods, etc., can solve the problems of unstable quality, uneven mixing, backward automation, etc., to reduce labor intensity of workers, Thorough and uniform mixing, resulting in improved automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

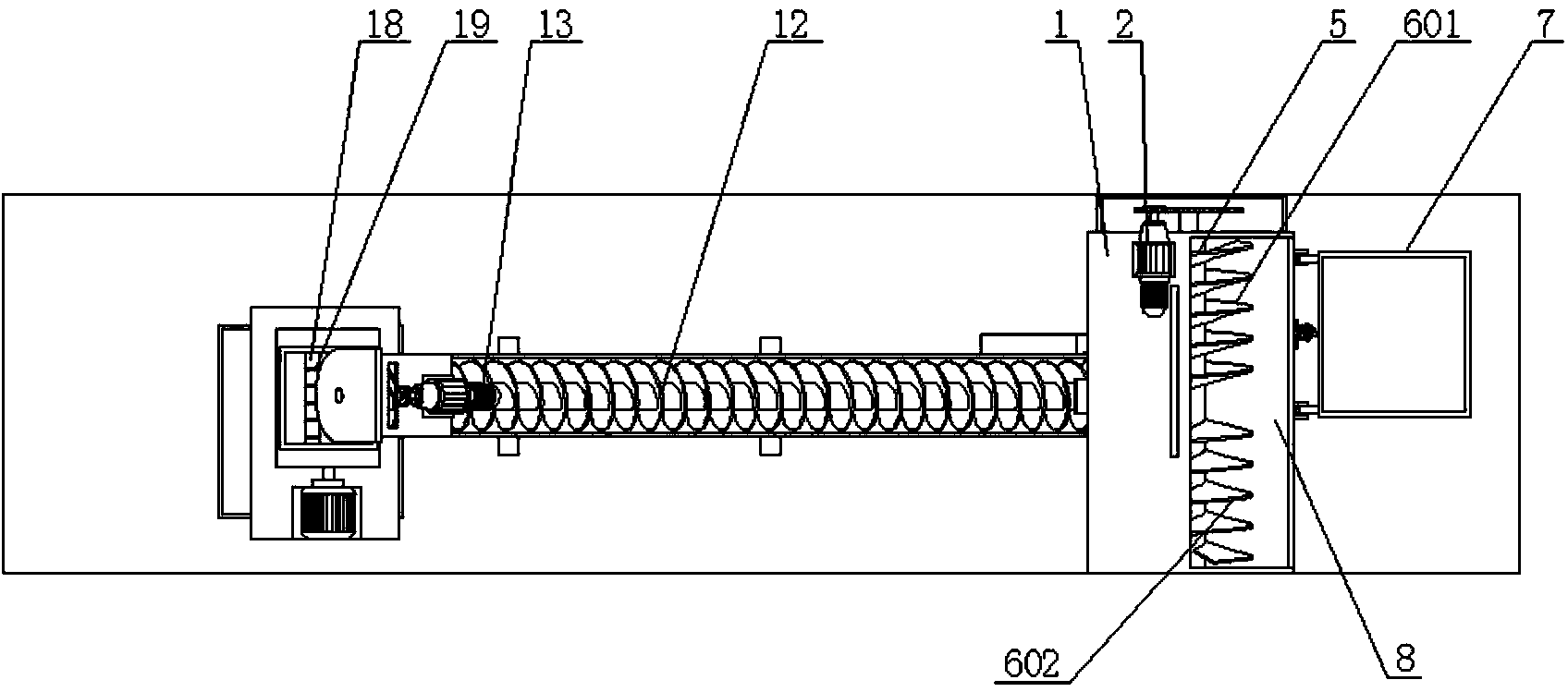

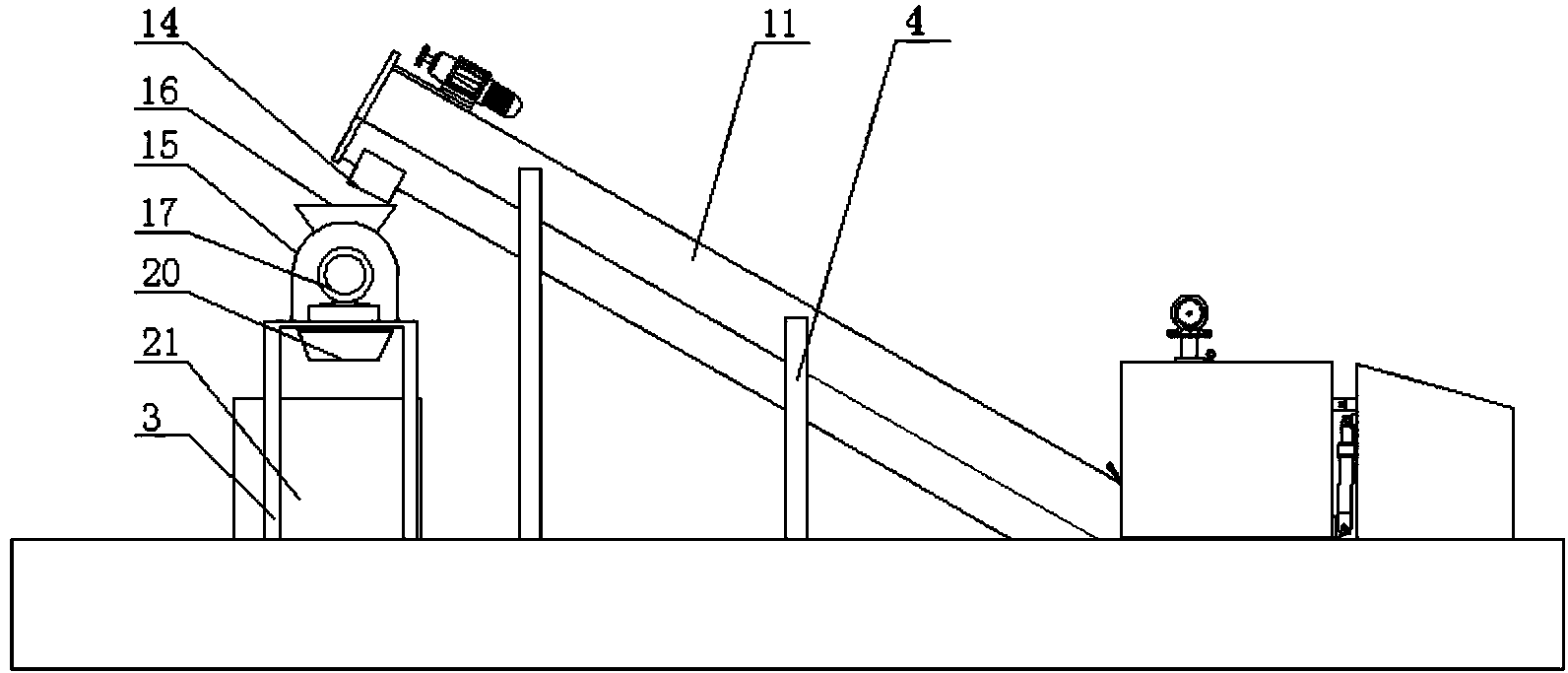

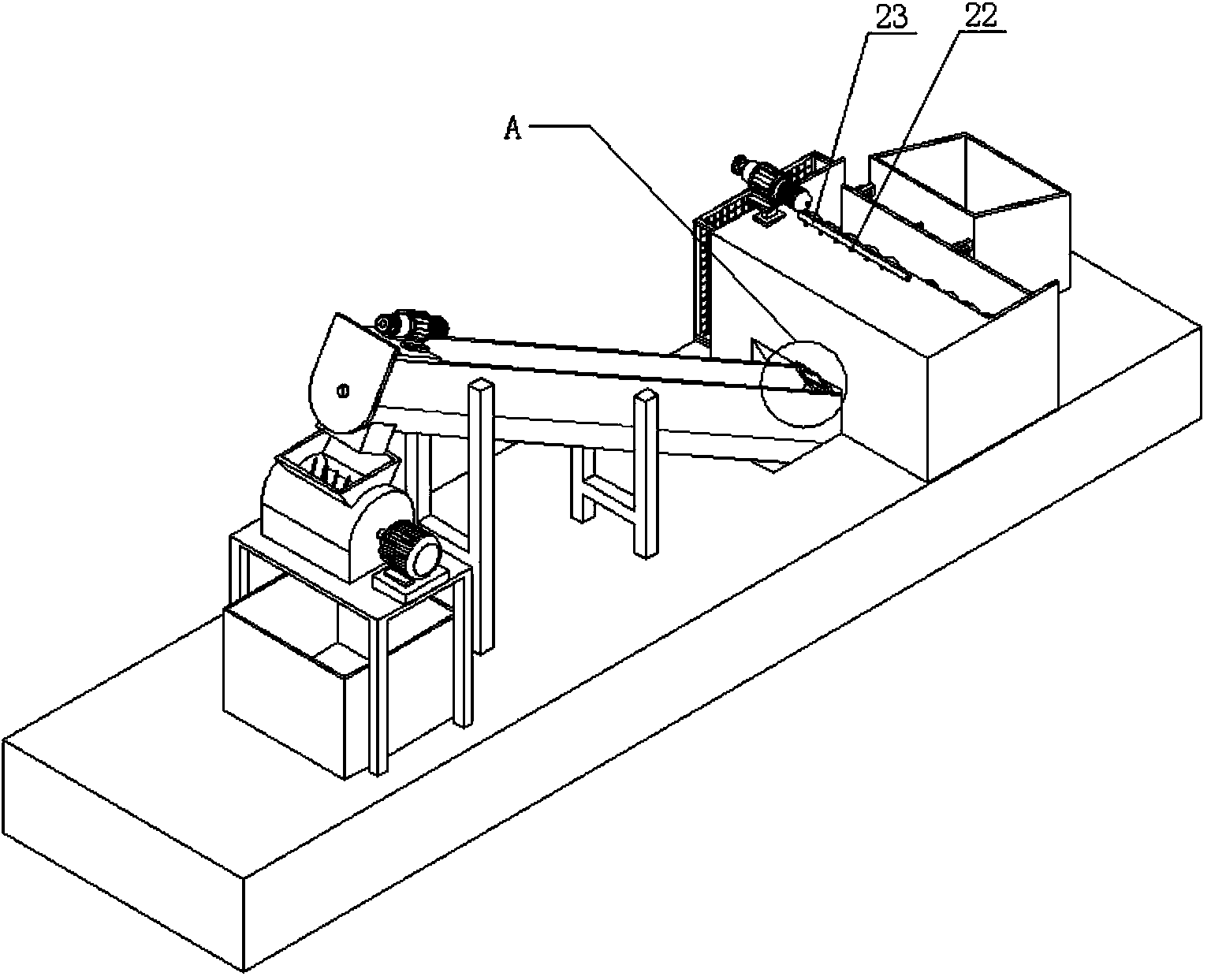

[0032] Such as Figure 1 to Figure 5As shown, a raw material pre-wet mixer with quantitative crushing function includes a stirring mechanism, a conveying mechanism and a crushing mechanism arranged in sequence along the raw material conveying direction, wherein: the stirring mechanism includes a mixing box 1 with a semi-closed top, which is far away from the conveying mechanism. The top opening on one side of the mechanism forms the first feeding port 8, and the side box wall is connected to a feeding cylinder 7 through a rotating cylinder. There is a rotating shaft 5 perpendicular to the conveying direction of the raw materials, and the outer surface of the rotating shaft 5 is surrounded by several circles of spiral mixing blades along its length direction. It is a counter-rotating spiral mixing blade 602, the rotating shaft 5 is parallel to the motor rotating shaft on the first reduction motor 2 and is connected through a gear set outside the box;

[0033] A main water pipe...

Embodiment 2

[0045] Such as Figure 1 to Figure 5 As shown, a raw material pre-wet mixer with quantitative crushing function includes a stirring mechanism, a conveying mechanism and a crushing mechanism arranged in sequence along the raw material conveying direction, wherein: the stirring mechanism includes a mixing box 1 with a semi-closed top, which is far away from the conveying mechanism. The top opening on one side of the mechanism forms the first feeding port 8, and the side box wall is connected to a feeding cylinder 7 through a rotating cylinder. There is a rotating shaft 5 perpendicular to the conveying direction of the raw materials, and the outer surface of the rotating shaft 5 is surrounded by several circles of spiral mixing blades along its length direction. It is a counter-rotating spiral mixing blade 602, the rotating shaft 5 is parallel to the motor rotating shaft on the first reduction motor 2 and is connected through a gear set outside the box;

[0046] Two main water p...

Embodiment 3

[0058] Such as Figure 1 to Figure 5 As shown, a raw material pre-wet mixer with quantitative crushing function includes a stirring mechanism, a conveying mechanism and a crushing mechanism arranged in sequence along the raw material conveying direction, wherein: the stirring mechanism includes a mixing box 1 with a semi-closed top, which is far away from the conveying mechanism. The top opening on one side of the mechanism forms the first feeding port 8, and the side box wall is connected to a feeding cylinder 7 through a rotating cylinder. There is a rotating shaft 5 perpendicular to the conveying direction of the raw materials, and the outer surface of the rotating shaft 5 is surrounded by several circles of spiral mixing blades along its length direction. It is a counter-rotating spiral mixing blade 602, the rotating shaft 5 is parallel to the motor rotating shaft on the first reduction motor 2 and is connected through a gear set outside the box;

[0059] A main water pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com