Dispersible oil suspension agent for low-melting-point compound and preparation method thereof

A compound and low melting point technology, applied in botany equipment and methods, biocides, animal repellents, etc., can solve the problems of difficult product particle size distribution, low production efficiency, solid precipitation, etc., and achieve physical stability Good, saving production cost, stable physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

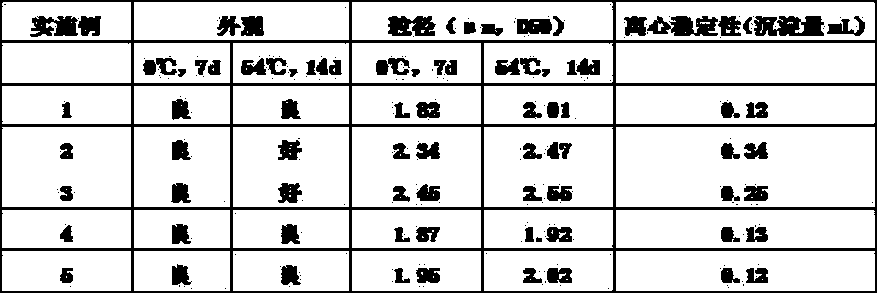

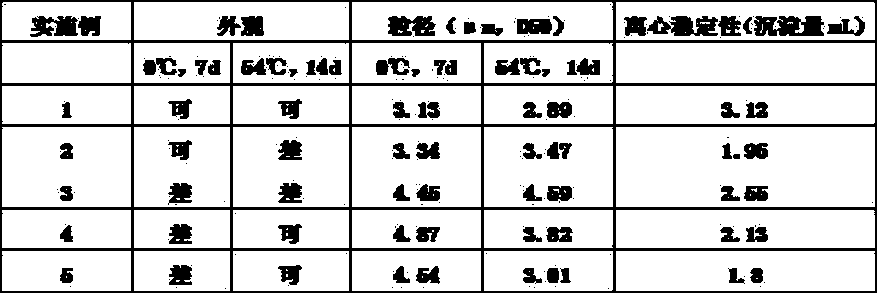

Examples

Embodiment 1

[0018] Embodiment 1: prepare 5% clodinafop-propargyl dispersible oil suspension concentrate

[0019] The mass percent of each component is as follows:

[0020] Clodinafop-propargyl technical (calculated by 100 percent) 5%

[0021] Castor oil polyoxyethylene ether (BY-140) 4%

[0022] Calcium dodecylbenzenesulfonate (Nongru 500#) 6%

[0023] Sodium lignosulfonate (Reax 82p) 1.5%

[0024] High molecular carboxylic acid polymer TERSPERSE 2700 1.5%

[0025] Fumed silica 1%

[0026] Organic bentonite 2%

[0027] Methyl caprylate 20%

[0028] Methylated soybean oil balance

[0029] Preparation:

[0030] Mix clodinafop-propargyl with methyl caprylate and methylated soybean oil, heat it up to 70°C by electric heating, stir while heating, and add emulsifier BY-140 and agricultural Milk 500#, stir evenly. Then add TERSPERSE 2700, Reax 82p, fumed silica, and organic bentonite to it, and stir again to obtain 5% clodinafop-propargyl dispersible oil suspension concentrate.

Embodiment 2

[0031] Embodiment 2: prepare 15% cyhalofop-methyl dispersible oil suspension concentrate

[0032] Cyhalofop-ethyl technical (calculated by 100% discount) 15%

[0033] Castor oil polyoxyethylene ether (BY-140) 7%

[0034] Calcium dodecylbenzenesulfonate (Nongru 500#) 8%

[0035] Sodium lignosulfonate (Reax 82p) 1.5%

[0036] High molecular carboxylic acid polymer (Tersperse 2500) 3.5%

[0037] Organic bentonite 3%

[0038] Methyl caprylate 18%

[0039] Methylated corn oil balance

[0040] Preparation:

[0041] Mix cyhalofop-ethyl with methyl caprylate and methylated corn oil, heat it up to 50°C by electric heating, stir while heating, and add BY-140 and agricultural milk after it is completely melted 500#, stir evenly. Then add Reax 82p, Tersperse 2500 and organic bentonite to it and stir evenly again to obtain 15% cyhalofop-ethyl dispersible oil suspension concentrate.

Embodiment 3

[0042] Embodiment 3: Preparation of 25% fluroxazone dispersible oil suspension concentrate

[0043] Fluoxetalone technical (calculated by 100% discount) 25%

[0044] EO-PO block copolymer (Pluronic F108) 10%

[0045] Fatty alcohol ethoxylate (Emulan AF) 10%

[0046] Naphthalenesulfonate Dispersant (NNO) 3%

[0047] High molecular carboxylic acid polymer TERSPERSE 2700 1%

[0048] Fumed silica 1%

[0049] Magnesium Aluminum Silicate 1.5%

[0050] Methyl caprylate 15%

[0051] Methylated soybean oil balance

[0052]Mix fentrazone with methyl caprylate and methyl soybean oil, heat it up to 50°C by electric heating, stir while heating, and add Pluronic F108 and Emulan AF after it is completely melted, and stir evenly . Then add TERSPERSE 2700, magnesium aluminum silicate, and fumed silica to it and stir evenly again to obtain 25% fluroxazone dispersible oil suspension concentrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com