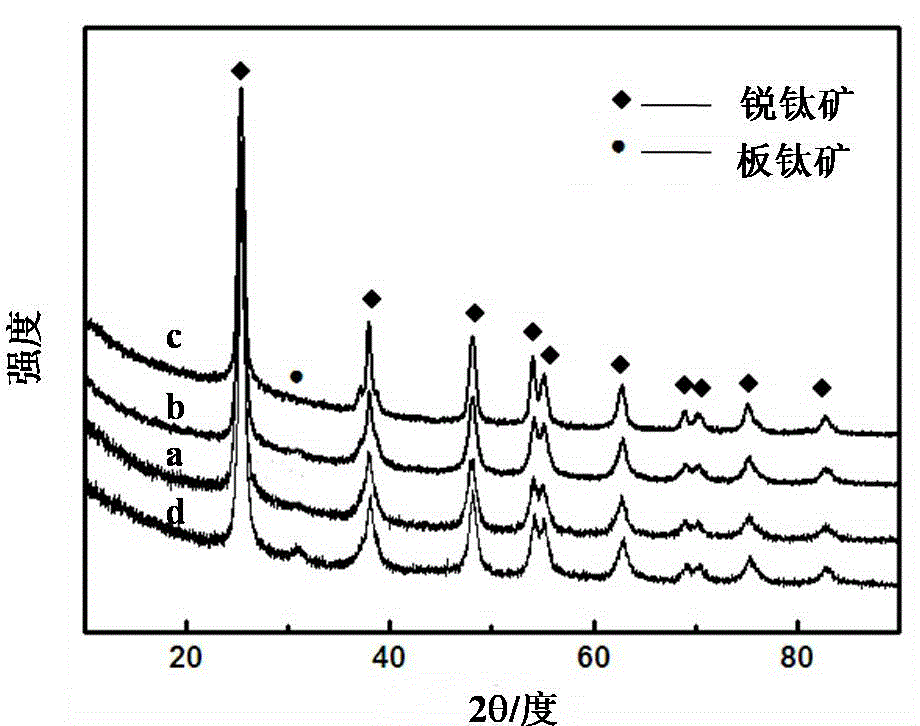

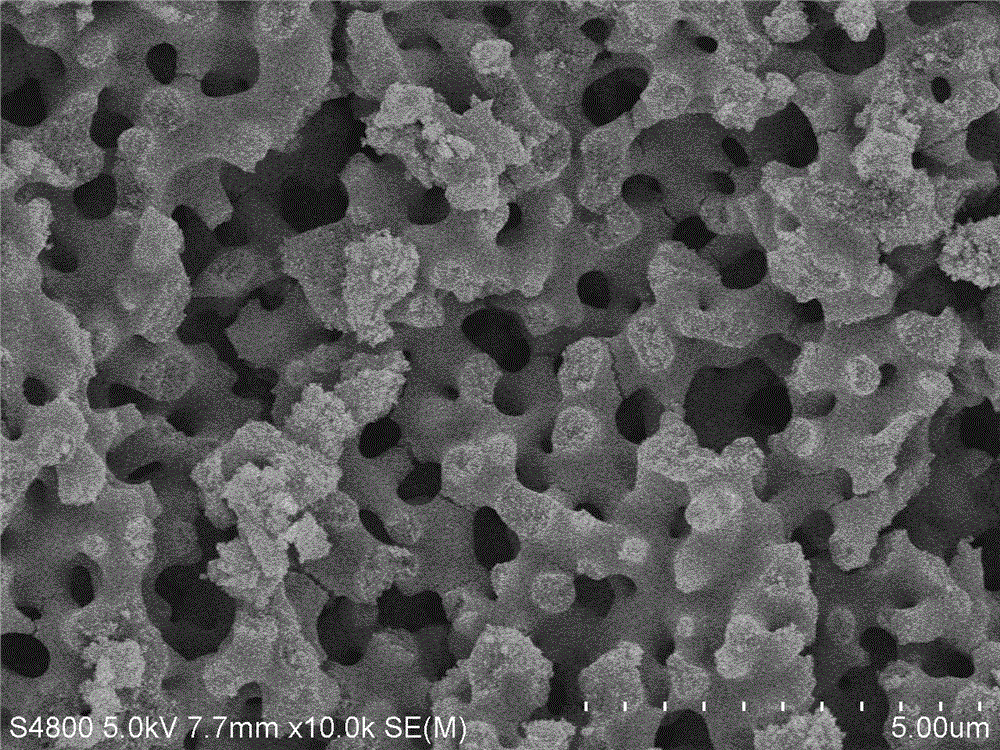

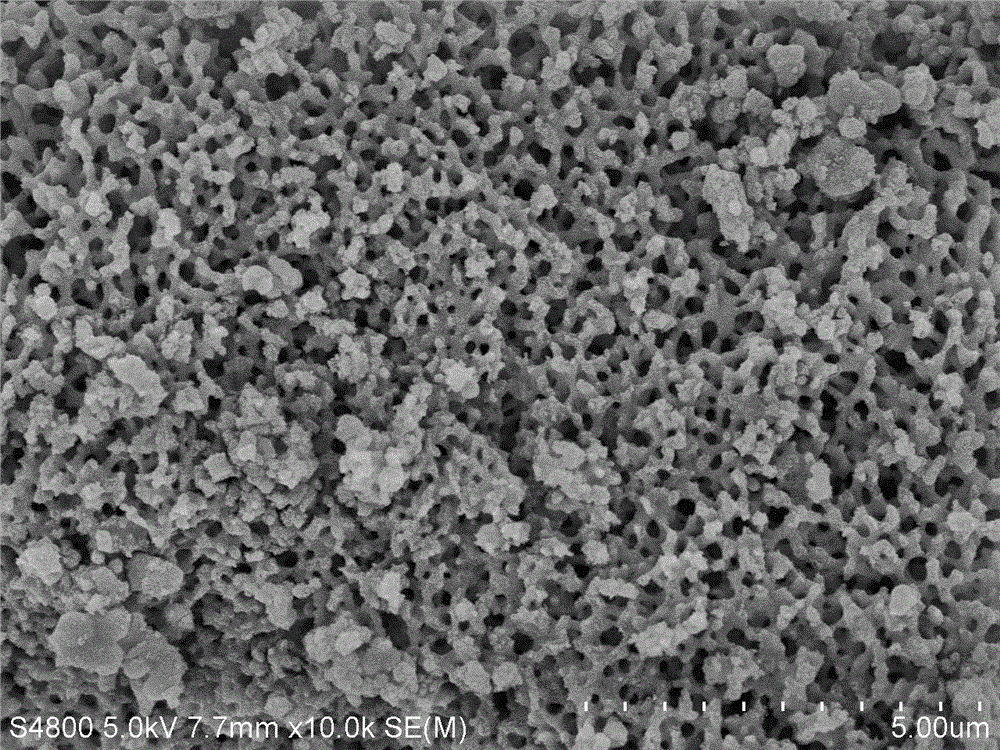

Preparation method for nitrogen-doped TiO2 (titanium dioxide) powder of reticulated porous structure

A reticular porous, titanium dioxide technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as lack of crystallinity, low specific surface area, and improved visible light activity, and achieve low cost. , Simple operation, widely distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Extraction of nitrogen source: select freshwater mussels with a shell age of 5 years and wash them. Use a scalpel to incise the closure muscles on both sides of the shell, place the shell upside down on a clean tray for 10 minutes, and allow the water in the shell to fully drain. Gently tear off the mantle in the shell, and quickly draw the mantle liquid into the centrifuge tube with a pipette gun. The extracted mantle fluid was stored at -70°C.

[0039] (2) Preparation of precipitation mixture: 25 ml of mantle solution with a protein concentration of 1250 mg / ml was added dropwise to 5 ml of tetrabutyl titanate, and fully stirred for 1 h (rotation speed: 800 r / min). A precipitation mixture of white precipitate and mantle solution was obtained.

[0040] (3) Mineralization at room temperature: put the obtained precipitation mixture at room temperature for 12 h to allow the mantle solution to fully interact with the white precipitate to obtain TiO 2 precipitation mi...

Embodiment 2

[0047] (1) Extraction of nitrogen source: select freshwater mussels with a shell age of 3 years and wash them. Use a scalpel to incise the closing muscles on both sides of the shell, and place the shell upside down on a clean tray for 20 minutes to allow the water in the shell to fully drain. Gently tear off the mantle in the shell, and quickly draw the mantle liquid into the centrifuge tube with a pipette gun. The extracted mantle fluid was stored at -70°C.

[0048] (2) Preparation of precipitation mixture: 5 ml of mantle solution with a protein concentration of 800 mg / ml was added dropwise to 0.5 ml of tetrabutyl titanate, and fully stirred for 2 h (rotating speed at 1000 r / min). A precipitation mixture of white precipitate and mantle solution was obtained.

[0049] (3) Mineralization at room temperature: Put the obtained precipitation mixture at room temperature for 18 h to allow the mantle solution to fully interact with the white precipitate to obtain TiO 2 precipitati...

Embodiment 3

[0054] (1) Extraction of nitrogen source: Select freshwater mussels with a shell age of 6 years and wash them. Place the shells upside down in the cleaned tray for 15 minutes to allow the water in the shells to fully drain. Use a scalpel to incise the obturator muscles on both sides of the shell, gently tear off the mantle in the shell, and use a pipette to quickly absorb the mantle liquid into the antifreeze centrifuge tube. The extracted mantle fluid was stored at -70°C.

[0055] (2) Preparation of precipitation mixture: 14 ml of mantle solution with a protein concentration of 400 mg / ml was added dropwise to 2 ml of tetrabutyl titanate, and fully stirred for 2 h (1200 r / min), A precipitation mixture of white precipitate and mantle solution was obtained.

[0056] (3) Mineralization at room temperature: Put the obtained precipitation mixture at room temperature for 24 h to allow the mantle solution to fully interact with the white precipitate to obtain TiO 2 precipitation m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com