Antibacterial coating and preparation method thereof

An antibacterial paint and antibacterial agent technology, applied in the field of antibacterial paint and its preparation, can solve the problems of insufficient stability of nano silver, destroy paint resin, reduce paint life, etc., achieve good compatibility, improve conversion rate, and improve compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

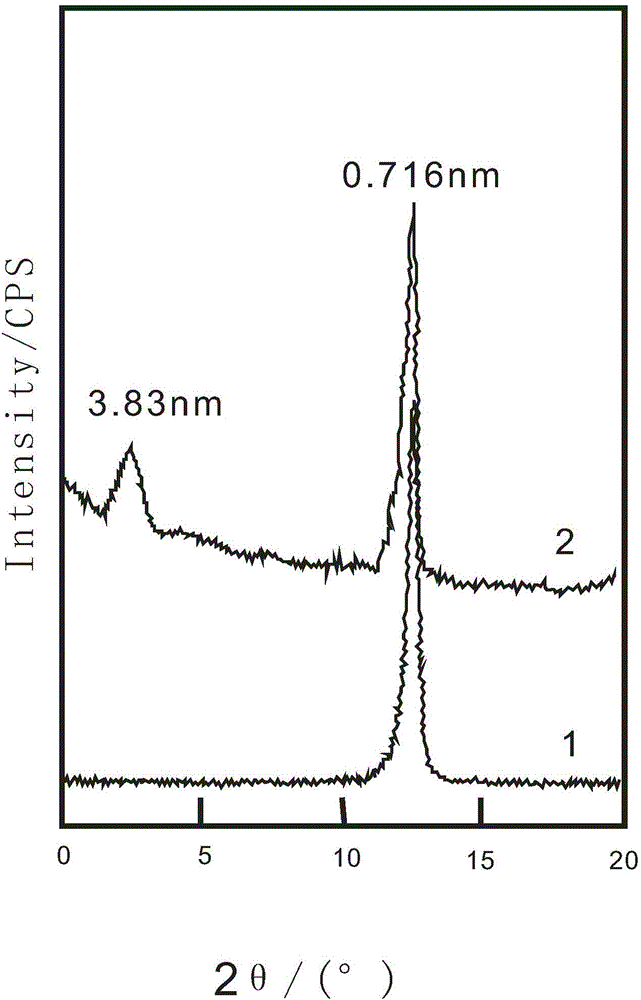

Image

Examples

Embodiment 1

[0050] 1 g of kaolin and 10 ml of 1% by mass DMSO solution were mixed and stirred for 24 hours. After that, it was washed twice with pure water and once with methanol, and dried at 40°C. Mix the dried kaolin / dimethyl sulfoxide compound with sodium lauryl sulfate at a mass ratio of 200:1 and stir evenly, add 10ml of zinc ammonia solution with a concentration of 0.001mol / L, and stir again for 24 hours. Add NaOH at a molar ratio of 1:1 to zinc salt and continue stirring evenly. After 12 hours at 70°C, it becomes zinc oxide antibacterial agent after taking it out.

[0051] Add 1 g of kaolin to 10 ml of 3% DOSO solution by mass, stir for 24 hours, wash it twice with pure water and once with methanol, and then dry it at 50°C to obtain kaolin / dimethylsulfoxide compound; pour 0.1g PVP into the kaolin / dimethyl sulfoxide compound powder after drying and stir evenly; then slowly pour 15ml0.005mol / L silver ammonia solution and stir for 24h; in the above mixed solution with Add hydrazin...

Embodiment 2

[0054] 100g of kaolin and 1000ml of 100% DMSO solution by mass percentage were stirred for 72 hours, washed with pure water twice and once with ethanol, and then dried at 90°C to obtain a kaolin / dimethylsulfoxide complex; The dried kaolin / dimethyl sulfoxide complex and sodium tripolyphosphate were mixed at a mass ratio of 2:1 and stirred evenly; adding 1000ml concentration of 1mol / L zinc nitrate hexahydrate solution, stirring again for 24 hours, and NaOH Add zinc salt and zinc salt according to the molar ratio of 5:1, in the environment of 800 ℃ for 15 minutes, after taking it out, it will become zinc oxide antibacterial agent.

[0055] Add 100g of kaolin to 1000ml of DOSO solution with a mass percentage of 100%, stir for 72 hours, wash it twice with pure water and once with ethanol, and then dry it at 90°C to obtain a kaolin / dimethyl sulfoxide composite Pour 50g of sodium tripolyphosphate into the dried kaolin / dimethyl sulfoxide compound powder and stir evenly; then slowly po...

Embodiment 3

[0058] 50g of kaolin and 500ml of DMSO solution with a mass percentage of 50% were stirred for 48 hours, washed with pure water twice and once with methanol, and then dried at 70°C to obtain a kaolin / dimethylsulfoxide complex; The dried kaolin / dimethyl sulfoxide complex and sodium hexametaphosphate were mixed in a mass ratio of 100:1 and stirred evenly; 500ml of sodium hydroxide solution with a concentration of 0.5mol / L was added, stirred again for 36 hours, and put into After 7 hours at 600°C, it will become zinc oxide antibacterial agent after taking it out.

[0059] Add 50g of kaolin to 500ml of 60% DOSO solution by mass, stir for 24 hours, wash it with pure water twice and once with methanol, and then dry it at 70°C to obtain kaolin / dimethylsulfoxide Compound; dissolve 1g of sodium tripolyphosphate in 80ml of aqueous solution, pour dried kaolin / dimethyl sulfoxide compound powder into the aqueous solution and stir evenly; then slowly pour 500ml of 0.1mol / L of silver ammon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com