A kind of formaldehyde-free amino resin retanning agent

A formaldehyde amino and retanning agent technology, which is applied in the field of retanning agents, can solve the problems of lowering the performance of finished leather, unstable methylene ether bonds, and ineffective removal of aldehydes, and achieve low production costs, low prices, Effect of improving leather feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

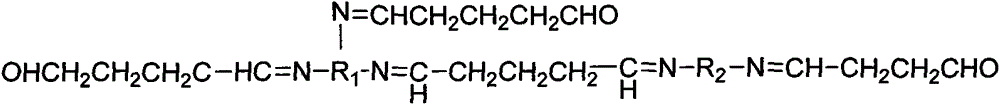

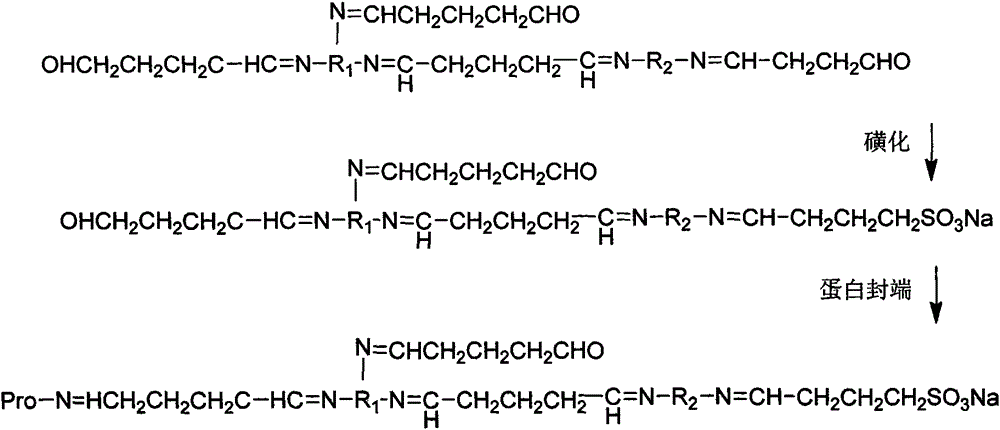

Method used

Image

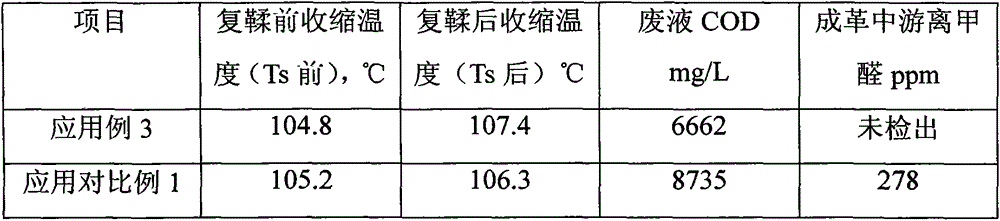

Examples

Embodiment 1

[0033] (1) First add 130kg of melamine, 600kg of glutaraldehyde, and 450kg of pure water into the reaction kettle and stir evenly, then adjust the pH of the reaction system to 7.5 with 5kg of 10% sodium hydroxide solution, and slowly heat to 60~65℃ and keep it at this temperature Incubate for 1.0 hour to obtain a hydroxylated melamine prepolymer.

[0034] (2) Add 150kg of water and 85kg of sodium bisulfite to the prepolymer, increase the temperature to 85°C, and keep the temperature for 2.0h.

[0035] (3) Cool down to 60°C, add 100kg of hydrolyzed collagen with a molecular weight of about 5000 and 200kg of pure water, adjust the pH to 5.5, keep the temperature for 2.0 hours and then lower the temperature to below 45°C, and adjust the pH to neutral to obtain the product.

Embodiment 2

[0037] (1) First add 85kg of dicyandiamide, 400kg of glutaraldehyde, and 250kg of pure water into the reaction kettle and stir evenly, then use 4kg of 10% potassium hydroxide solution to adjust the pH of the reaction system to 8.5, slowly heat to 60~65℃ and The temperature was kept for 2.0 hours to obtain a hydroxylated melamine prepolymer.

[0038] (2) Add 200kg water and 55kg sodium metabisulfite to the prepolymer, heat up to 80℃ and keep for 3.0h

[0039] (3) Cooling down to 60°C, adding 150kg of hydrolyzed collagen with a molecular weight of 20,000 to 40,000 and 180kg of pure water, adjusting the pH to 4.5, keeping the temperature for 1.0 hour and then cooling to below 45°C and adjusting the pH to neutral to obtain the product.

Embodiment 3

[0041] (1) First add 130 kg of melamine, 500 kg of glutaraldehyde, and 300 kg of pure water into the reactor and stir evenly, then add 10 kg of 20% sodium carbonate solution to adjust the pH of the reaction system to 8.0, slowly heat to 60~65℃ and keep it at this temperature Keep the temperature for 1.5 hours to obtain a hydroxylated melamine prepolymer.

[0042] (2) Add 175kg water and 65kg sodium bisulfite to the prepolymer, heat up to 90℃ and keep for 1.5h

[0043] (3) Cool down to 60°C, add 130kg of hydrolyzed collagen with a molecular weight of about 10000-15000 and 175kg of pure water, adjust the pH to 6.5, keep the temperature to below 45°C for 3.0 hours and adjust the pH to neutral to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com