GaN-based light-emitting diode structure and preparation method thereof

A technology of light-emitting diodes and light-emitting layers, which is applied to electrical components, circuits, semiconductor devices, etc., and can solve the problems of severe light absorption of p-type gallium nitride layers, low concentration of Mg-doped hole carriers, and difficulties in p-type doping, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1. Preparation of a GaN-based light-emitting diode with the same-plane electrode structure on a sapphire substrate.

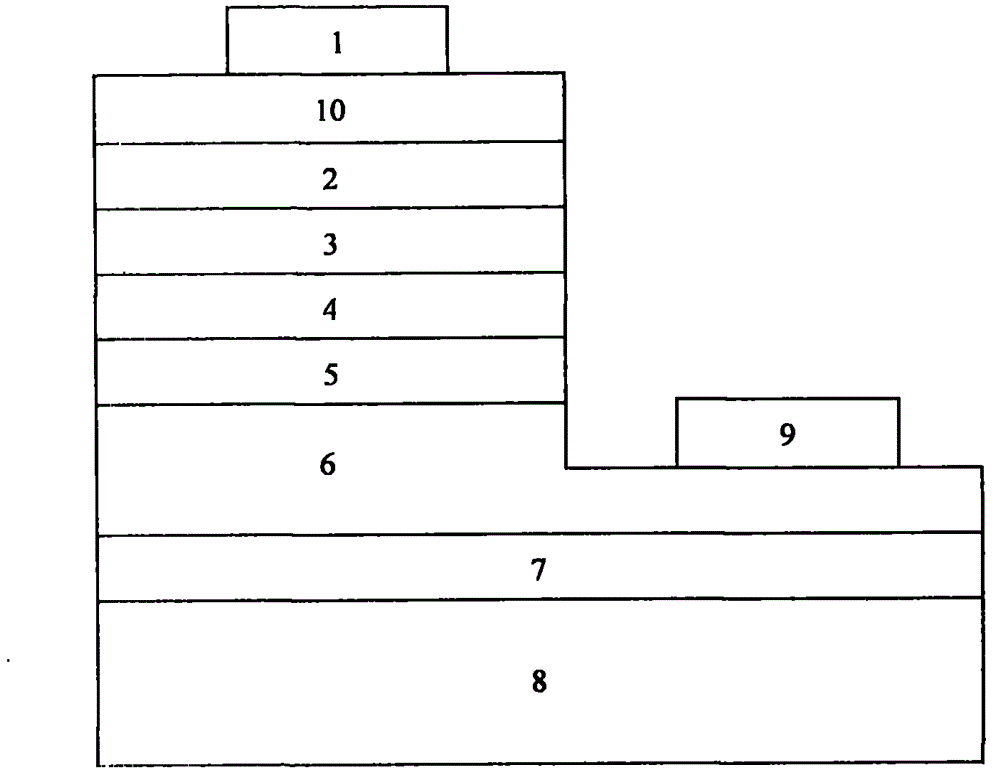

[0044] Such as figure 1 As shown, the GaN-based light-emitting diode structure with the same-plane electrode structure is sequentially sapphire substrate 8, buffer layer 7, n-type GaN conductive layer 6, n-type AlGaN confinement layer 5, active region light-emitting layer 4, A p-type AlGaN confinement layer 3, a p-type diamond thin film conductive layer 2, an ITO transparent conductive layer 10 and a p electrode 1; an n electrode 9 is prepared on an n-type GaN conductive layer 6; the p-type diamond thin film conductive layer 2 is grown On the upper surface of the p-type AlGaN confinement layer 3 , the thickness is 50 nm; the cross-sectional size of the p-type diamond thin film conductive layer 2 is the same as that of the p-type AlGaN confinement layer 3 .

[0045] The preparation method steps are as follows:

[0046] (1) Prepare the epitaxi...

Embodiment 2

[0049] Embodiment 2. Preparation of a GaN-based light-emitting diode with a vertical electrode structure on a silicon carbide substrate.

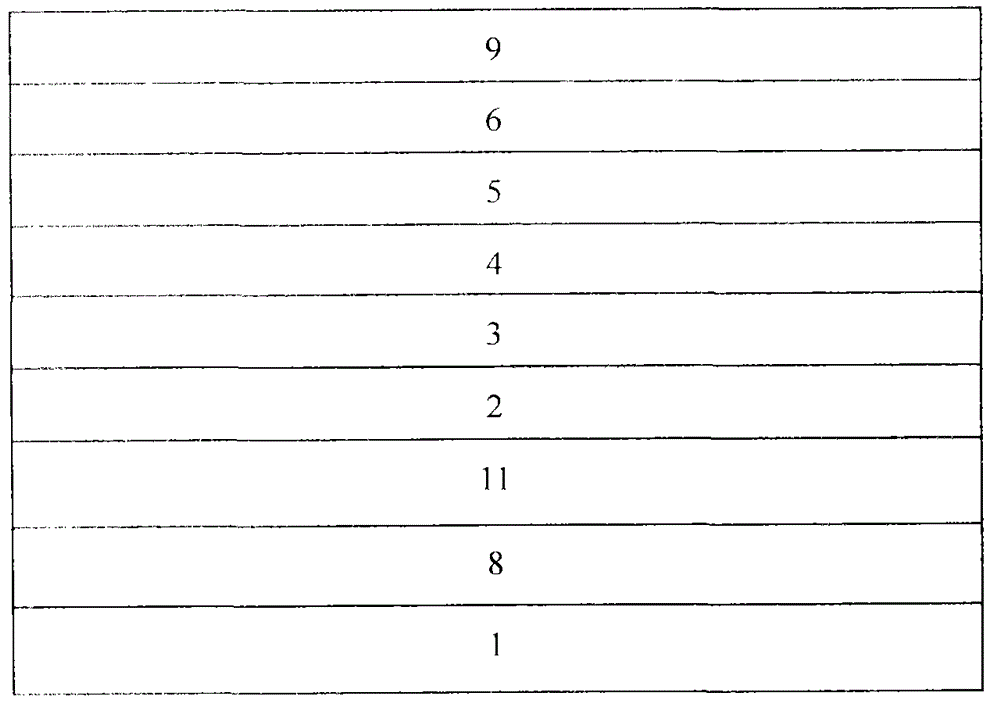

[0050] Such as figure 2 As shown, the vertical electrode structure GaN-based light-emitting diode structure sequentially includes a p-electrode 1, a silicon carbide substrate 8, a p-type ohmic contact layer 11, a p-type diamond thin film conductive layer 2, and a p-type AlGaN confinement layer 3 from bottom to top. , an active region light-emitting layer 4, an n-type AlGaN confinement layer 5, an n-type GaN conductive layer 6 and an n-electrode 9; the p-type diamond film conductive layer 2 is grown on the lower surface of the p-type AlGaN confinement layer 3, with a thickness of 500 nm; the cross-sectional size of the p-type diamond thin film conductive layer 2 is the same as the size of the p-type AlGaN confinement layer 3 .

[0051] The preparation method steps are as follows:

[0052] (1) Prepare the epitaxial wafer to the p-type AlGa...

Embodiment 3

[0055] Embodiment 3. GaN-based light-emitting diodes with the same-plane electrode structure prepared on a silicon substrate.

[0056] Such as figure 1 As shown, as shown in Embodiment 1, the GaN-based light-emitting diode structure sequentially includes a silicon substrate 8, a buffer layer 7, an n-type GaN conductive layer 6, an n-type AlGaN confinement layer 5, and an active region light-emitting layer from bottom to top. 4. P-type AlGaN confinement layer 3, p-type diamond film conductive layer 2, ITO transparent conductive layer 10 and p-electrode 1; the preparation method is as described in Example 1, the difference is:

[0057] The chemical vapor deposition method described in step (1) is a combustion flame chemical vapor deposition method; the thickness of the p-type diamond film conductive layer 2 is 200nm; the temperature condition is 700 degrees Celsius, and the growth time is 30 minutes; the methane, The volume ratio of hydrogen and borane is 1:85:0.002; the doping...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com