Insulation coating composition for non-aromatic electrical sheet, method for manufacturing same, and non-aromatic electrical sheet to which insulation coating composition is applied

A technology of insulating coating and manufacturing method, applied in the direction of heterogeneous insulating materials, insulators, insulators, etc., can solve the problem of solderability, heat resistance, SRA front/rear adhesion and space factor degradation, and increase coating thickness and other issues, to achieve the effect of excellent insulation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

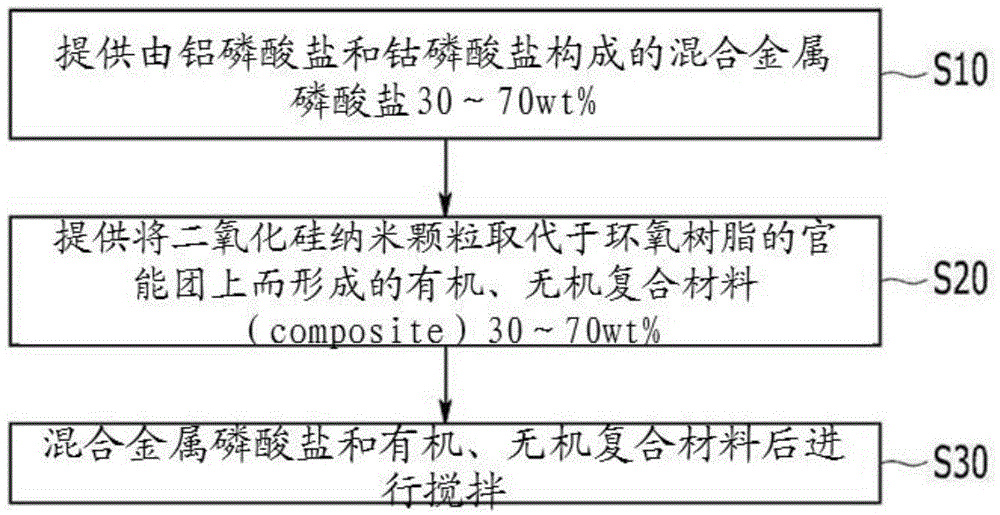

Method used

Image

Examples

Embodiment 1

[0096] A high-grade non-oriented electrical steel sheet (150×50mm) with a thickness of 0.35mm containing 3.15% by weight of silicon (Si) was used as a sample, and the solution prepared in Table 1 was used with a bar coater (bar Coater) and roll coater (roll coater) coat each prepared sample to a specified thickness (0.6-0.8μm), and then maintain it in a drying oven at a temperature range of 300-750°C for 10-30 seconds Cool slowly in air.

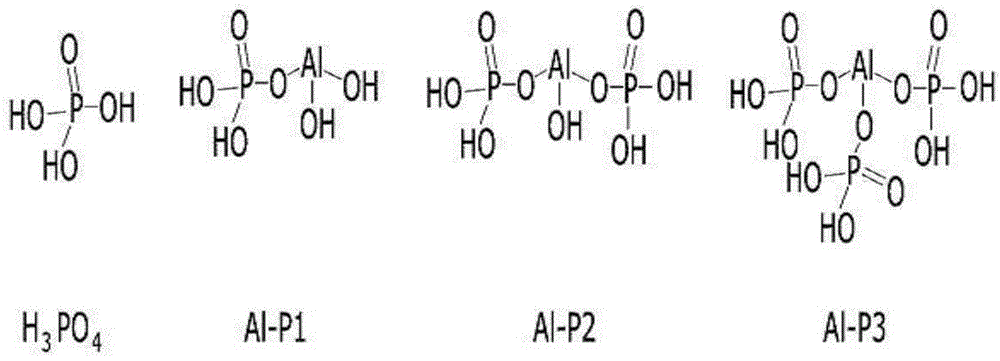

[0097] Table 1 shows when including water (H 2 O) 15wt% and free phosphoric acid (H 3 PO 4 ) Aluminum hydroxide (Al(OH) in 100g of 85wt% aqueous solution 3 ), the solution stability under different injection amounts of ), the amount of free phosphoric acid remaining after the reaction, and the forms of aluminum (Al) and phosphorus (P) (single bond (Al-P), double bond (Al=P) and triple bond (Al=P)) binding amount.

[0098] [Table 1]

[0099] Solution stability under different metal phosphate species and adhesion after SRA

[0100]

...

Embodiment 2

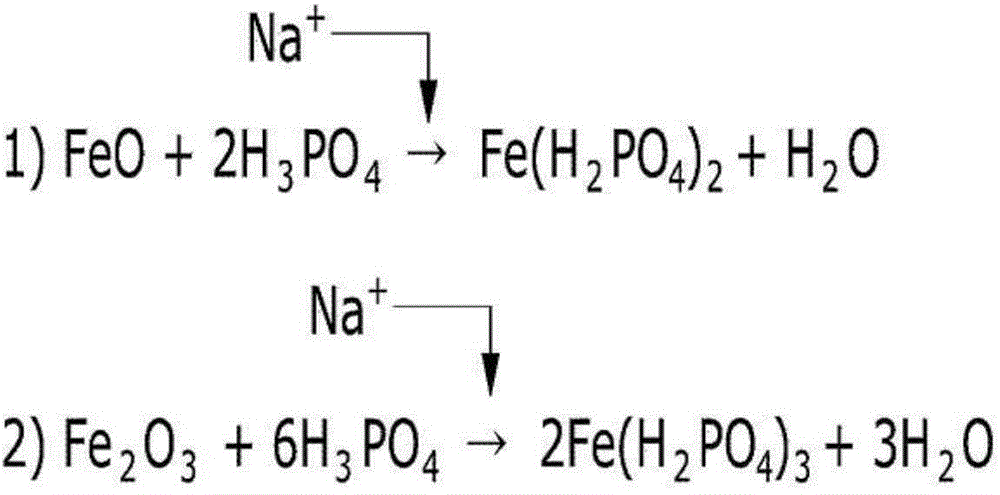

[0105] Table 2 shows that in mixed metal phosphates and silica (SiO 2 ) Solution stability, coating operability, surface state, corrosion resistance and insulation of nanocomposites under different mixing ratios. Among them, the mixed metal phosphate is based on 100g of free phosphoric acid, respectively replacing cobalt hydroxide (Co(OH) 2 )3g and aluminum hydroxide (Al(OH) 3 ) 30g of cobalt phosphate (Co(H 3 PO 4 ) 3 ) and aluminophosphate (Al(H 3 PO 4 ) x=1~3 ) composition, wherein the mixing ratio of cobalt phosphate / aluminophosphate is maintained at 0.1.

[0106] Wherein, the particle diameter of the silicon dioxide nanocomposite material used is 10 nm, and the silicon dioxide solid content is 30%. The solution stability and coating workability are excellent when the ratio of composite material to metal phosphate is 8:2 to 4:6. When the ratio of composite material to metal hydrochloric acid is 8:2~3:7, a very beautiful surface without defects can be obtained.

...

Embodiment 3

[0113] Based on the results of Examples 1 and 2, it is shown that when the ratio of composite material to metal phosphate is 6:4 to 5:5, different injection ratios of cobalt phosphate / aluminophosphate, silica nanocomposite Insulation and surface properties under different composition ratios of organic epoxy resin and silica particles in the material.

[0114] The particle size of the silica nanocomposite used here was 10 nm. Use water to control the specific gravity of each coating composition to 1.1, and use a No. 3 bar coater (bar coater) to coat it to a thickness of 0.6-0.8 μm, and heat-treat it at a temperature range of 500-750 ° C for 10-30 seconds Finally, the insulation and surface properties of the coated layer before / after stress relief annealing (SRA) were compared. Furthermore, Comparative Examples 1 and 2 show the surface properties of chrome-based and chrome-free thin film products.

[0115] [table 3]

[0116] Comparison of insulation and surface properties at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com