Large-stroke column coordinate two-photon polymerization processing method and device

A technology of two-photon polymerization and processing methods, applied in metal processing equipment, manufacturing tools, laser welding equipment, etc., can solve the problem of affecting the processing accuracy of two-photon polymerization, unsuitable for three-dimensional micro-nano structure devices, limited travel and operating frequency, etc. problem, to achieve the effect of equal exposure time, high productivity, and large working stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

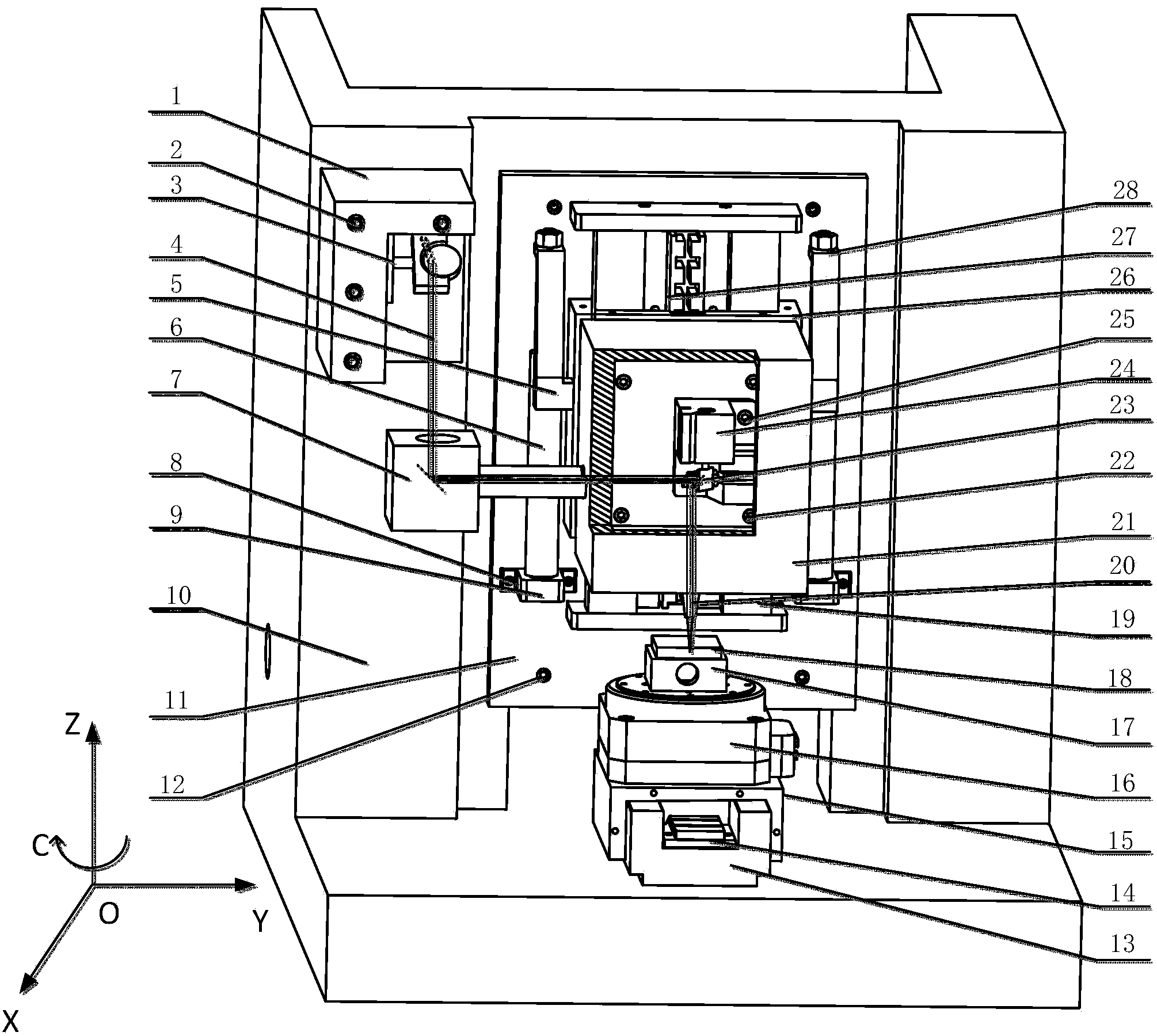

[0058] A kind of specific embodiment that realizes device of the present invention is as follows:

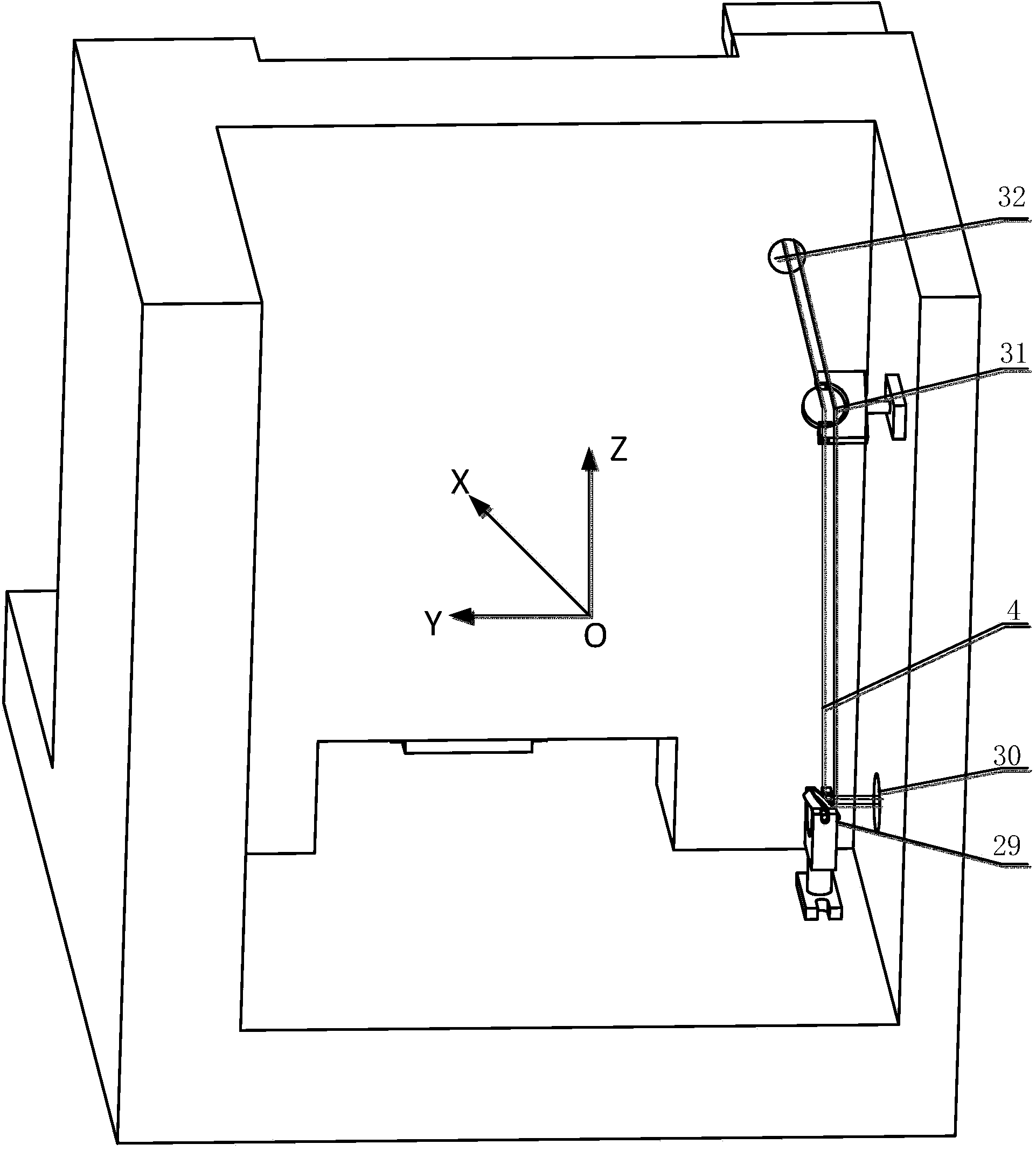

[0059] The support 1 is connected to the marble bed 10 through 4 hexagon socket head screws 2, the beam splitter 3 is installed on the support 1, the reflector 3 7 is fixedly connected with the vibrating mirror box 21, and the x-axis sliding plate 15 Slidingly connected with the air-floating linear guideway 13, the linear motor 14 is connected with the air-floating linear guideway 13 and installed on the marble bed 10, the C-axis turntable 16 is stacked on the x-axis slide plate, the base 17 is connected to the C-axis The turntable is fixedly connected, the z-axis sliding plate 26 is slidingly connected to the air-floating linear guide rail 2 19, the linear motor 27 is connected to the air-floating linear guide rail 2 19, the air-floating linear guide rail 2 19 is connected to the bottom plate 11, and the bottom plate 11 passes through 6 inner hexagons The cylindrical head screw...

Embodiment approach

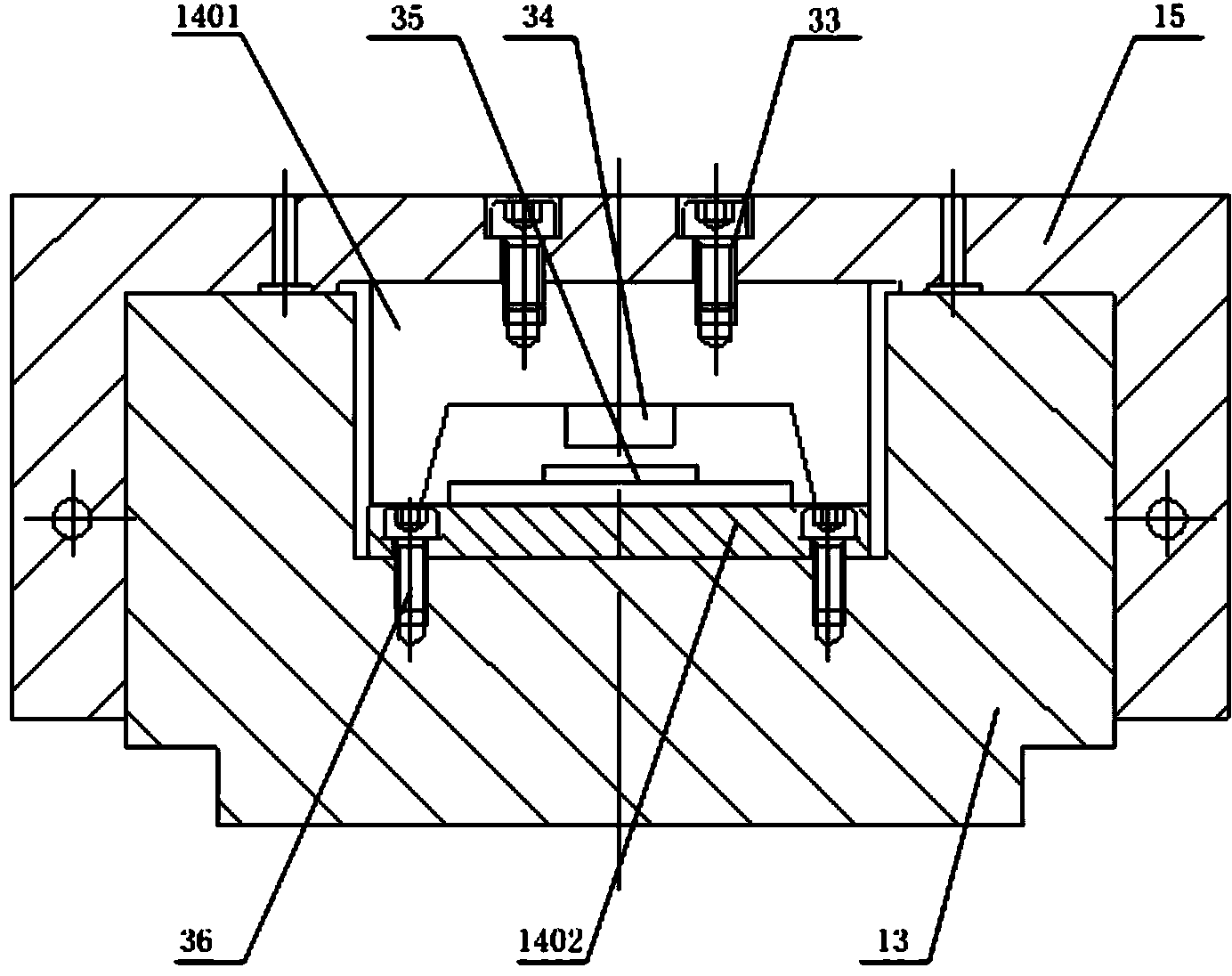

[0060] One embodiment of the present invention is: a linear motor is composed of a mover 1401 and a stator 1402, the stator is installed on the sliding plate 15 through a hexagon socket head screw 33, and the stator is installed on the slide plate through a hexagon socket head screw 36 15 on.

[0061] One embodiment of the present invention is: the C-axis turntable 16 is equipped with a rotary grating 1609, a reading head 3 1611, and the reading head 3 1611 is fixedly connected with the fixing seat 1610, supported by an air bearing shaft 1602, which is mounted on an air bearing On 1604, the servo motor is composed of a servo motor stator 1607 and a servo motor rotor 1608. The air bearing 1604 is installed on the support frame 1603 through the hexagon socket head screw 1601, and the support frame is installed on the base 1612 through the socket head cap screw 1605. The intake valve 1606 is fixedly connected to the outside of the base;

[0062] One embodiment of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com