Novel sheet material and application thereof

A new material and board technology, applied in wood compression, wood treatment, impregnated wood, etc., can solve the problems of unclear process parameters, poor operability, and low production efficiency, and achieve clear process parameters and strong operability , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

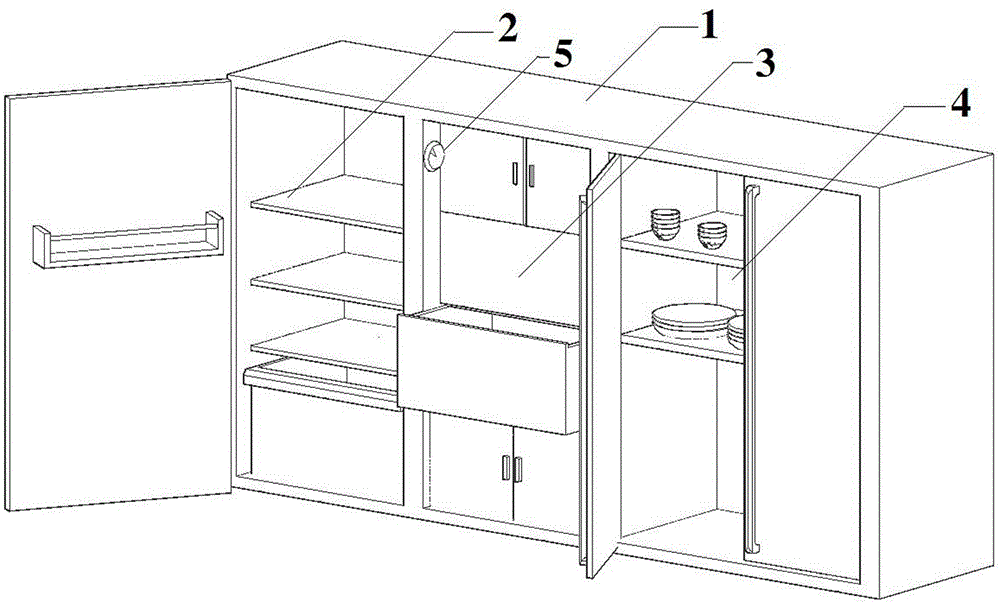

Image

Examples

Embodiment Construction

[0029] First prepare light-colored water-soluble low-molecular-weight phenolic resin glue. The raw materials are phenol, formaldehyde, sodium hydroxide and melamine. The molar ratio of the first three is phenol:formaldehyde:sodium hydroxide=1:1.5~3.0:0.1~0.2, melamine The amount of input is 20-40% of the total amount of phenol, and the process is as follows:

[0030] (a) Melt phenol, when the temperature is 60-65°C, add NaOH, the amount added accounts for 50-70% of the total NaOH dosage, and react for 20 minutes;

[0031] (b) Adding formaldehyde, the first addition accounted for 70-80% of the total formaldehyde dosage, raised the temperature to 85-95°C, and reacted for 10-30 minutes; lowered the temperature to 60-75°C, added the second batch of formaldehyde, the amount added Accounting for 10-15% of the total dosage of formaldehyde; and adding NaOH, the amount added accounts for 10-20% of the total dosage of NaOH;

[0032] (c) Heat up to 85-95°C, keep warm for 10-20 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com