Zero-firing-shrinkage cordierite honeycomb ceramic carrier and preparation method thereof

A cordierite honeycomb and ceramic carrier technology is applied in ceramic products, other household appliances, applications, etc., and can solve the problems of large firing shrinkage, low yield, large drying shrinkage of cordierite honeycomb ceramics, etc. The effect of high firing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

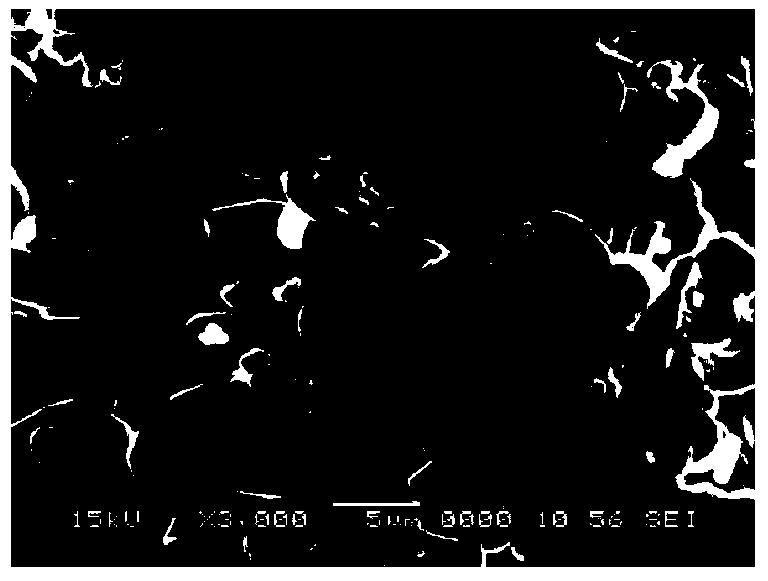

[0039] figure 1It is a kind of flaky alumina with an aspect ratio of 4:1, 20.17% of D50=20μm flake alumina with an aspect ratio of 4:1, 4.11% of D50=2.0μm highly active magnesia, 15.24% of D50=4.0μm fused quartz, 27.12% of D50=15μm flake talc, 33.36% of D50=6μm raw kaolin are mixed as inorganic powder, the sum of inorganic powder is 100%, plus 4% Methylcellulose, 0.5% silicone polyether copolymer (such as Dow Corning's DC series), 1% soybean oil and 35% water. After fully dry mixing, kneading, and vacuum smelting, it is extruded into a honeycomb ceramic catalyst carrier with a diameter of 330.2×152.4mm and 400 holes / square inch. After drying, it is fired at 1415°C for 8 hours, and the firing shrinkage is 0. %, the firing pass rate is 98.7%. The performance of the prepared cordierite honeycomb ceramic carrier is: thermal expansion coefficient 0.82×10 -6 / °C (room temperature-800°C), water absorption rate is 33%, compressive strength parallel to the axial direction is 16.7MPa...

Embodiment 2

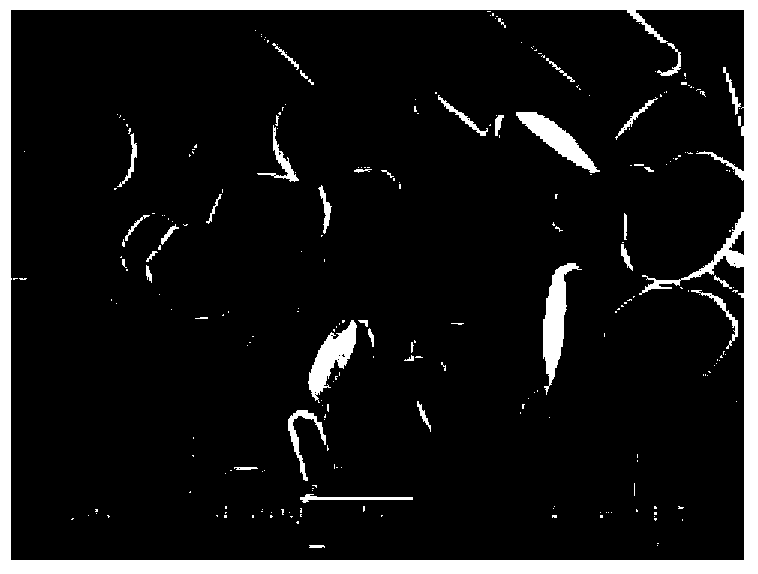

[0041] figure 2 It is a kind of flaky alumina with an aspect ratio of 6:1, 24.55% of D50=15μm flake alumina with an aspect ratio of 6:1, 6.85% of D50=1.0μm highly active magnesia, 25.40% of D50=5.0μm fused silica, 19.37% of D50=10μm flake talc, 23.83% of D50=4μm raw kaolin are mixed as inorganic powder, the total amount of inorganic powder is 100%, plus 5% Methylcellulose, 0.5% silicone polyether copolymer (such as Dow Corning's DC series), 1% soybean oil and 34% water. After fully dry mixing, kneading, vacuum refining, extruding into a honeycomb ceramic catalyst carrier of Φ330.2×152.4mm, 400 holes / square inch, after drying, it is fired at 1415°C for 8 hours, and the carrier shrinks to 0%, the firing pass rate is 99.2%. Properties of cordierite honeycomb ceramic carrier: thermal expansion coefficient 0.78×10 -6 / °C (room temperature-800°C), water absorption rate is 34%, compressive strength parallel to the axial direction is 18.4MPa, thermal shock performance: 650°C air c...

Embodiment 3

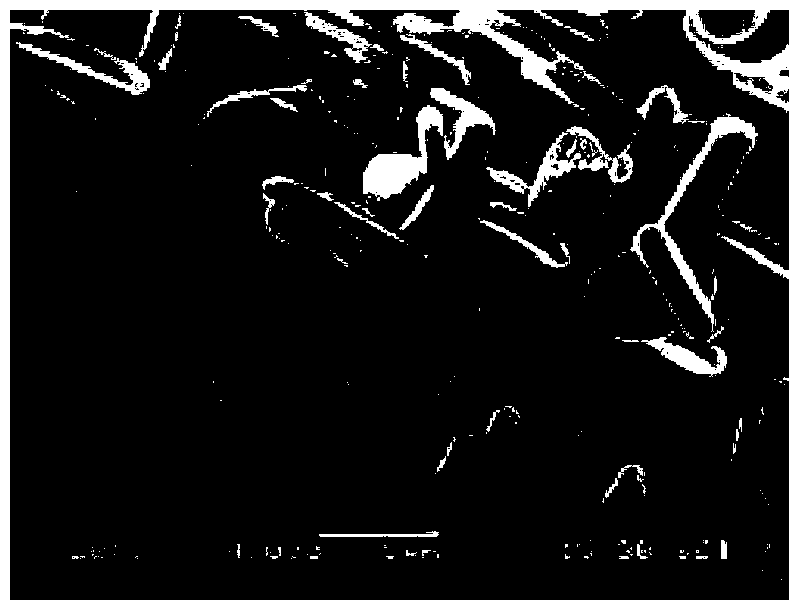

[0043] image 3 It is a kind of flaky alumina with an aspect ratio of 8:1, 31.12% of flaky alumina with an aspect ratio of D50=10μm, 10.56% of high-activity magnesium oxide with D50=0.6μm, 40.54% of D50=6.0μm fused silica, 7.65% of D50=6μm flake talc, 10.13% of D50=2μm raw kaolin are mixed as inorganic powder, the sum of inorganic powder is 100%, plus 6% Methylcellulose, 0.8% silicone polyether copolymer (such as Dow Corning's DC series), 1% soybean oil and 33% water. After fully dry mixing, kneading, and vacuum smelting, extrude into a honeycomb ceramic catalyst carrier of Φ330.2×152.4mm, 400 holes / square inch, after drying, cut, and fire at 1415°C for 8 hours. The final firing shrinkage is 0%, and the firing pass rate is 100%. The performance of the obtained cordierite honeycomb ceramic carrier is: thermal expansion coefficient 0.7×10 -6 / °C (room temperature-800°C), water absorption rate of 36%, compressive strength parallel to the axial direction of 19.0MPa, thermal shoc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com