A kind of loose and anti-adhesive high-performance polycarboxylic acid admixture and its preparation method and application

An anti-adhesive polycarboxylic acid and admixture technology, which is applied in the field of loose and anti-adhesive high-performance concrete admixtures, can solve problems such as increased viscosity, bottoming and poor flow performance, and achieve lower viscosity and lower raw material costs , enhance the effect of adsorbing water molecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

[0031] 1) In a 1000ml four-necked flask, add 380g of deionized water as bottom water, add 95g of polymerized monomer (IV) and 5.2g of chain transfer agent sodium allyl sulfonate SAS, dissolve while stirring and heat up to 60~ 65°C.

[0032] 2) Add a mixture of 2.1 g of hydrogen peroxide (30%) and 10.5 g of pure water under nitrogen protection, and stir for 5 minutes.

[0033] 3) Start to drop the ester-based macromonomer MPEGMAA 148g and 210g of deionized water.

[0034] 4) At the same time drop by methacrylic acid 50g and EDTMP (embodiment 2 is the compound of PBTC) 5.5g composition.

[0035] 5) Add dropwise the initiator consisting of APS6.3g and deionized water 105g at the same time.

[0036] 6) Adding control The dropping time is 2 to 3 hours.

[0037] 7) Then add 0.5 g of acrylamide, a rheology adjusting assistant, at one time.

[0038] 8) Then heat-retain and react for 1 hour, and the temperature is controlled at 80-90°C.

[0039] 9) It is detected th...

Embodiment 3

[0041] 1) Add 600g of 60% HPEG to a 1000ml four-necked flask, and add 3.0g of SAS, dissolve while stirring and heat up to 50-55°C.

[0042] 2) Add APS 1.2g and stir for 10 minutes.

[0043] 3) A mixed solution consisting of 38 g of acrylic acid, 5 g of HEDP and 8.75 g of deionized water was added dropwise.

[0044] 4) Simultaneously dropwise add a mixed solution consisting of 95 g of AA-LS polymer and 150 g of deionized water.

[0045] 5) After the dropwise addition is completed, 0.5 g of APS is added for the second time, and the temperature is raised to 60°C.

[0046] 6) Add 3g of urea, keep warm for 1 hour, then cool to 40-45°C, adjust P with liquid caustic soda H 6 to 6.5 is enough.

[0047] 7) Measure the solid content and replenish water to adjust the solid content to 40%±0.5%.

Embodiment 4

[0049] 1) In a 1000ml four-neck flask, add 600g of 60% concentration of polyethylene glycol methacrylate MPEGMAA and 100g of 60% concentration of MPEGAA, and add SAS3.0g, dissolve and heat up to 50-55°C while stirring.

[0050] 2) Add APS 1.2g and stir for 10 minutes.

[0051] 3) Add acrylic acid dropwise 38g, HEDP5g and deionized water 8.75g.

[0052] 4) Simultaneously dropwise add a mixed solution consisting of 95 g of AA-LS polymer and 150 g of deionized water.

[0053] 5) After the dropwise addition is completed, 0.5 g of APS is added for the second time, and the temperature is raised to 60°C.

[0054] 6) Add 3g of urea, keep warm for 1 hour, then cool to 40-45°C, adjust P with liquid caustic soda H 6 to 6.5 is enough.

[0055] Measure the solid content and replenish water to adjust the solid content to 40% ± 0.5%.

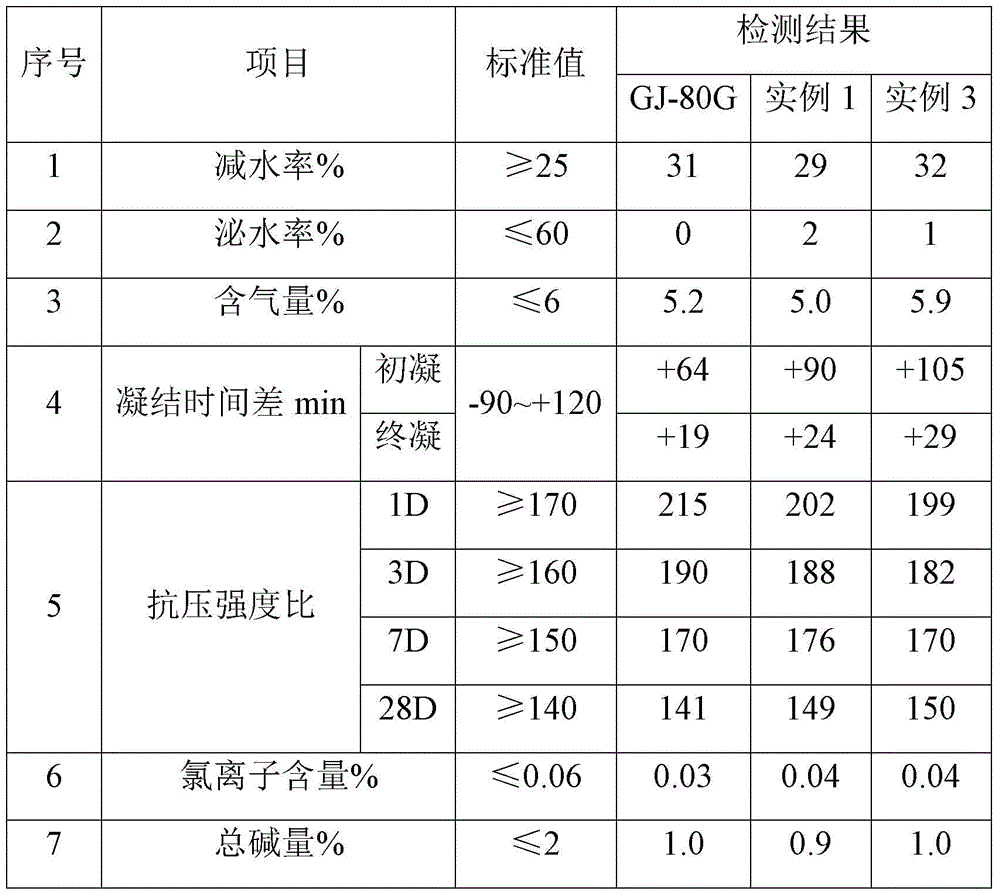

[0056] Detection and Application:

[0057] 1) Concrete performance comparison after adding example 1, example 2 and GJ-80G

[0058]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com