Method for rapidly preparing polythiophene in mixed solvent system

A mixed solvent system and mixed solvent technology, applied in the field of rapid preparation of polythiophene, can solve the problems of the influence of photoelectric response performance of polythiophene, difficult removal of surfactants, prolonged post-treatment period, etc., and achieve fast product processing and selectable range. Wide range of effects with easy temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A. The thiophene monomer (colorless transparent liquid, figure 1 A) and ammonium persulfate / divalent copper salt as oxidant (with (NH 4 ) 2 S 2 O 8 / CuCl 2 ·2H 2 O as an example) is completely dissolved in a mixed solvent system of water and alcohols (taking ethanol as an example) at a mass ratio of 50g:50g to form a stable colorless and transparent mixed solution ( figure 1 B), where thiophene, (NH 4 ) 2 S 2 O 8 , CuCl 2 ·2H 2 The molar ratio between the three of O is 0.05mol:0.05mol:0.005mol.

[0021] B. The mixed solution is condensed and refluxed for 6 hours under mechanical stirring and 50℃ water bath conditions. The color of the solution gradually deepens from colorless and transparent to yellow, brown to black with precipitation ( figure 1 C). The final precipitate is filtered by suction, washed with a mixture of deionized water and ethanol, and dried at 50°C to obtain black polythiophene powder ( figure 1 D).

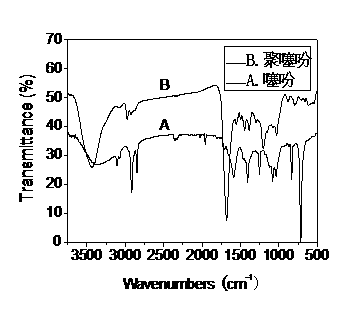

[0022] C. Through infrared spectrum analysis ( figure 2 )...

Embodiment 2

[0028] This embodiment is basically the same as the first embodiment, but the difference is that water and acetone are mixed into a mixed solvent system at a mass ratio of 50g:50g as the solvent for the polymerization reaction, and (NH 4 ) 2 S 2 O 8 / FeCl 3 ·6H 2 O oxidation / catalysis system is used as the oxidant of polymerization reaction, thiophene, (NH 4 ) 2 S 2 O 8 , FeCl 3 ·6H 2 The molar ratio between the three of O is 0.05mol:0.05mol:0.005mol.

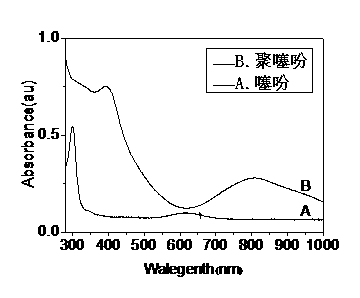

[0029] The result of UV-Vis spectroscopy characterization of the synthesized sample shows that the sharp absorption of thiophene near 300nm is obviously red-shifted and broadened, indicating that its conjugation degree is significantly increased; and the visible broad absorption near 770nm also proves that it has Stronger π-electron delocalization, that is, the length of the conjugated chain increases, but it is smaller than that of Example 1, so its molecular weight is lower than that of Example 1.

[0030] Using N,N-dimethylformami...

Embodiment 3

[0032] This embodiment is basically the same as the first embodiment, but the difference is that water and acetic acid are mixed into a mixed solvent system at a mass ratio of 50g:50g as the solvent for the polymerization reaction, and H 2 O 2 / FeCl 3 ·6H 2 O oxidation / catalysis system is used as the oxidant of polymerization reaction, thiophene, H 2 O 2 , FeCl 3 ·6H 2 The molar ratio between the three O is 0.05mol:0.1mol:0.005mol.

[0033] The result of UV-Vis spectroscopy characterization of the synthesized sample shows that, similar to Example 1, the sharp absorption of thiophene near 300nm is significantly red-shifted and broadened, indicating that the degree of conjugation is significantly increased; and the visible region near 790nm The broad absorption also proves that it has strong π electron delocalization, that is, the length of the conjugated chain increases, and it is larger than that of the second embodiment.

[0034] Using N,N-dimethylformamide as the solvent, the mole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com