A kind of continuous reaction hydrogen production method of photosynthetic bacteria

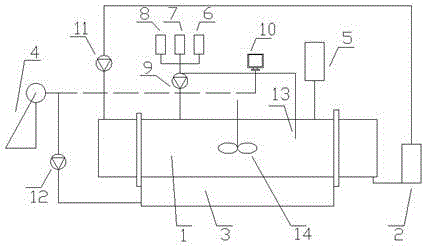

A photosynthetic bacteria and reaction technology, which is applied in the field of continuous reaction of photosynthetic bacteria to produce hydrogen, can solve the problems such as the reduction of the hydrogen production efficiency of photosynthetic bacteria and the conversion rate of substrates, the large pressure difference between the gas collecting pipeline and the reactor, and the difficulty of cleaning the reactor. , to achieve the effect of improving substrate utilization, increasing efficiency and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

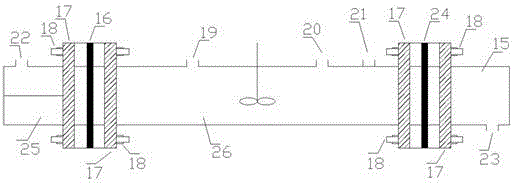

[0033] First, through the injection port 40 of the incubator 44 in the photosynthetic bacteria culture device 7 after sterilization, the photosynthetic bacteria liquid and the growth medium with a volume ratio of 1:4 are injected in the incubator 44 to carry out proliferation and cultivation. Bacteria concentration OD in the incubator 660nm After reaching 1.6 to 1.9, pump 45 to transport 4 / 5 to 5 / 6 of the bacterial solution by volume into the concentration tank 46, and pass through the concentration tank 46, which is 4 / 5 to 5 / 6 box length away from the bacterial solution inlet Concentrate the microporous membrane III39 with a pore size ≤ 0.22 μm, and stop concentrating when the concentration of the bacterial solution reaches 2 to 3 times the concentration of the original bacterial solution. The separated culture solution is returned to the incubator 44 through the liquid inlet 43, and new culture solution is added through the injection port 40 to continue to proliferate and cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com