Method for processing brick tea from Lingyun Baihao tea

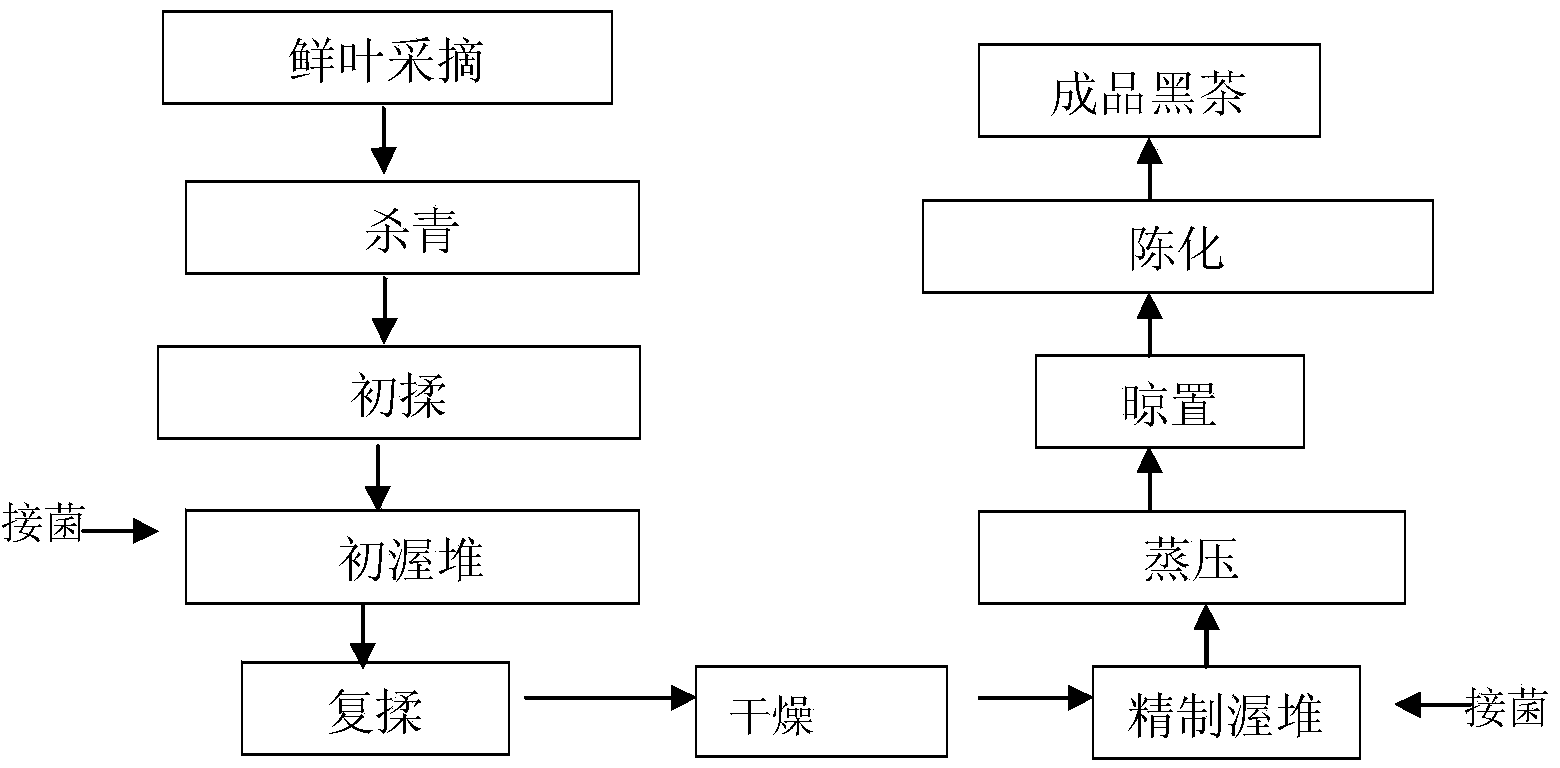

A technology of Lingyun Pekoe tea and black tea, which is applied in the field of tea processing, can solve problems such as unbalanced bacterial fermentation, less bacterial communities, and uneven tea quality, and achieve the effects of mellow and refreshing taste, improved taste and nutrition, and reduced procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take the fresh tea leaves of Pekoe tea with one bud and two leaves, spread them in the air until the water content drops to about 60%, and finish them in time. Use a hot air degreening machine or a steam degreening machine for degreening, the temperature inside the cylinder is about 170-180°C, the amount of leaves to be de-greened is 200-250kg / h, and the de-greening time is about 1.5-2.0 min. 6CR-45-II and 6CR-55-II tea kneading machines are used, and the amount of leaves thrown at one time is 10-12kg. The speed is 75-90r / min, and the kneading time is 12-15 minutes in the whole process. After the initial kneading, before entering the initial ointment pile step, the amount of the inoculation fungus is 3 × 10 per kilogram of fresh leaf raw material. 4 The spores of a loose cyst fungus are inserted into the pile of tea leaves by spraying the bacterial liquid and stirring evenly. The height of the pile of first fertilization is 25 cm, and the time is 2 to 3 days, during wh...

Embodiment 2

[0033] Take the fresh tea leaves of Pekoe tea with one bud and three to five leaves, spread them out in the air until the water content drops to about 60%, and kill them in time. Use a hot air degreening machine or a steam degreening machine for degreening, the temperature inside the cylinder is about 170-180°C, the amount of leaves to be de-greened is 200-250kg / h, and the de-greening time is about 1.5-2.0 min. 6CR-45-II and 6CR-55-II tea kneading machines are used, and the amount of leaves thrown at one time is 10-12kg. The speed is 75-90r / min, and the kneading time is 12-15 minutes in the whole process. After initial kneading, before entering the initial ointment heap step, the amount of inoculated saccharomyces was 4.5×10 per kilogram of fresh leaf raw material. 4 The spores of a loose cyst fungus are inserted into the pile of tea leaves by spraying the bacteria solution and stirring evenly. Re-knead the tea dhool that has been stacked at the beginning to make the water c...

Embodiment 3

[0037] Take the fresh tea leaves of Pekoe tea with one bud and two leaves, spread them in the air until the water content drops to about 60%, and finish them in time. Use a hot air degreening machine or a steam degreening machine for degreening, the temperature inside the cylinder is about 170-180°C, the amount of leaves to be de-greened is 200-250kg / h, and the de-greening time is about 1.5-2.0 min. 6CR-45-II and 6CR-55-II tea kneading machines are used, and the amount of leaves thrown at one time is 10-12kg. The speed is 75-90r / min, and the kneading time is 12-15 minutes in the whole process. After initial kneading, before entering the initial ointment heap step, the amount of inoculated saccharomyces is 5.0×10 per kilogram of fresh leaf raw material. 4 The fungus spores are inserted into the pile of tea leaves by spraying the bacteria solution and stirring evenly. The height of the pile is 35cm, and the time is 2 to 3 days, during which it is turned irregularly. Re-knead t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com