Fermented sauced bone meal and preparation method thereof

A technology of fermented sauce and fragrant bone, applied in the field of food processing, to achieve the effect of complete variety, unique flavor and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

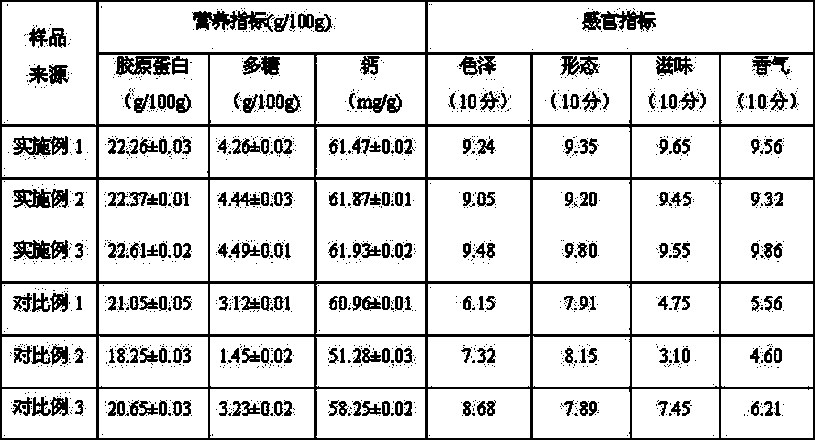

Embodiment 1

[0029] A fermented sauce-flavored bone powder and a preparation method thereof, the steps are as follows:

[0030] (1) Wash 250g of lamb bones, 220g of beef bones, 100g of pork bones, 180g of duck bones, 100g of goose bones, and 80g of chicken bones, drain them and put them in a high-pressure cooker to cook until soft. The cooking conditions are: pressure 0.20MPa , temperature 140°C, time 30-40min. Then dry, pulverize, add deionized water 1 times the weight of the bone, and beat;

[0031] (2) Add compound enzyme to the above bone pulp at a weight ratio of 0.1%, and enzymolyze it at a temperature of 45°C and a pH of 6.5 for 8 hours;

[0032] (3) Add 1.5% (W / W) lactose after the enzymatic hydrolysis is completed, and insert the mixed bacterial solution of Lactobacillus plantarum and Saccharomyces cerevisiae with a CFU ratio of 1.5:1 according to the inoculum size of 4%, and the mixed bacterial solution is effective The total number of bacteria is 6.7×10 11 ~8.2×10 12 per g, ...

Embodiment 2

[0036] A fermented sauce-flavored bone powder and a preparation method thereof, the steps are as follows:

[0037] (1) Wash 300g of lamb bones, 280g of beef bones, 225g of pork bones, 200g of duck bones, 180g of goose bones, and 160g of chicken bones, drain them and put them in a high-pressure cooker to cook until soft. The cooking conditions are: pressure 0.20MPa , temperature 140°C, time 30-40min. Then dry, pulverize, add deionized water 1 times the weight of the bone, and beat;

[0038] (2) Add compound enzyme to the above bone pulp at a weight ratio of 1%, and enzymolyze it at a temperature of 60°C and a pH of 7.5 for 12 hours;

[0039] (3) Add 2% (W / W) lactose after the enzymatic hydrolysis is completed, and insert the mixed bacterial solution of Lactobacillus plantarum and Saccharomyces cerevisiae with a CFU ratio of 2.5:1 according to the inoculum size of 10%, and the mixed bacterial solution is effective The total number of bacteria is 6.7×10 11 ~8.2×10 12 per g, aer...

Embodiment 3

[0043] A fermented sauce-flavored bone powder and a preparation method thereof, the steps are as follows:

[0044] (1) Wash 275g of lamb bones, 250g of beef bones, 165g of pork bones, 190g of duck bones, 140g of goose bones, and 120g of chicken bones, drain them and put them in a high-pressure cooker to cook until soft. The cooking conditions are: pressure 0.20MPa , temperature 140°C, time 30-40min. Then dry, pulverize, add deionized water 1 times the weight of the bone, and beat;

[0045] (2) Add compound enzyme to the above bone pulp at a weight ratio of 0.5%, and enzymolyze it at a temperature of 52°C and a pH of 7.0 for 10 hours;

[0046] (3) Add 1.75% (W / W) lactose after the enzymolysis is completed, and insert the mixed bacterial solution of Lactobacillus plantarum and Saccharomyces cerevisiae with a CFU ratio of 2:1 according to the inoculum size of 7%, and the mixed bacterial solution is effective The total number of bacteria is 6.7×10 11 ~8.2×10 12 Individual / g, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com