Drilling fluids that reduce formation damage and drilling fluids used in coalbed methane development drilling

A drilling fluid and formation technology, applied in the field of drilling fluid, can solve the problems of high cost and unsatisfactory effect, and achieve the effects of reducing damage, reducing water lock effect and reducing capillary resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

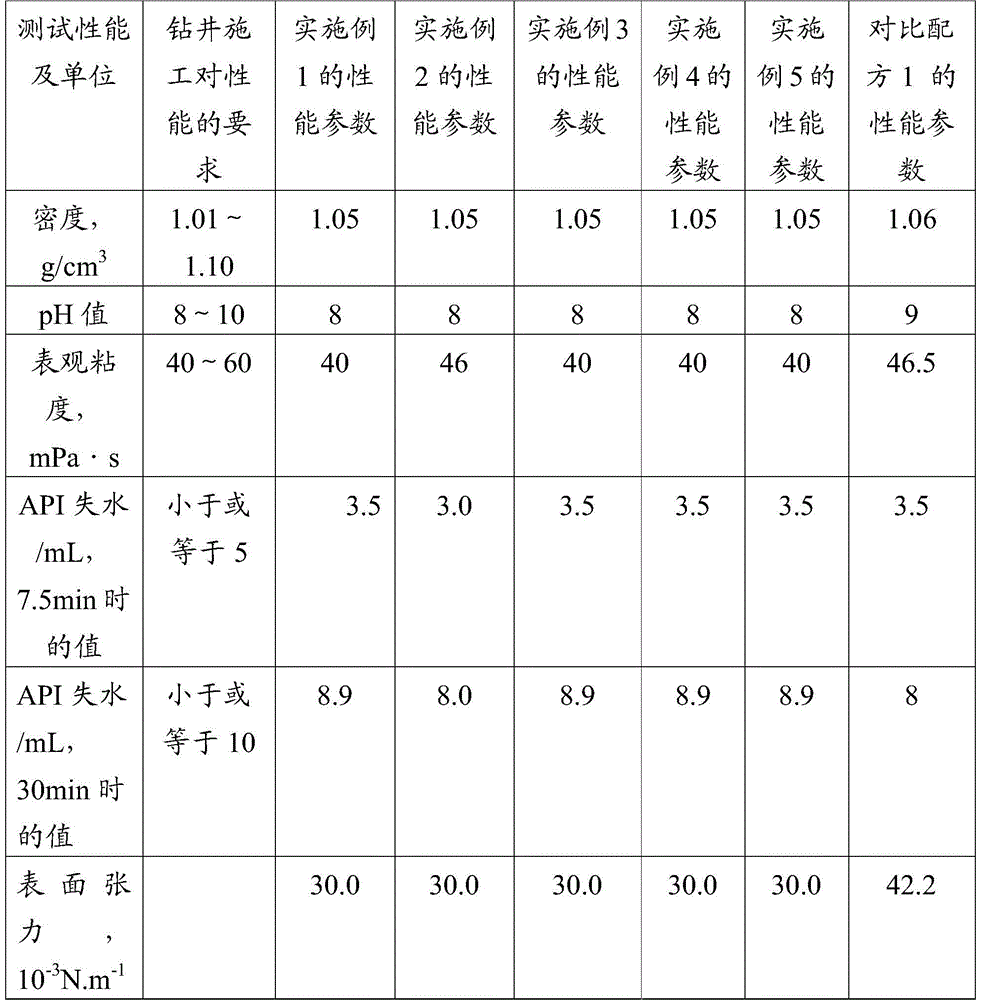

Embodiment 1

[0045] The formula is: fresh water 800g, acrylic acid, acrylamide and 2-acrylamide-2-methylpropanesulfonic acid terpolymer (hereinafter referred to as HYJ-1) 8g, polyanionic cellulose (hereinafter referred to as PAC-LV) 4g, Emulsified asphalt 8g, polyethylene glycol 16g, inorganic sodium bentonite 12g, fluorocarbon surfactant 8g, sodium carbonate 24g. The mass ratio of each component is water: HYJ-1: PAC-LV: emulsified asphalt: polyethylene glycol: inorganic sodium bentonite: fluorocarbon surfactant: sodium carbonate = 100: 1: 0.5: 1: 2: 1.5 :1:3.

Embodiment 2

[0047] The formula is: fresh water 800g, HYJ-18g, PAC-LV16g, emulsified asphalt 8g, polyethylene glycol 16g, inorganic sodium bentonite 12g, fluorocarbon surfactant 8g, sodium carbonate 24g. The mass ratio of each component is water: HYJ-1: PAC-LV: emulsified asphalt: polyethylene glycol: inorganic sodium bentonite: fluorocarbon surfactant: sodium carbonate = 100: 1: 2: 1: 2: 1.5 :1:3.

Embodiment 3

[0049] The formula is: fresh water 800g, HYJ-120g, PAC-LV4g, emulsified asphalt 8g, polyethylene glycol 16g, inorganic sodium bentonite 12g, fluorocarbon surfactant 8g, sodium carbonate 24g. The mass ratio of each component is water: HYJ-1: PAC-LV: emulsified asphalt: polyethylene glycol: inorganic sodium bentonite: fluorocarbon surfactant: sodium carbonate = 100: 2.5: 0.5: 1: 2: 1.5 :1:3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com