Preparation method and use of modified carbon black-LaMnO3 covalent composite material

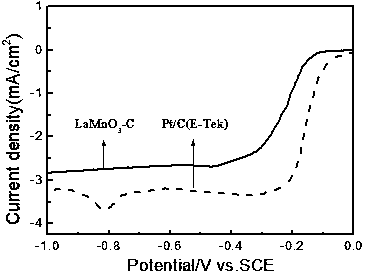

A composite material and modified carbon black technology, applied in chemical instruments and methods, physical/chemical process catalysts, structural parts, etc., can solve the problems of low activity, insufficient durability and high price, and achieve low process cost and convenient operation. , the effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

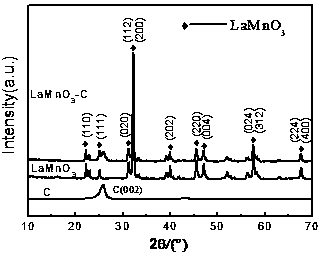

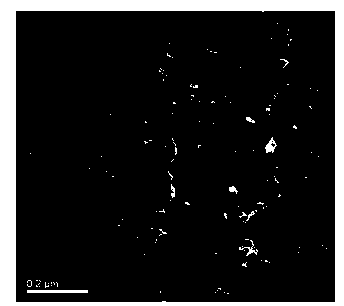

[0022] Preparation of modified carbon black-LaMnO with a composition ratio of 1:3 3 Covalent composites.

[0023] (1) Modified pretreatment of carbon carrier materials: using high-temperature graphitization + concentrated nitric acid + concentrated ammonia water for three consecutive steps of pretreatment; the first step is to put the carbon material (CB) into a self-made graphite tank and seal it, and then put the graphite The tank is sent to a large graphitization furnace at 2600°C under a protective gas argon atmosphere, kept for 1 hour and then cooled to room temperature with the furnace to obtain a highly graphitized carbon material (GCB); in the second step, weigh 10g of GCB and add it to a three-necked flask , Add 300ml of concentrated nitric acid and condense and reflux for 10h under the condition of 140°C oil bath. Cool the reaction solution, filter it, wash it with deionized water until it is neutral, and dry it in vacuum at 80°C; the third step is to add 300ml~500m...

Embodiment 2

[0028] Preparation of modified carbon black-LaMnO with a composition ratio of 2:3 3 covalent composite

[0029] (1) Modified pretreatment of carbon carrier materials: using high-temperature graphitization + concentrated nitric acid + concentrated ammonia water for three consecutive steps of pretreatment; the first step is to put the carbon material (CB) into a self-made graphite tank and seal it, and then put the graphite The tank is sent to a large graphitization furnace at 2600°C under a protective gas argon atmosphere, kept for 1 hour and then cooled to room temperature with the furnace to obtain a highly graphitized carbon material (GCB); in the second step, weigh 10g of GCB and add it to a three-necked flask , 300ml of concentrated nitric acid was condensed and refluxed for 10h in an oil bath at 140°C. Cool the reaction solution, filter it, wash it with deionized water until it is neutral, and dry it in vacuum at 80°C; the third step is to add 300ml~500ml of concentrated...

Embodiment 3

[0034] Preparation of modified carbon black-LaMnO with a composition ratio of 3:3 3 covalent composite

[0035] (1) Modified pretreatment of carbon carrier materials: using high-temperature graphitization + concentrated nitric acid + concentrated ammonia water for three consecutive steps of pretreatment; the first step is to put the carbon material (CB) into a self-made graphite tank and seal it, and then put the graphite The tank is sent to a large graphitization furnace at 2600°C under a protective gas argon atmosphere, kept for 1 hour, and then cooled to room temperature with the furnace to obtain a highly graphitized carbon material (GCB for short); the second step is to weigh 10g of GCB and add it to a three-necked flask In, add 300ml of concentrated nitric acid and condense and reflux for 10h under the condition of 140°C oil bath. Cool the reaction solution, filter it, wash it with deionized water until it is neutral, and dry it in vacuum at 80°C; the third step is to a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com