A LED light source module with efficient heat dissipation

A technology of LED light source and module, which is applied in the direction of light source, electric light source, lighting and heating equipment, etc. It can solve the problems of high-power LED light source damage, large LED light source light attenuation, energy waste, etc., and achieve good oxidation resistance and self-efficacy Clean performance, improve light reflection efficiency, enhance the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

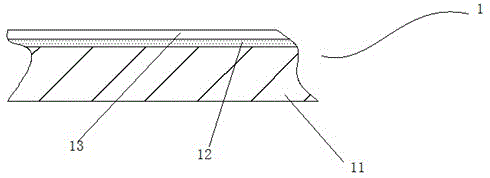

[0038] This embodiment provides a titanium oxide layer that can be used as a reflective layer for LED products, and its raw materials include 35 parts by weight of rutile phase titanium oxide, 3 parts of anatase nano-titanium oxide, and 4 parts of hexadecyltrimethylammonium chloride. part, 0.8 part of silane coupling agent and 45 parts of fluorocarbon base material; the particle size of the anatase nano-titanium oxide is 48nm; the particle size of the rutile phase titanium oxide is 0.5 μm; the preparation method of the titanium oxide layer In order to mix rutile phase titanium oxide, anatase nano titanium oxide, cetyltrimethylammonium chloride, silane coupling agent and fluorocarbon base material, heat it to 50°C, keep it for 25 minutes, and coat it on surface of the silver layer, and dried at a temperature of 40° C. for 100 minutes; the fluorocarbon base material refers to a coating with a fluorocarbon resin as a film.

Embodiment 2

[0040] This embodiment provides a titanium oxide layer that can be used as the reflective layer of LED products, and its raw materials include 30 parts of rutile phase titanium oxide, 5 parts of anatase nano-titanium oxide, and 5 parts of cetyltrimethylammonium chloride by weight. 2 parts, 2 parts of silane coupling agent and 40 parts of fluorocarbon base material; the particle size of the anatase nano-titanium oxide is 50nm; the particle size of the rutile phase titanium oxide is 0.1 μm; the preparation method of the titanium oxide layer In order to mix rutile phase titanium oxide, anatase nano titanium oxide, cetyltrimethylammonium chloride, silane coupling agent and fluorocarbon base material, heat it to 60°C, keep it for 20 minutes, and then coat it on The surface of the silver layer is dried at a temperature of 50° C. for 60 minutes; the fluorocarbon base material refers to a coating with a fluorocarbon resin as a film.

Embodiment 3

[0042] This embodiment provides an insulating layer of an LED product, which is made of thermally conductive and anti-aging PP material; the thermally conductive and anti-aging PP material refers to a PP material made of the following raw materials in parts by weight

[0043] PP45 copies;

[0044] 3 parts of mesoporous alumina fiber;

[0045] 0.5 parts of polyacrylamide;

[0046] 0.2 parts of carbon black;

[0047] Antioxidant 1680.5 parts;

[0048] 20 copies of POE grafting;

[0049] 2 parts deionized water.

[0050] The above-mentioned PP material can be prepared by any blending method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com