Method for assessing lithium ion battery safety through forced internal short circuit

A lithium-ion battery, safety performance evaluation technology, applied in the direction of secondary battery repair/maintenance, measurement of electricity, measurement of electrical variables, etc., can solve the problems of increased experiment contingency, poor reproducibility, and acupuncture experiments not included

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

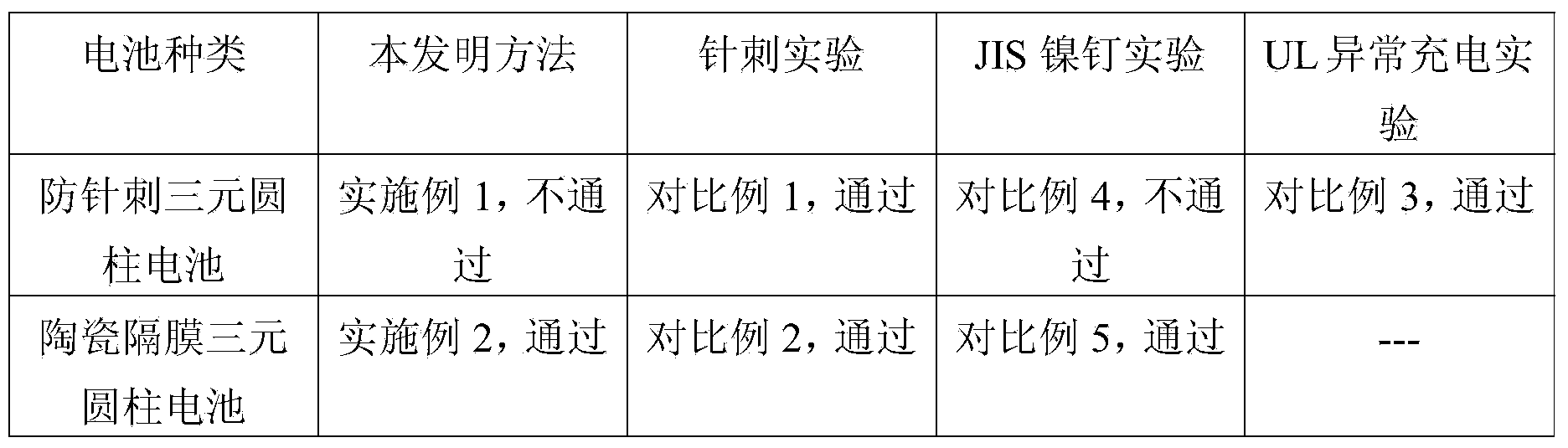

Embodiment 1

[0040] Take 4pcs anti-acupuncture ternary cylindrical batteries, charge them at 1C4.2V constant current and constant voltage until the cut-off current is 0.01C, then move the batteries to a dry room with a temperature of 23+ / -2°C and a dew point lower than -30°C, and use an electric drill to Open a small hole with a diameter of 1.0mm in the air chamber of the battery, stick the tape to the hole, remove it from the drying room, charge it with a constant current of 1C10V, and end when one of the following phenomena occurs: the temperature of the battery drops to about 10°C lower than the peak value or occurs Explosion and fire (the charging time does not exceed 8h).

[0041] Result: All 4 batteries exploded and failed.

Embodiment 2

[0043]Take 4pcs ceramic diaphragm ternary cylindrical battery, charge it at 1C4.2V constant current and constant voltage to the cut-off current of 0.01C, then move the battery to a dry room with a temperature of 23+ / -2°C and a dew point lower than -30°C, and use an electric drill to clean the battery Open a small hole with a diameter of 1.0mm in the air chamber, stick the tape to the hole, remove it from the drying room, charge it with a constant current of 1C10V, and end when one of the following phenomena occurs: the temperature of the battery drops to about 10°C lower than the peak value or an explosion occurs Fire (charging time does not exceed 8h).

[0044] Result: None of the 4 batteries burned or exploded, and passed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com