Preparation method of membrane electrode of alkaline anion-exchange membrane fuel cell

An anion exchange membrane, fuel cell membrane technology, applied in the direction of aqueous electrolyte fuel cells, fuel cells, battery electrodes, etc., can solve the problem that the performance is difficult to meet the requirements of large-scale commercialization, and achieve the enhancement of anion conductivity, inhibition of peeling, The effect of reducing the interface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

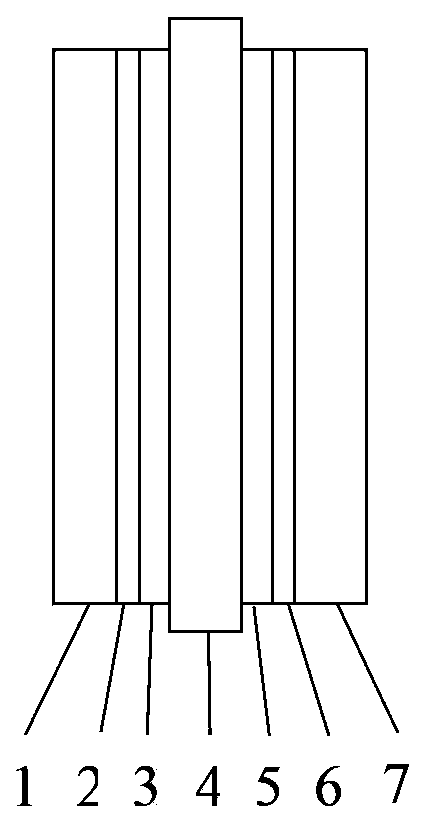

[0037] The structure of the membrane electrode is as figure 1 shown.

[0038] Membrane electrodes are prepared by the following process:

[0039] Weigh 1 gram of commercial 5% Tokuyama anion exchange resin AS-4, add 5mL of isopropanol to seal and dissolve to make anion exchange resin solution;

[0040] Add Pt / C to the above-mentioned anion exchange resin solution and ultrasonically disperse for 1 hour to form a cathode and anode catalyst layer precursor slurry with a mass ratio of electrocatalyst and resin of 1:10;

[0041] The above catalytic layer precursor slurry was sprayed on both sides of the Tokuyama anion exchange membrane with a thickness of 28 μm, and the catalyst coated electrode was obtained after the solvent evaporated; the loading of Pt was 0.4 mgcm -2 ;

[0042] Place activated carbon powder XC-72 and PTFE solution in ethanol with a mass ratio of 1:5, and ultrasonically disperse for 0.5 hours to form a uniform cathode microporous layer precursor slurry;

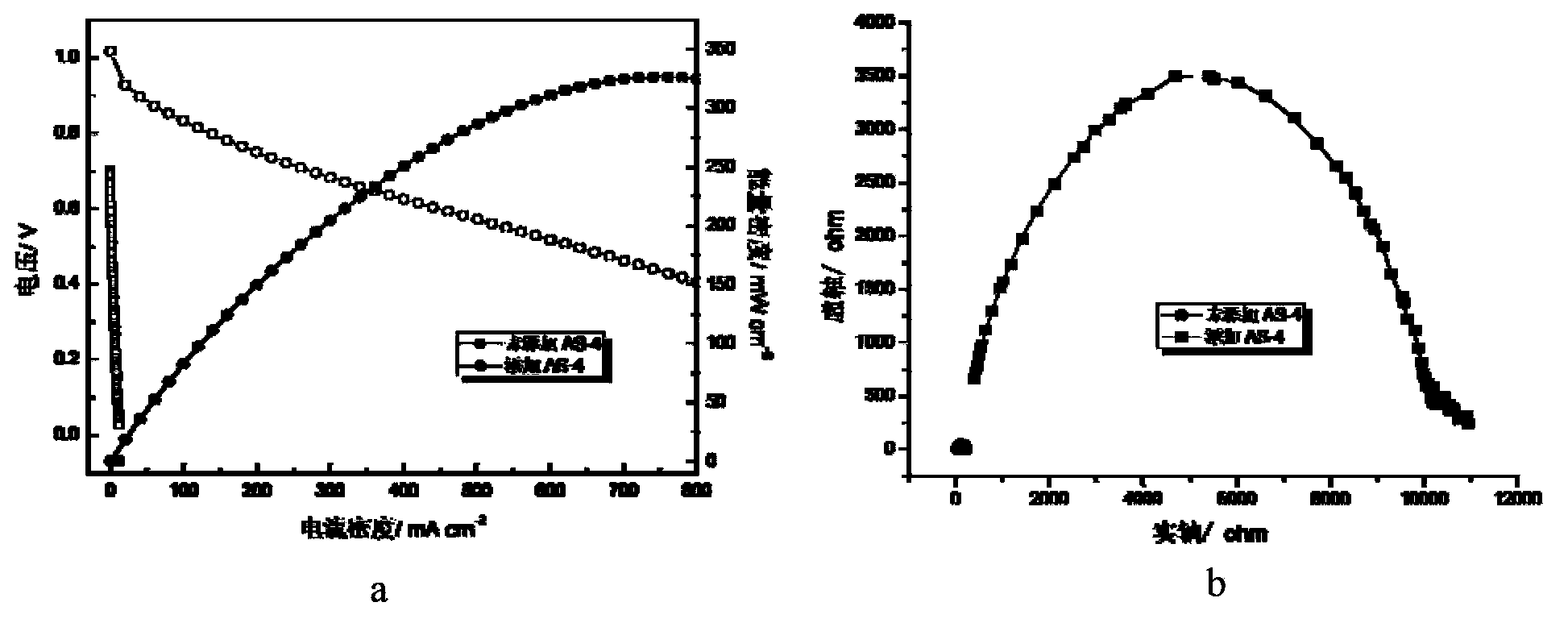

[0...

Embodiment 2

[0051] The difference from Example 1 is that the anion exchange membrane is passed through 0.05mgcm -2 The AS-4 modified A201, the polarization curve and power density curve of the battery are as follows image 3 As shown, the internal resistance of the battery is 26mohm, the open circuit voltage of the battery is 1.03V, and the peak power density of the battery is 334mWcm -2 .

Embodiment 3

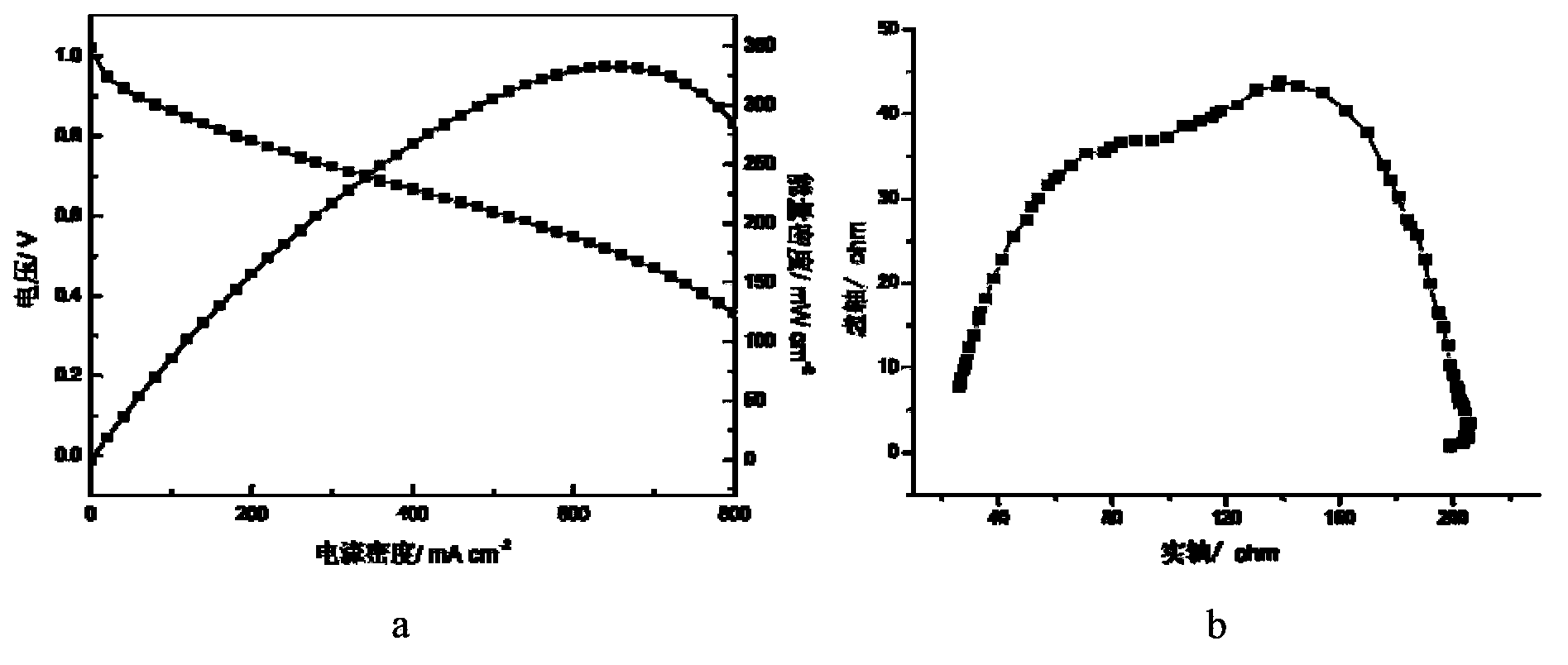

[0053] The difference with Example 1 is that the dispersion solvent used for the anion exchange resin is n-propanol, and the polarization curve and power density curve of the battery are as follows Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Peak power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com