A kind of sodium alginate microcapsules used in microwave hyperthermia technology for tumors and its preparation method and application

A technology of sodium alginate and microwave hyperthermia, which is used in microcapsules, capsule delivery, anti-tumor drugs, etc., can solve problems such as insufficient development and application, insufficient research on microwave hyperthermia, and difficulty in material selection. The effect of good clinical application value, improving diagnosis and treatment efficiency, and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

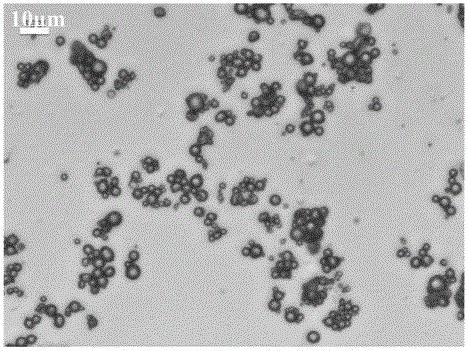

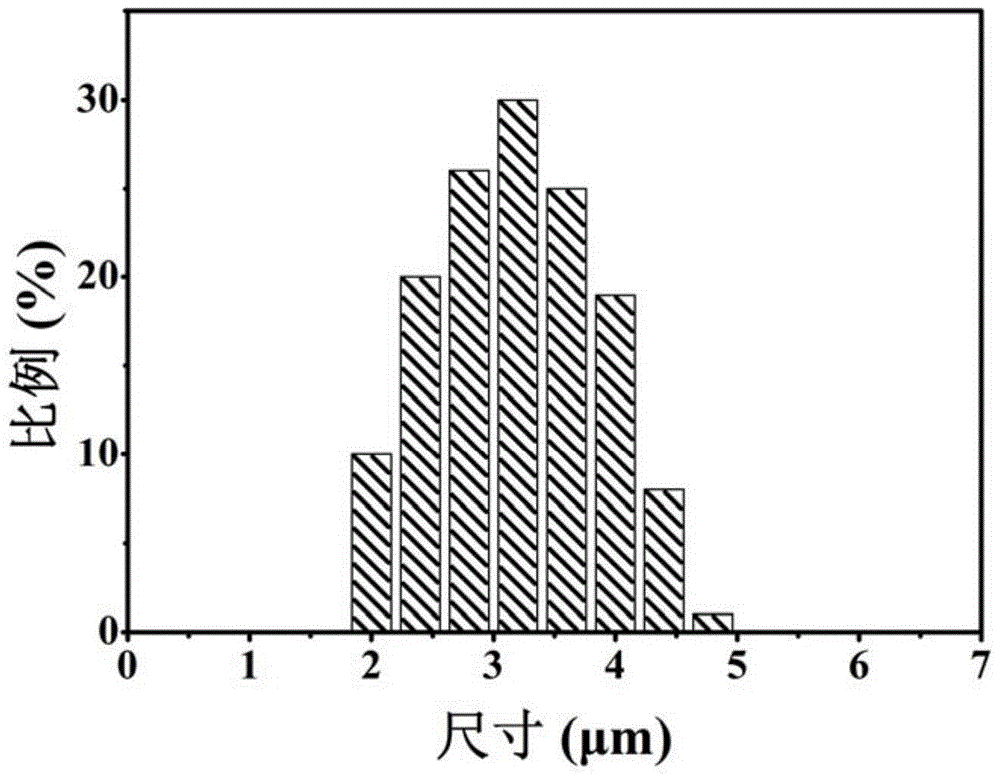

Image

Examples

Embodiment 1

[0046] (1) Prepare core material solution:

[0047] Stir and dissolve sodium alginate in deionized water to obtain a 1wt% sodium alginate solution, add sodium chloride to the sodium alginate solution as a core material, the mass ratio of sodium chloride to sodium alginate is 1:10, and stir and disperse evenly ;

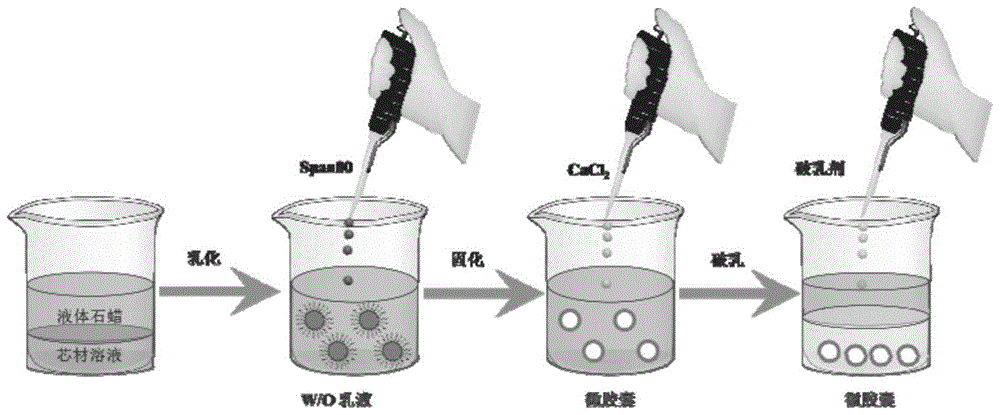

[0048] (2) emulsification step to form W / O emulsion:

[0049] Get the mixed solution of sodium alginate and sodium chloride obtained in step (1) into the conical flask, add liquid paraffin and emulsifier successively, the volume ratio of water phase to oil phase is 1:10, and the emulsifier used is Span80, and the emulsifier The volume fraction of 0.05%, magnetic stirring for 30 minutes to obtain a homogeneous milky white W / O emulsion;

[0050] (3) Microcapsule wall solidification step:

[0051] In the W / O emulsion obtained in step (2), calcium chloride was added as a solidifying agent, and magnetic stirring was performed for 30 minutes to form stable microcapsule w...

Embodiment 2

[0057] (1) Prepare core material solution:

[0058] Stir and dissolve sodium alginate in deionized water to obtain a 10wt% sodium alginate solution, add potassium chloride to the sodium alginate solution as a core material, the mass ratio of potassium chloride to sodium alginate is 1:5, and stir and disperse evenly ;

[0059] (2) emulsification step to form W / O emulsion:

[0060] Get the mixed solution of sodium alginate and potassium chloride obtained in step (1) into the conical flask, add liquid paraffin and emulsifier successively, the volume ratio of water phase and oil phase is 1:5, and the emulsifier used is Span80, emulsification The volume fraction of the agent was 0.5%, and the magnetic stirring was performed for 30 minutes to obtain a homogeneous milky white W / O emulsion;

[0061] (3) Microcapsule wall solidification step:

[0062] In the W / O emulsion obtained in step (2), calcium chloride was added as a solidifying agent, and magnetic stirring was performed for ...

Embodiment 3

[0068] (1) Prepare core material solution:

[0069] Stir and dissolve sodium alginate in deionized water to obtain a 5wt% sodium alginate solution, add ammonium chloride to the sodium alginate solution as a core material, the mass ratio of ammonium chloride to sodium alginate is 1:10, and stir and disperse evenly ;

[0070] (2) emulsification step to form W / O emulsion:

[0071] Get the mixed solution of sodium alginate and ammonium chloride obtained in step (1) into the conical flask, add liquid paraffin and emulsifier successively, the volume ratio of water phase and oil phase is 1:1, and the emulsifier used is Span80, and the emulsifier is The volume fraction of the agent was 0.1%, and the magnetic stirring was performed for 30 minutes to obtain a homogeneous milky white W / O emulsion;

[0072] (3) Microcapsule wall solidification step:

[0073] In the W / O emulsion obtained in step (2), calcium chloride was added as a solidifying agent, and magnetic stirring was performed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com