Unsaturated-acid modified nano composite polyester resin material and preparation method thereof

A polyester resin and nano-composite technology, applied in the field of resin composite materials, can solve problems such as difficulty in exerting the function of nano-materials, improving resin performance, and affecting the production of unsaturated polyester, so as to facilitate industrial production and improve mechanical properties and heat resistance, and the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

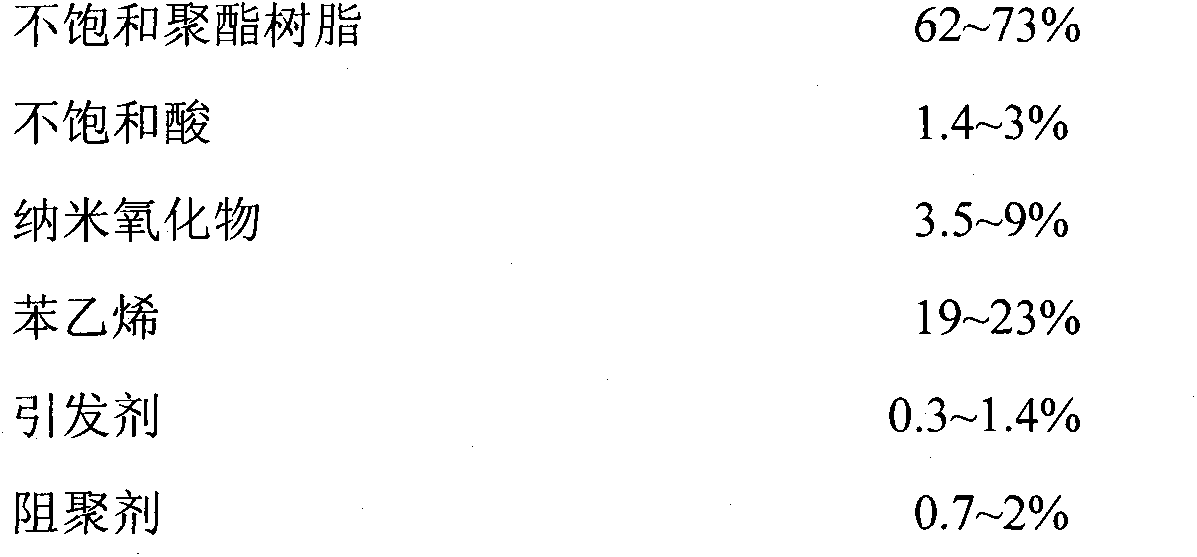

[0027] A kind of unsaturated acid modified nano-composite polyester resin material and its mass percent are:

[0028]

[0029] Wherein: the unsaturated acid is oleic acid; the nano-oxide is nano-silica; the initiator is cyclohexanone peroxide; and the polymerization inhibitor is hydroquinone.

[0030] The concrete steps of a kind of preparation method of unsaturated acid modified nano-composite polyester resin material are as follows:

[0031] (1) Preparation of unsaturated acid grafted nano oxides

[0032] According to the ratio of nano oxide mass (g): toluene volume (ml): the ratio of unsaturated acid volume (ml) is 1: 50: 0.095, the unsaturated acid is first added to the toluene, and then the nano oxide is added. The modification reaction was carried out on the nano-oxide for 4 hours under the condition of stirring at 90°C. Then the mixed solution after the modification reaction was naturally cooled to room temperature, then transferred to a centrifuge for centrifugati...

Embodiment 2

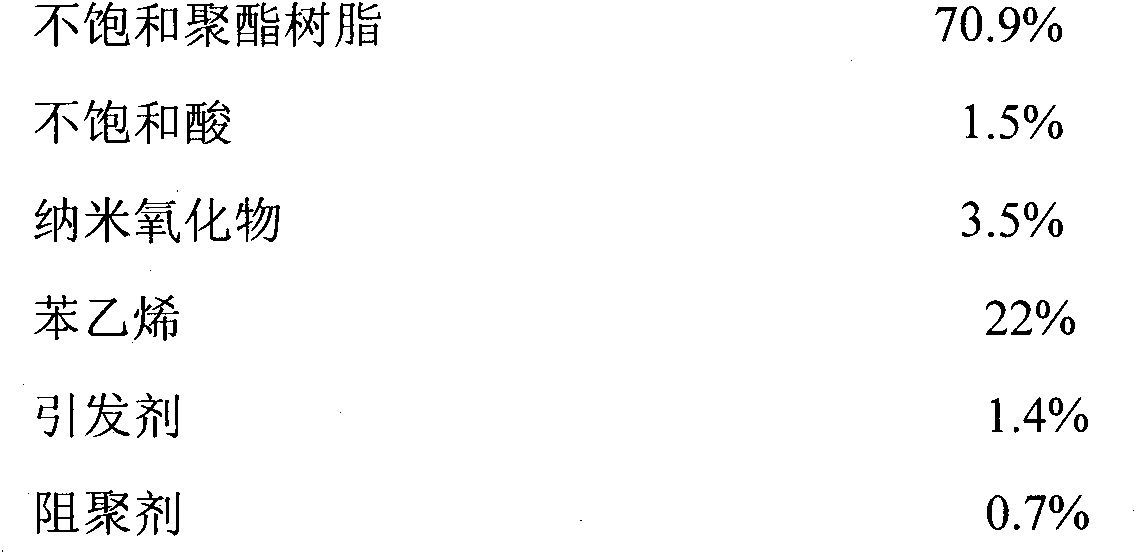

[0039] A kind of unsaturated acid modified nano-composite polyester resin material and its mass percent are:

[0040]

[0041] Wherein: the unsaturated acid is linoleic acid; the nano-oxide is zinc oxide; the initiator is methyl ethyl ketone peroxide; and the polymerization inhibitor is methyl hydroquinone.

[0042] A kind of preparation method of unsaturated acid modified nanometer composite polyester resin material, with embodiment 1, wherein:

[0043] In step (1), the ratio of nano-oxide mass (g): toluene volume (ml): unsaturated acid volume (ml) is 1: 46: 0.17, the temperature during modification is 40 ° C, the reaction is carried out for 5 hours, centrifuged The ratio of precipitate mass (g): absolute ethanol volume (ml) is 1:12, and the precipitate is washed three times after the first wash. Soxhlet extraction was carried out for 10 hours according to the precipitate mass (g) after washing: the volume of absolute ethanol (ml) was 1:63, the baking temperature was 150°...

Embodiment 3

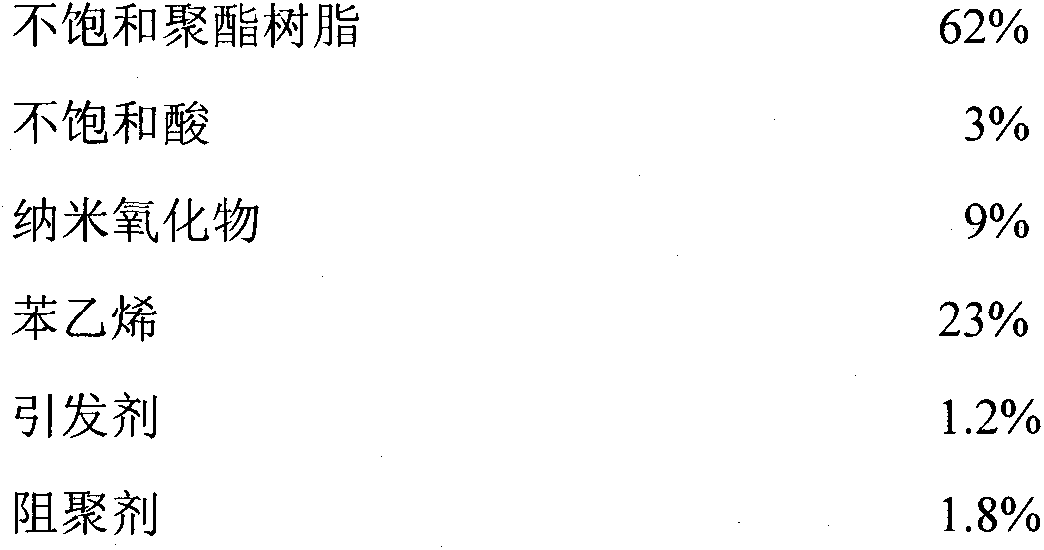

[0047] A kind of unsaturated acid modified nano-composite polyester resin material and its mass percent are:

[0048]

[0049]

[0050] Wherein: the unsaturated acid is linolenic acid; the nano-oxide is nano-titanium dioxide; the initiator is tert-butyl peroxybenzoate; and the polymerization inhibitor is p-hydroxyanisole.

[0051] A kind of preparation method of unsaturated acid modified nanometer composite polyester resin material, with embodiment 1, wherein:

[0052] In step (1), the ratio of nano-oxide mass (g): toluene volume (ml): unsaturated acid volume (ml) is 1: 70: 0.055, the temperature during modification is 110 ° C, the reaction is carried out for 6 hours, centrifuged and precipitated The ratio of mass (g): absolute ethanol volume (ml) is 1:25, and the precipitation is washed 4 times after the first wash. Soxhlet extraction was carried out for 24 hours according to the weight of the precipitate after washing (g): the volume of absolute ethanol (ml) was 1:89,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Unnotched impact strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com