Emulsified cutting fluid, cutting diluent and preparation and application methods thereof

A cutting fluid and raw material technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of rust prevention performance decline, metal surface corrosion, working fluid stratification, etc., to achieve good rust prevention performance, strong biological stability, prolonged The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

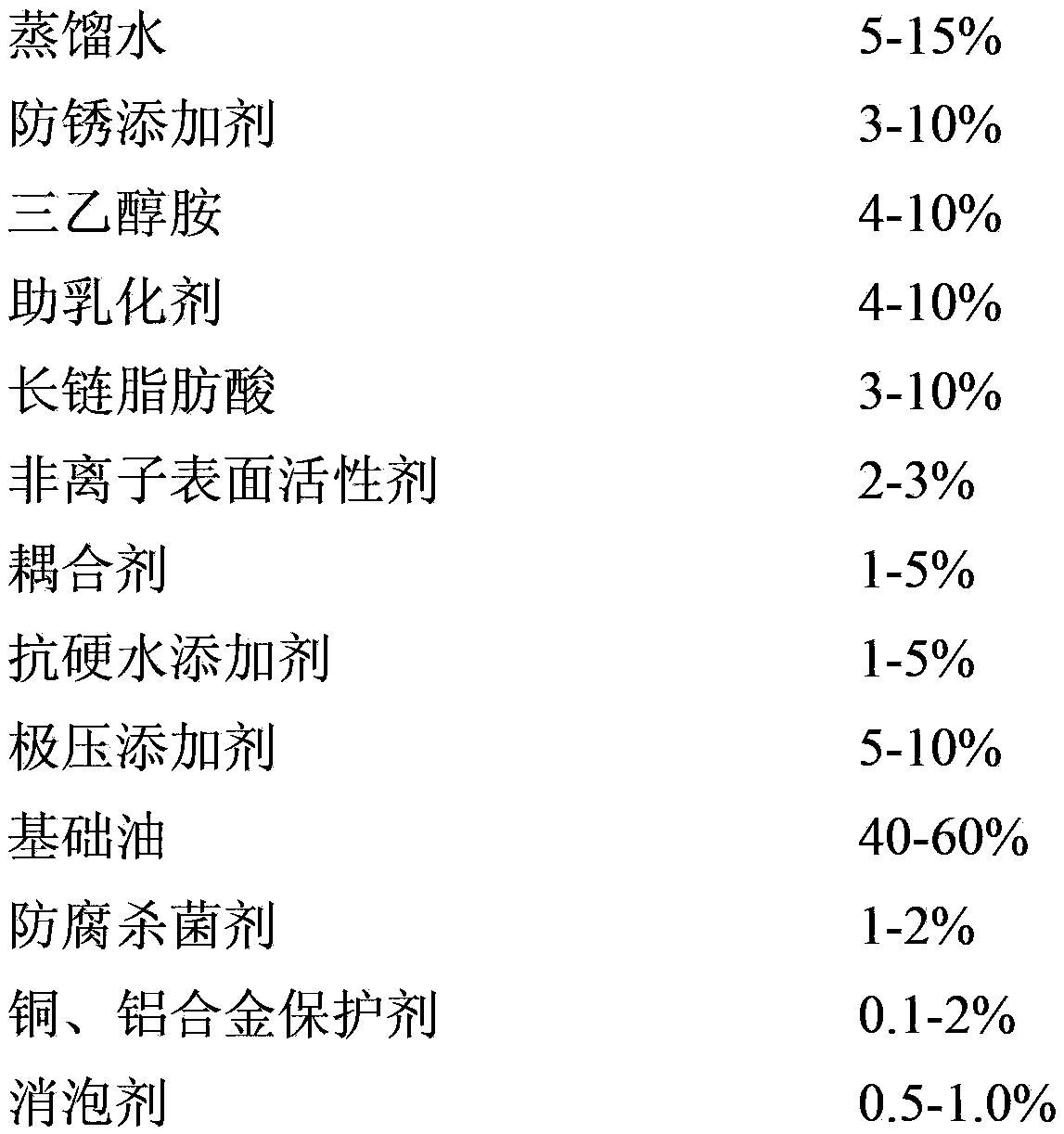

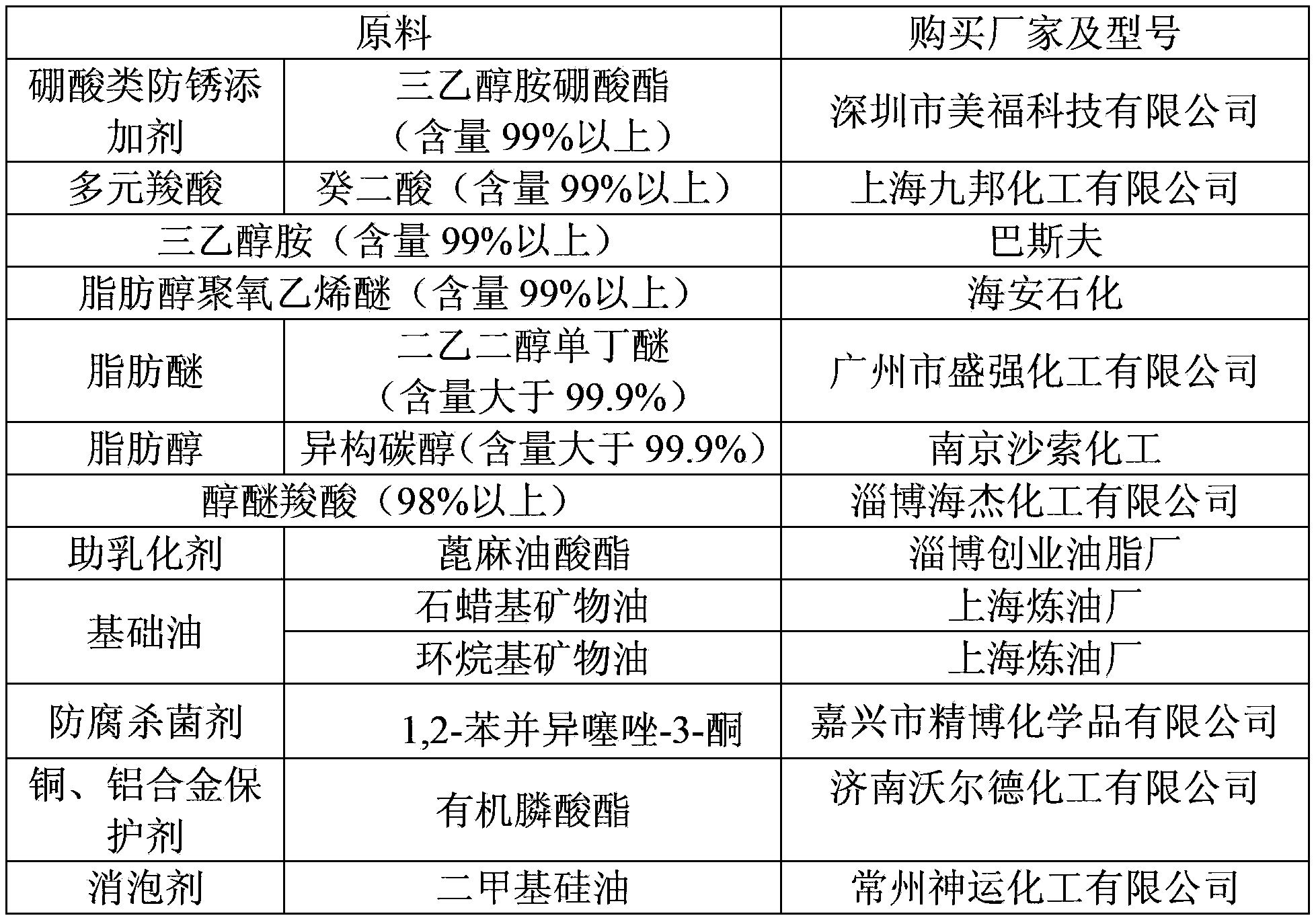

[0035] raw material:

[0036]

[0037]

[0038] Its preparation method is:

[0039] (1) Mix and stir distilled water, triethanolamine, and anti-rust additives, and heat to 80°C to obtain a mixed solution after the raw materials are completely dissolved;

[0040] (2) After cooling the above mixed solution to 60°C, add co-emulsifier, long-chain fatty acid, non-ionic surfactant, coupling agent, anti-hard water additive, extreme pressure additive, base oil, antiseptic and bactericide, copper, aluminum Alloy protective agent and defoamer, stir until the liquid is uniform and transparent.

Embodiment 2

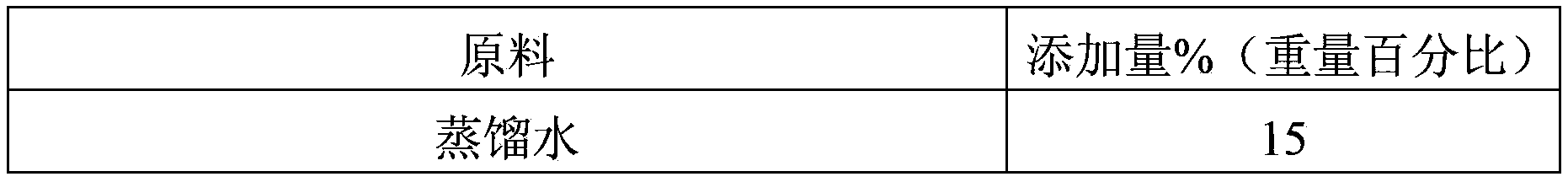

[0042] raw material:

[0043]

[0044]

[0045] Its preparation method is:

[0046] (1) Mix and stir distilled water, triethanolamine, and anti-rust additives, and heat to 70°C to obtain a mixed solution after the raw materials are completely dissolved;

[0047](2) After cooling the above mixed solution to 40°C, add co-emulsifier, long-chain fatty acid, non-ionic surfactant, coupling agent, anti-hard water additive, extreme pressure additive, base oil, antiseptic and bactericide, copper, Aluminum alloy protective agent and defoamer, stir until the liquid is uniform and transparent.

Embodiment 3

[0049] raw material:

[0050]

[0051]

[0052] Its preparation method is:

[0053] (1) Mix and stir distilled water, triethanolamine, and anti-rust additives, and heat to 90°C to obtain a mixed solution after the raw materials are completely dissolved;

[0054] (2) After cooling the above mixed solution to 50°C, add co-emulsifier, long-chain fatty acid, non-ionic surfactant, coupling agent, anti-hard water additive, extreme pressure additive, base oil, antiseptic and bactericide, copper, aluminum Alloy protective agent and defoamer, stir until the liquid is uniform and transparent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com