Method for preparing gradient metal-containing three-dimensional network ceramic

A three-dimensional network and cermet technology, which is applied to the preparation of gradient metal-containing three-dimensional network ceramics and the field of preforms of network ceramics reinforced metal composite materials, can solve the problems of high cost, complex process, metal and ceramic cracks, etc. Mature technology to solve the effect of low interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Below with preparation nickel-containing 20wt% porous ceramic process, the present invention is described in detail:

[0041] Select the granulated 95 porcelain Al2O3 ceramic powder provided by China Aluminum Co., Ltd., the particle size is in the range of 0.1-0.5mm, the main composition: 2.5wt%SiO 2 , 2.0 wt % CaO, 0.5 wt % MgO, Al 2 o 3 Surplus, nickel powder, the purity of nickel powder is 99.96%, and average particle size is 40 μ m, and the dosage of various additives is shown in Table 1:

[0042] Table 1 Ceramic aggregates and additives

[0043]

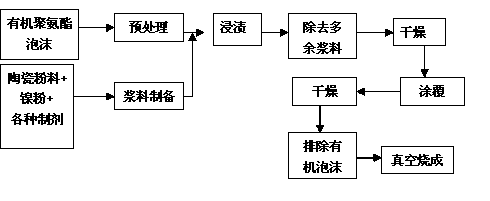

[0044] The specific steps and process conditions are as follows, see the flow chart figure 1 :

[0045] Step 1: Mix the powder

[0046] The selected metal powder is mechanically mixed with commercial ceramic powder to prepare mixed powders with different metal contents, wherein, in terms of mass fraction, the metal powder content is 20wt%;

[0047] Step 2: Ball Milling

[0048] The mixed powder mechanically m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com