White organic light-emitting diode and manufacturing method thereof

An electroluminescent device, organic technology, applied in the direction of organic semiconductor devices, electric solid devices, semiconductor/solid device manufacturing, etc., can solve the problems of high working current and low color rendering index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

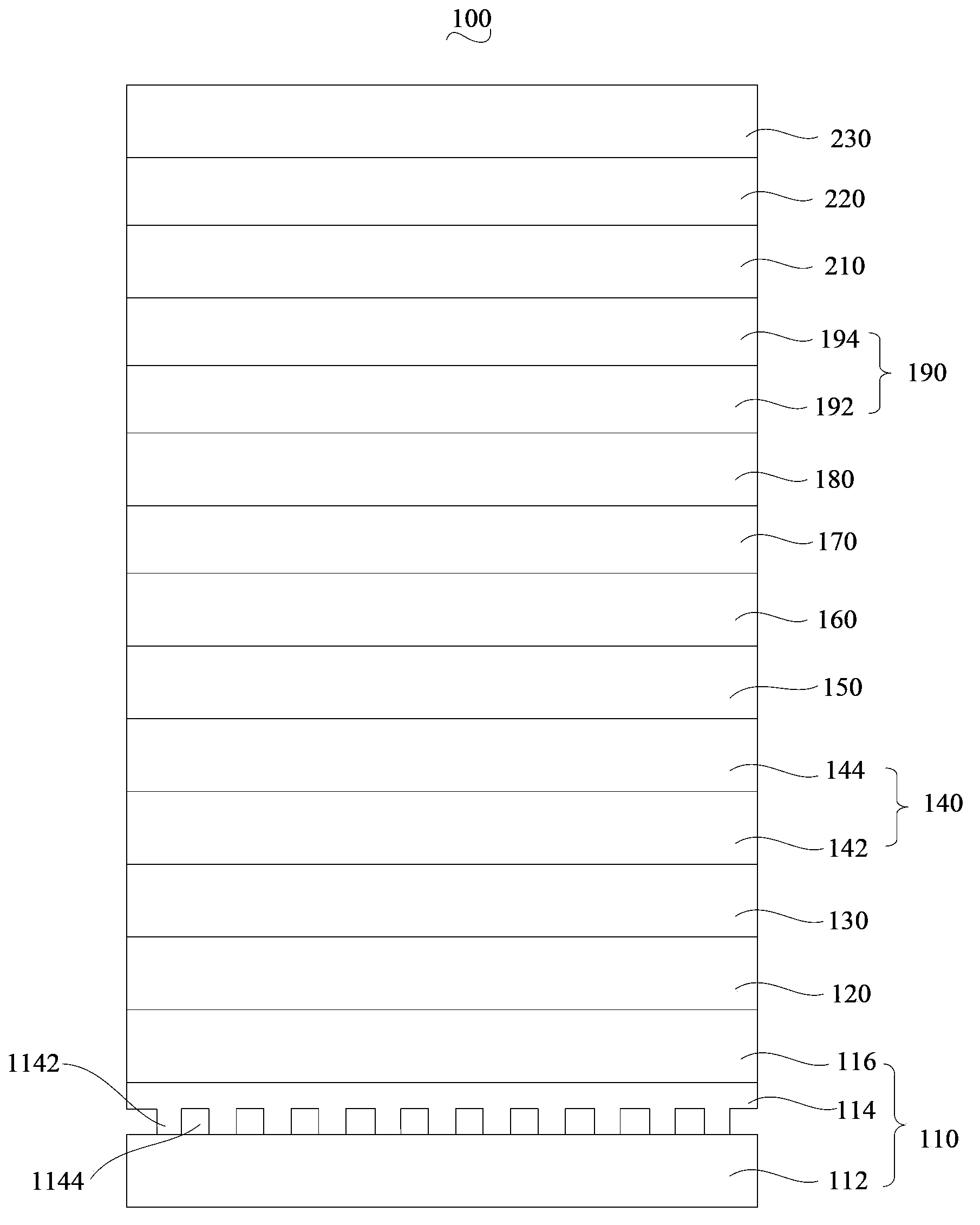

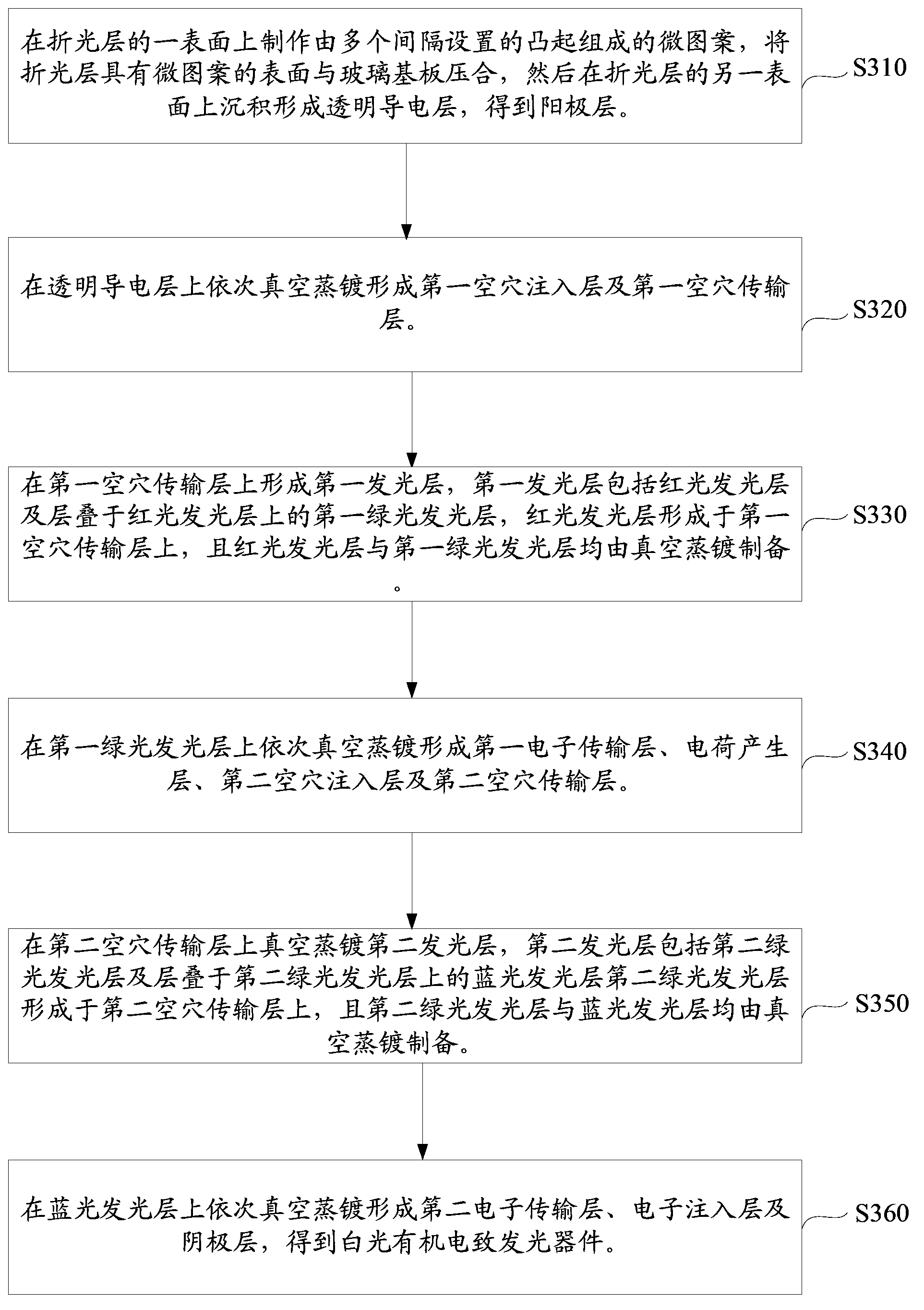

[0068] like figure 2 As shown, a method for preparing a white light organic electroluminescent device in one embodiment includes the following steps:

[0069] Step S310: On one surface of the refraction layer, a micropattern consisting of a plurality of protrusions arranged at intervals is made, and the surface of the refraction layer with the micropatterns is pressed against the glass substrate, and then deposited on the other surface of the refraction layer to form a transparent The conductive layer is used to obtain the anode layer, wherein a plurality of gaps are formed between the refraction layer and the glass substrate.

[0070] Preferably, before pressing the surface of the refraction layer with the micropattern on the glass substrate, it also includes the steps of sequentially cleaning and surface activating the glass substrate; the cleaning step is: sequentially wash the glass substrate with detergent, deionized water, Ultrasonic cleaning with acetone and ethanol, ...

Embodiment 1

[0093]The structure of the white light organic electroluminescence device of the present embodiment is: ITO / PU / ITO / NPB:MoO 3 / NPB / TCTA:Ir(MDQ) 2 (acac) / TCTA:Ir(ppy) 3 / Bphen / MoO 3 / NPB:MoO 3 / NPB / TCTA:Ir(ppy) 3 / CBP:Firpic:MoO 3 / Bphen / Bphen:Cs 2 CO 3 / Ag.

[0094] The preparation of the white light organic electroluminescent device of this embodiment is as follows:

[0095] (1) Clean the ITO glass substrate with a thickness of 100 nanometers sequentially with detergent, deionized water, acetone and ethanol ultrasonically, wash for 5 minutes each time, stop for 5 minutes, repeat 3 times respectively, and then dry it in an oven. After drying, the glass substrate is subjected to surface activation treatment; on one surface of the refraction layer, a micro-pattern consisting of a plurality of protrusions arranged at intervals is made. The width of each protrusion is 5 microns, and the height is 5 microns. The distance between the two protrusions is 5 microns; the surface...

Embodiment 2

[0102] The structure of the white light organic electroluminescence device of the present embodiment is: ITO / PU / AZO / TCTA:WO 3 / TCTA / mCP:PQIr / mCP:Ir(ppy) 2 (acac) / BCP / V 2 o 5 / TCTA:WO 3 / TCTA / mCP:Ir(ppy) 2 (acac) / mCP:FIr6:V 2 o 5 / BCP / BCP:CsF / Al.

[0103] The preparation of the white light organic electroluminescent device of this embodiment is as follows:

[0104](1) Clean the ITO glass substrate with a thickness of 100 nanometers sequentially with detergent, deionized water, acetone and ethanol ultrasonically, wash for 5 minutes each time, stop for 5 minutes, repeat 3 times respectively, and then dry it in an oven. After drying, the glass substrate is subjected to surface activation treatment; on one surface of the refraction layer, a micro-pattern consisting of a plurality of protrusions arranged at intervals is made, each protrusion has a width of 10 microns and a height of 10 microns, and two adjacent The distance between the two protrusions is 10 microns; the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Lumen efficiency | aaaaa | aaaaa |

| Lumen efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com