Valley fill circuit with protection function

A technology of protection function and valley filling circuit, applied in the field of rectification and filtering, can solve the problems of large differential mode conduction interference, decreased power factor of valley filling circuit, poor surge voltage absorption effect, etc. The effect of large factor and good protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

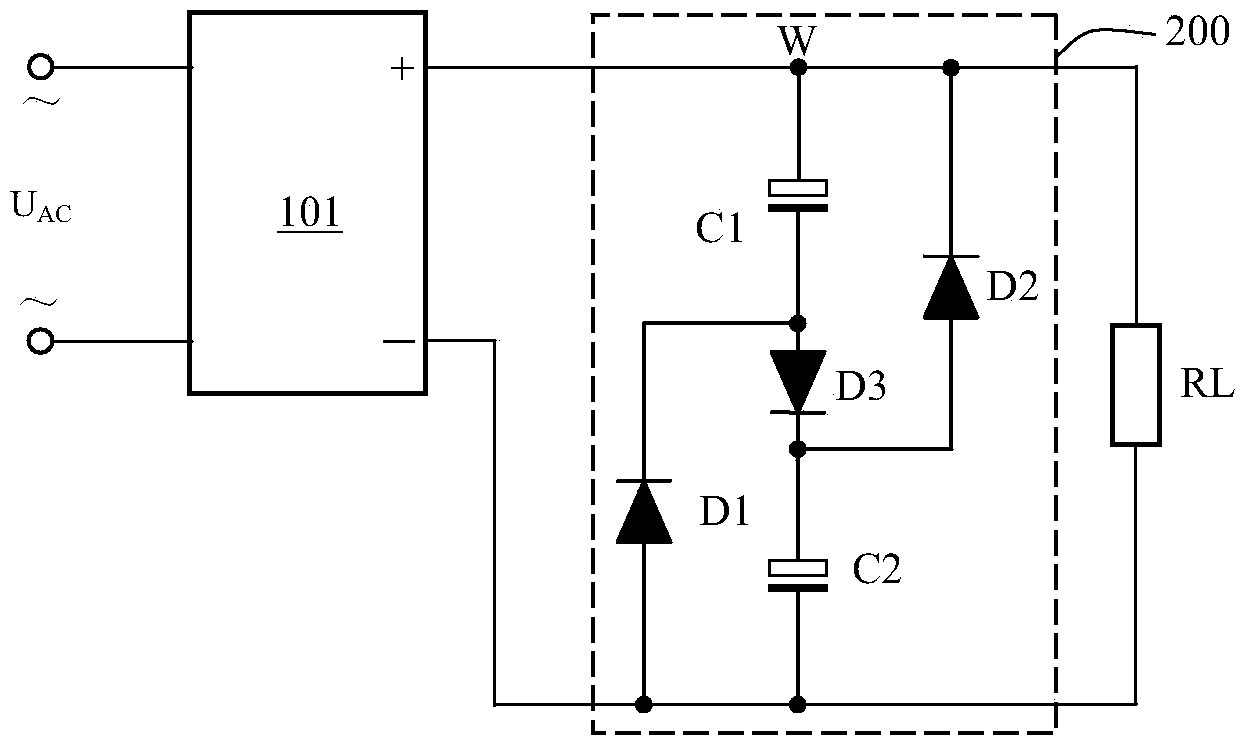

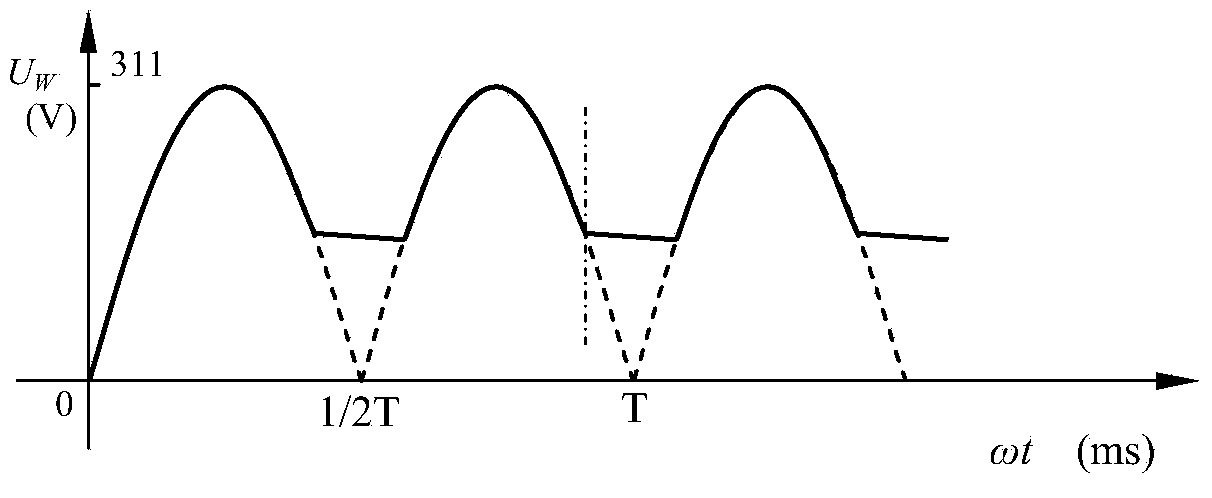

[0057] Figure 5 Shows the principle diagram of the valley filling circuit with protection function of the first embodiment, a valley filling circuit with protection function, which is used to directly connect the AC input U AC , Including valley filling circuit 201, and a rectifier circuit 202 with protection function set in the front stage of valley filling circuit, AC input U AC It has a first terminal 01 and a second terminal 02; connected to the rectifier circuit 202 with protection function, the rectifier circuit 202 with protection function includes two interchangeable input terminals, which are Figure 5 The two ends of the first varistor RV1, and the positive output terminal (V O+ The terminal connected to the second varistor RV2) and the negative output terminal (V O- The terminal connected to the second varistor RV2);

[0058] The valley filling circuit 201 includes a first capacitor C1 and a first diode D1. The anode of the first capacitor C1 is connected to the anode ...

no. 2 example

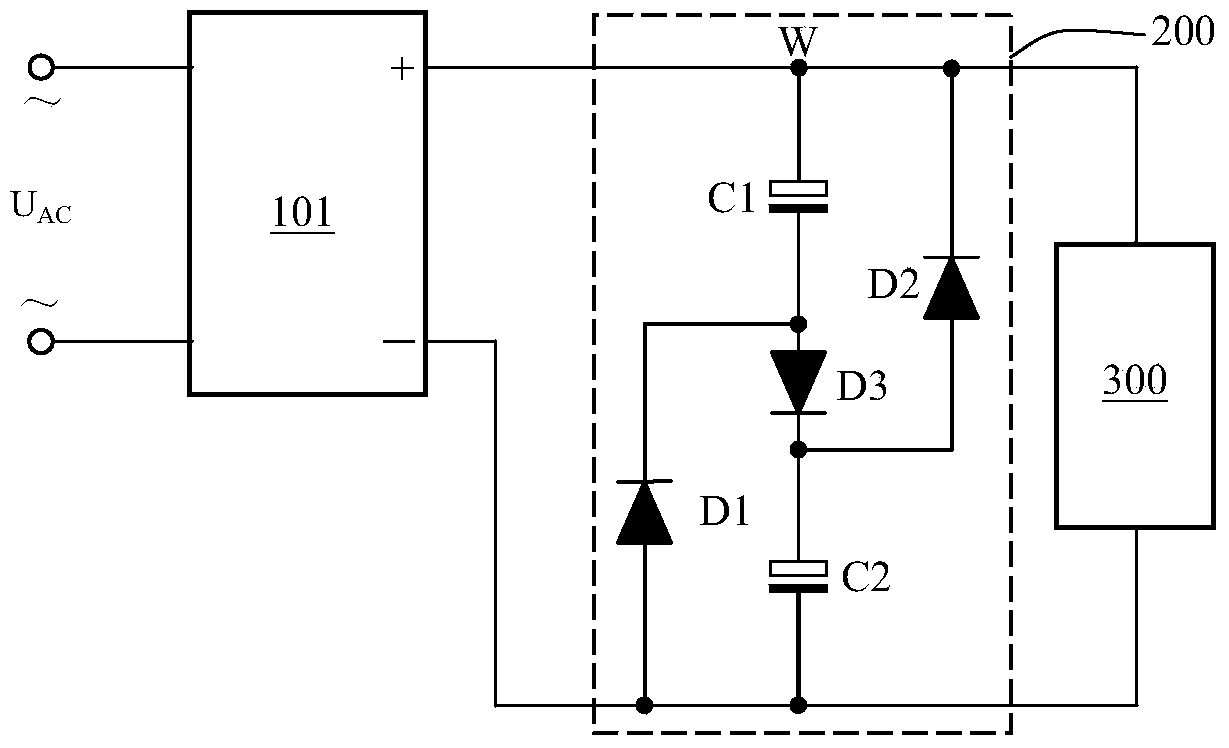

[0085] Figure 7 Shows the principle diagram of the valley filling circuit with protection function of the second embodiment, a valley filling circuit with protection function, which is used to directly connect the AC input U AC , Including valley filling circuit 201, and a rectifier circuit 202 with protection function set in the front stage of valley filling circuit, AC input U AC It has a first terminal 01 and a second terminal 02; connected to the rectifier circuit 202 with protection function, the rectifier circuit 202 with protection function includes two interchangeable input terminals, which are Figure 7 The two ends of the first varistor RV1, and the positive output terminal (V O+ The terminal connected to the second varistor RV2) and the negative output terminal (V O- The terminal connected to the second varistor RV2);

[0086] The circuit connection relationship of the valley filling circuit 201 is the same as that of the first embodiment, and will not be repeated here...

no. 3 example

[0091] Figure 8 Shows the principle diagram of the valley filling circuit with protection function of the third embodiment, a valley filling circuit with protection function, which is used to directly connect the AC input U AC , Including valley-filling circuit 201’, and a rectifier circuit 202 with protection function set in the front stage of valley-filling circuit, AC input U AC It has a first terminal 01 and a second terminal 02; connected to the rectifier circuit 202 with protection function, the rectifier circuit 202 with protection function includes two interchangeable input terminals, which are Figure 8 Both ends of the medium-voltage sensitive resistor RV1, and the positive output terminal (V O+ The terminal connected to the second varistor RV2) and the negative output terminal (V O- Terminal connected to varistor RV2);

[0092] The difference from the first and second embodiments is that the valley filling circuit 201' also includes a resistor R1, which is connected in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com