Detoxifying treatment method and device of tail gas containing H2S with low concentration

A treatment method and technology of treatment device, which are applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve problems such as no major breakthrough in environmental protection management, high resource consumption, high energy consumption, and weak toxic gas treatment. , to achieve the effect of high industrial utilization value, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

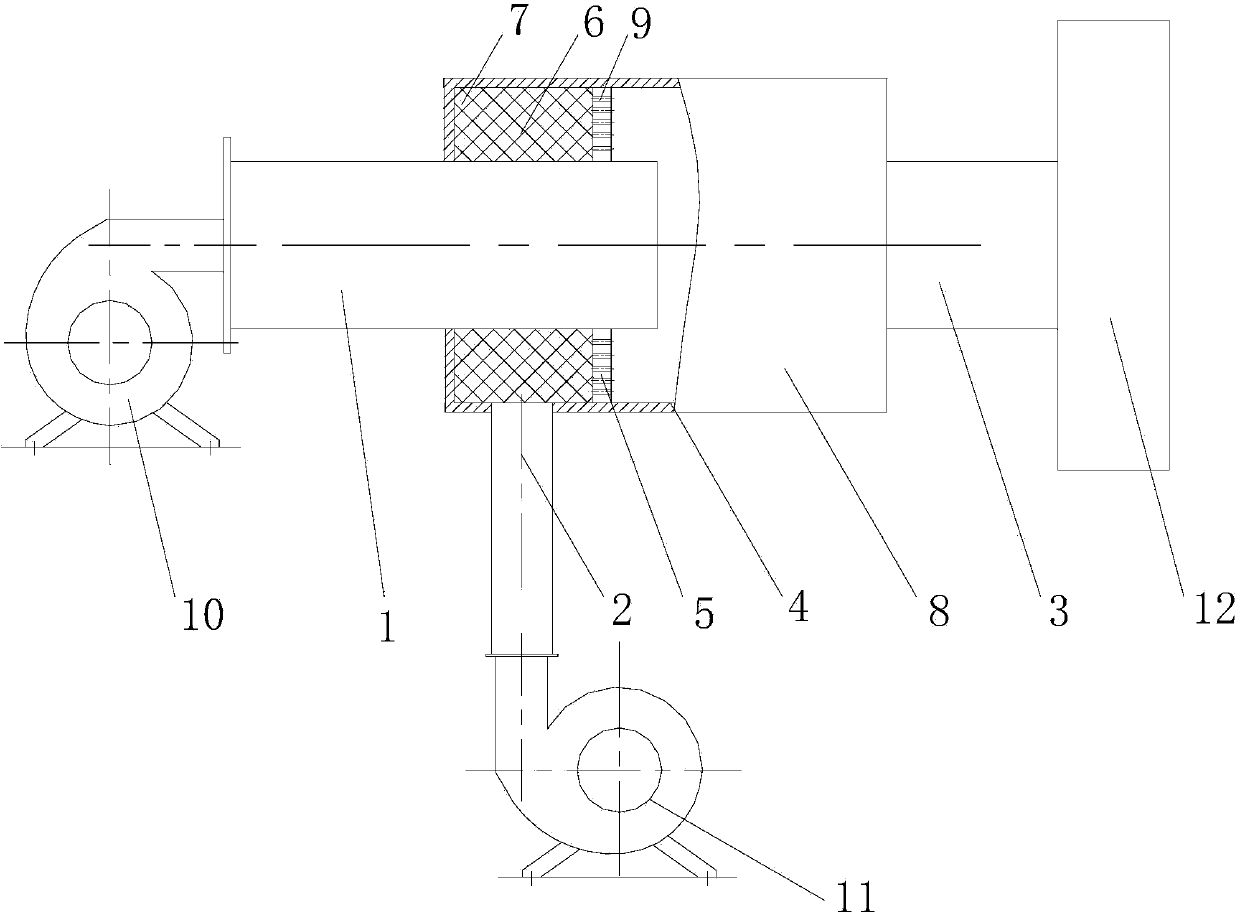

[0028] A kind of low concentration H of the present invention 2 Non-toxic treatment device for S tail gas, such as figure 1 As shown, it includes a catalyst mixer, a flue gas inlet pipe 1 (with an inner diameter of 300mm), an exhaust gas inlet pipe 2 and a mixer outlet pipe 3 (with an inner diameter of 300mm). The catalyst mixer includes a mixer body 4 , an orifice plate 5 and a catalyst net 6 . The orifice plate 5 is located in the inner cavity of the mixer body 4 and divides the inner cavity of the mixer body 4 into a first chamber 7 and a second chamber 8 . The orifice plate 5 is provided with a plurality of through holes 9 (8 mm in diameter, 6 mm to 10 mm are acceptable) for transferring the activated tail gas from the first chamber 7 to the second chamber 8 . One end of the mixer body 4 is provided with a flue gas inlet communicating with the first chamber 7, the side of the mixer body 4 is provided with an exhaust gas inlet communicating with the first chamber 7, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com