A production of stable isotopes 15 n's full cycle, double feed energy saving system

A stable isotope, energy-saving system technology, applied in the production field of high abundance 15N, can solve the problems of large consumption of raw material nitric acid, low nitric acid utilization rate, large waste acid treatment capacity, etc., to reduce storage and transportation risks and facilitate equipment selection. , the effect of reducing storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

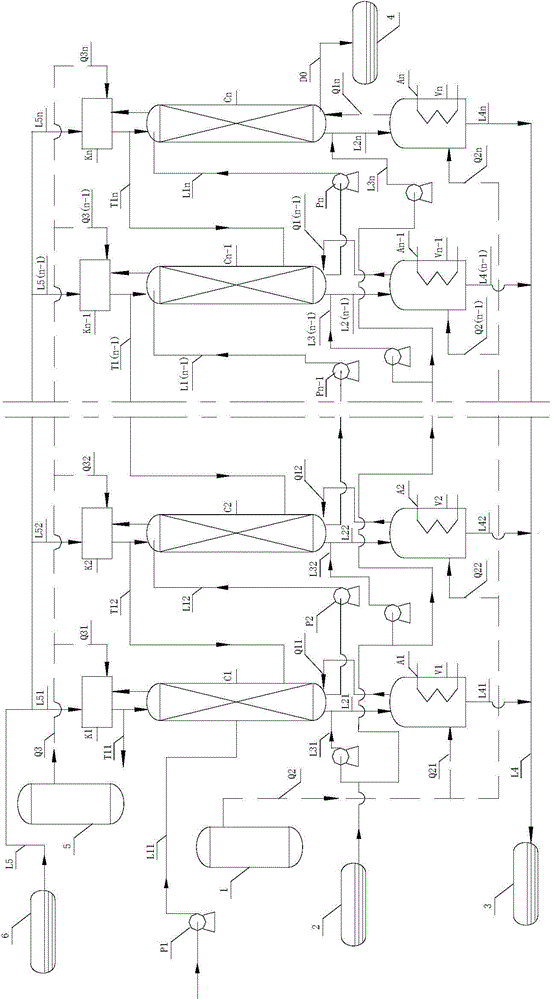

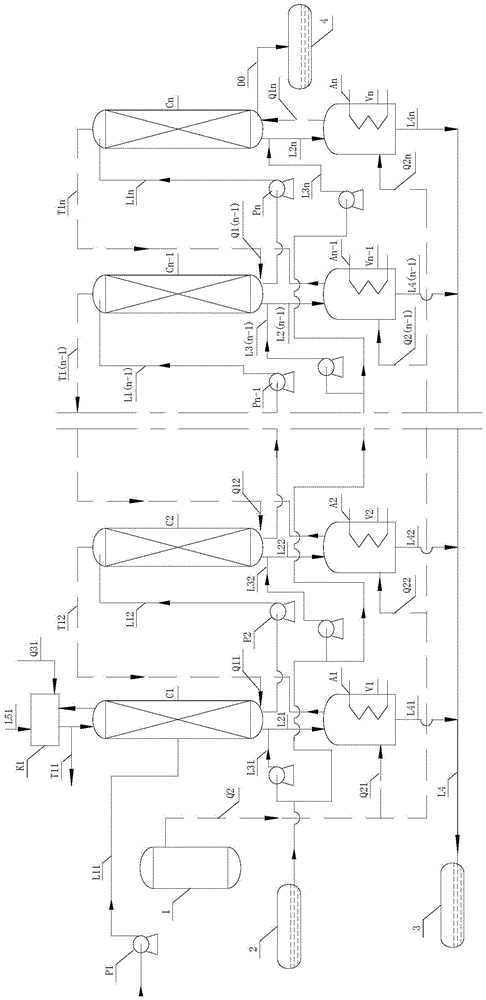

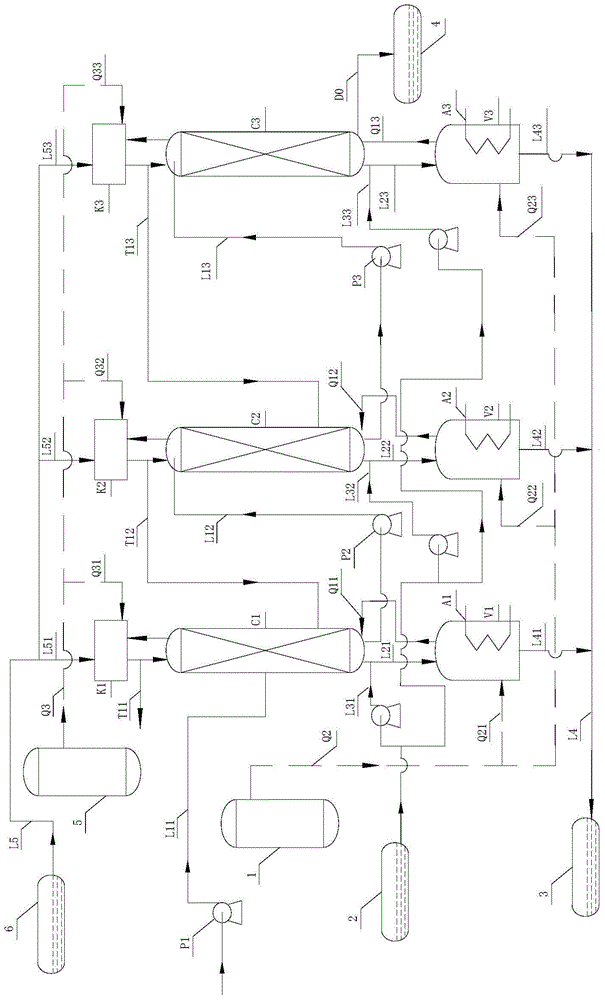

[0048] figure 1 It is a schematic diagram of a cascade production system composed of n-stage exchange towers in the present invention, and the system is a cascade device composed of n-stage horizontally connected exchange towers. In the cascade device of the present invention, the specific connection modes of the towers at all levels are described as follows.

[0049] refer to figure 1 Schematic diagram of the flow chart, the n-stage exchange tower is composed of mass transfer exchange tower C 1 ~C n , reaction reflux tower V 1 ~V n And the absorption tower K at the top of the tower 1 ~K n constitute. Among them, the reactant O in the absorption tower 2 From storage tank 5 through main pipe Q 3 Conveying, through branch Q 31 ~Q 3n Separately conveyed into the absorption tower K 1 ~K n Inside, reactant H 2 O from the storage tank 6 through the main pipe L 5 Conveying, through branch pipe L 51 ~ L 5 n are transported into the absorption tower K respectively 1 ~...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com