Carbon nano tube enhanced copper-based composite material and preparation method thereof

A copper-based composite material and carbon nanotube technology are applied in carbon nanotube-reinforced copper-based composite materials and their preparation, and in the field of copper-based composite materials, and can solve the potential safety hazards of strong bases and strong oxidants, complicated processes, and tannic acid structure. The problem of large molecular weight, etc., can improve the electrical friction and wear performance, strength and impact resistance, simple process and good reinforcement effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Add multi-walled carbon nanotubes to 10 μg / ml gallic acid aqueous solution, and disperse evenly, wherein the ratio of the weight of carbon nanotubes to the volume of gallic acid aqueous solution is 0.1g: 40ml; let stand for 24h, filter, and take the filter residue at 60 and dried under vacuum for 2 h at °C to obtain surface-modified carbon nanotubes.

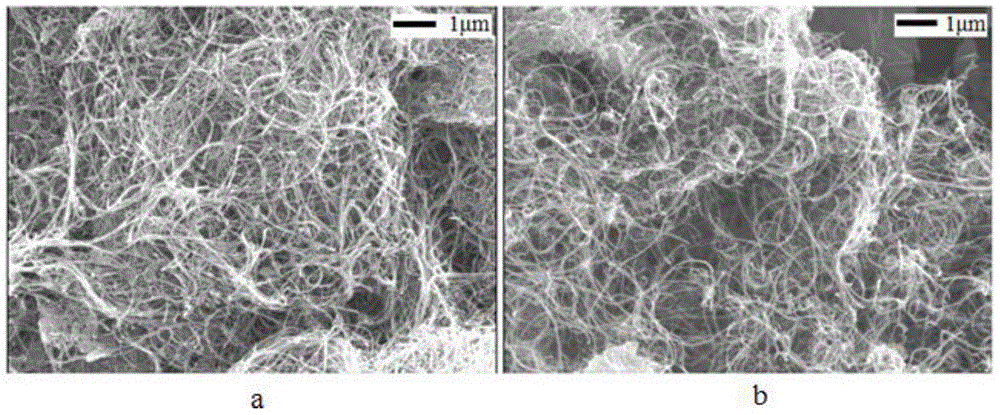

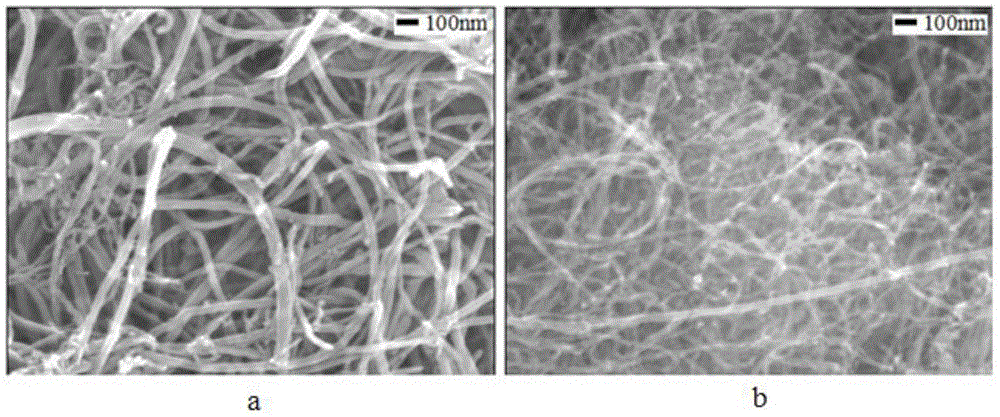

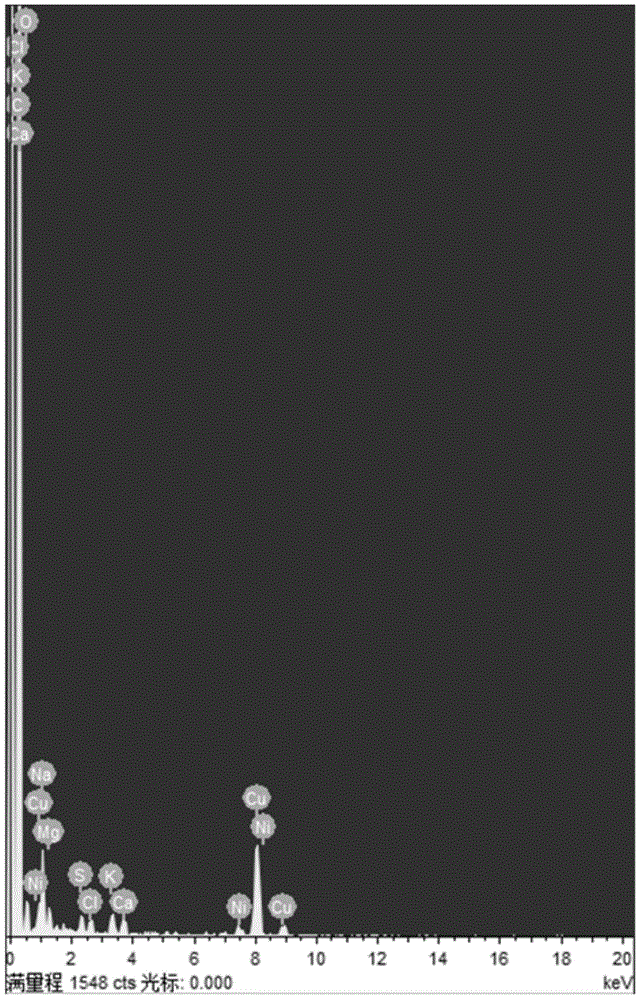

[0041] figure 1 Low magnification (×10000) SEM images of carbon nanotubes (CNTs) before and after treatment with aqueous gallic acid: a. SEM image without gallic acid aqueous solution treatment; b. SEM image after gallic acid aqueous solution treatment. figure 2 High magnification (×50000) SEM images of carbon nanotubes (CNTs) before and after treatment with gallic acid aqueous solution: a. SEM image without gallic acid aqueous solution treatment; b. SEM image after gallic acid aqueous solution treatment. from figure 1 and 2 It can be seen that the carbon nanotubes without gallic acid aqueous solution are agglomerated...

Embodiment 2

[0045] Add single-walled carbon nanotubes to 3 μg / ml gallic acid aqueous solution, and disperse evenly, wherein the ratio of the weight of carbon nanotubes to the volume of gallic acid aqueous solution is 0.5g: 60ml; let stand for 12h, filter, and take the filter residue at 70 °C for 1 h in vacuum to obtain surface-modified carbon nanotubes.

[0046] Evenly disperse 0.1 g of the surface-modified carbon nanotubes prepared in this example in 100 ml of deionized water. After standing for 3 days, the precipitation gradually increases under the action of gravity, but the carbon nanotubes still maintain a dispersed state without occurrence of reunion. It shows that the surface-modified carbon nanotubes prepared in Example 2 have excellent dispersibility.

Embodiment 3

[0048] Add multi-walled carbon nanotubes to 18 μg / ml gallic acid aqueous solution, and disperse evenly, wherein the ratio of the weight of carbon nanotubes to the volume of gallic acid aqueous solution is 0.05g: 20ml; let stand for 30h, filter, and take the filter residue at 80 and dried under vacuum for 3 h at °C to obtain surface-modified carbon nanotubes.

[0049] Evenly disperse 0.1 g of the surface-modified carbon nanotubes prepared in this example in 100 ml of deionized water. After standing for 2 days, the precipitation gradually increases under the action of gravity, but the carbon nanotubes still maintain a dispersed state without occurrence of reunion. It shows that the surface-modified carbon nanotubes prepared in Example 2 have excellent dispersibility.

[0050] From Examples 1 to 3, it can be seen that the surface-modified carbon nanotubes prepared in Example 1 gradually precipitated under the action of gravity after standing for 5 days, and the carbon nanotubes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com