Titanium pipe welding process of seawater lift pump system

A seawater lift pump and welding process technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of high difficulty, high requirements for welding process control, and easy generation of air holes, etc., and achieve great economic benefits and Social benefits, high-quality welding effects, and effects of avoiding air holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The titanium pipe welding process of the seawater lift pump system in this embodiment is characterized in that it includes the following steps:

[0027] (1) Choose a closed welding environment, the welding environment is clean and independent, the humidity of the air does not exceed 60%, the temperature is not lower than 15 ℃, and the influence of other air currents must be avoided during the welding process.

[0028] (2) Before the titanium tube is assembled, use a clean lint-free cloth with acetone to wipe off all scale, slag, oxides or other foreign metals on and near the weld, and titanium within 100mm of the weld ends. The inside and outside of the pipe are cleaned with acetone, and the welding wire to be used is also cleaned in the same way. During the above cleaning process, the operator wears white cotton gloves, and it is forbidden to directly touch the pipe fittings and welding materials with hands.

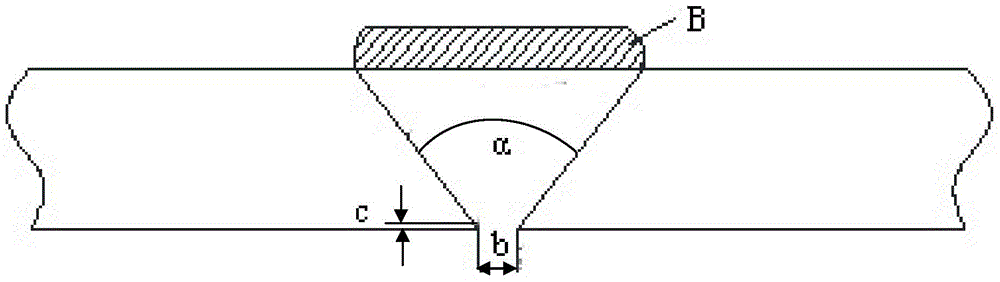

[0029] (3) Titanium tubes are butted with V-shaped grooves ...

Embodiment 2

[0037] The titanium tube welded in Example 1 (specification ф60.3×5.54mm, grade B861Gr.2) was tested for mechanical properties. The ambient temperature of the test was 24°C. The results are shown in Table 2 below:

[0038] Table 2 Test results of mechanical properties of welded titanium tubes

[0039]

[0040]Taking ASME as the testing standard, the above mechanical performance tests are qualified.

Embodiment 3

[0042] The titanium tube welded in Example 1 (specification ф60.3×5.54mm, brand B861Gr.2) was tested for mechanical properties. The ambient temperature of the test was 25°C. The hardness (HV10) of the test results is shown in Table 3:

[0043] Table 3 Hardness test results of welded titanium tubes

[0044]

[0045] With ASME as the testing standard, the above hardness test is qualified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com